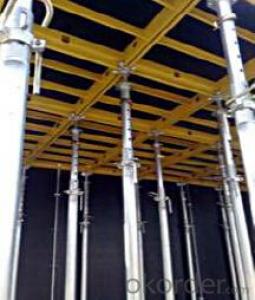

Aluminum-frame for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Aluminum-frame Formwork

Characteristics:

◆ The complete formwork system for slab casting, easy & quick assembly.

◆ Light panel weight, easy to carry.

◆ Economical, versatile & hi-speed formwork system; comes with a permissible slab

thickness of 400 mm.

◆ Working efficiency is greatly improved by fast erection and dismantlement.

◆ The panel can be supported by both props and scaffolding.

◆ High standardization with components.

- Q: How does steel formwork contribute to the strength of the structure?

- Steel formwork contributes to the strength of a structure in several ways. Firstly, steel is a strong and durable material, making it ideal for withstanding the pressures and loads that a structure may experience. This strength allows the formwork to support the weight of the concrete during the pouring and setting process, ensuring that it does not collapse or deform under the weight. Additionally, steel formwork provides excellent stability and support, which is crucial for the overall stability of the structure. The rigidity of steel formwork prevents any shifting or movement during the curing process, ensuring that the concrete sets in the desired shape and maintains its structural integrity. Moreover, steel formwork is highly resistant to moisture, chemicals, and extreme weather conditions. This resistance helps to protect the concrete from any potential damage or deterioration that may occur over time, ensuring the longevity and strength of the structure. Another essential aspect of steel formwork is its ability to create smooth and precise concrete surfaces. The use of steel panels and beams with smooth finishes allows for a high level of accuracy and precision in the construction process. This precision translates into a more robust and structurally sound finished product. Furthermore, steel formwork is reusable, which contributes to its cost-effectiveness and sustainability. The ability to reuse the formwork multiple times reduces construction costs and minimizes waste, making it an environmentally friendly option. In summary, steel formwork plays a crucial role in enhancing the strength of a structure. Its strength, stability, resistance to various elements, precision, and reusability all contribute to creating a durable and robust structure that can withstand the test of time.

- Q: What are the different types of steel formwork joints and connections?

- Construction commonly utilizes various types of steel formwork joints and connections. These encompass: 1. Butt Joint: This basic joint joins two formwork panels by placing them alongside each other and securing them with bolts or clamps. It is a straightforward and efficient method. 2. Lap Joint: In this joint, two formwork panels overlap and are fastened together with bolts or clamps. It offers greater strength and stability than a butt joint. 3. Corner Joint: Corner joints connect formwork panels at right angles, typically in wall or column corners. They can be created by overlapping panels or using specialized corner connectors. 4. T-Joint: T-joints occur when three formwork panels intersect at a right angle, with one panel forming the stem of the "T". They are frequently employed in beam or slab construction. 5. Hinged Joint: Hinged joints are useful when formwork panels need adjustable connections at specific angles. They enable flexibility in formwork assembly and alignment. 6. Wedge Joint: This joint involves inserting wedges into pre-cut slots or grooves in formwork panels. It ensures a secure and tight connection. 7. Tie Rod Joint: Tie rod joints connect formwork panels using threaded steel rods. They are often found in large-scale construction projects requiring high load-bearing capacity. 8. Pin Joint: Pin joints are formed by inserting steel pins into pre-drilled holes in formwork panels. They establish a rigid connection. Each joint or connection type offers distinct advantages and is selected based on project-specific requirements. Factors such as load-bearing capacity, formwork design, and ease of assembly and disassembly influence the choice of joint type.

- Q: How does steel formwork affect the overall constructability of the structure?

- Steel formwork can greatly enhance the constructability of a structure due to its strength, durability, and flexibility. It enables the construction process to be more efficient and precise, allowing for faster assembly and disassembly. The use of steel formwork also ensures consistent and high-quality concrete finishes, reducing the need for subsequent repairs or modifications. Additionally, steel formwork can be easily adapted to different shapes and sizes, enabling the construction of complex structures with ease. Overall, the use of steel formwork positively impacts the overall constructability of a structure by improving productivity, reducing construction time, and enhancing the final outcome.

- Q: Can steel formwork be used for both straight and curved walls?

- Yes, steel formwork can be used for both straight and curved walls. Steel formwork offers high strength and durability, making it suitable for shaping walls of various shapes and sizes. It is highly flexible and can be easily adjusted and customized to create both straight and curved walls. The steel formwork system allows for precise and accurate construction, ensuring that the walls are built to the desired specifications. Additionally, steel formwork is reusable, making it a cost-effective choice for both straight and curved wall construction projects.

- Q: What are the fire resistance properties of steel formwork?

- Steel formwork is known for its excellent fire resistance properties. Steel is a non-combustible material, which means it does not burn or contribute to the spread of fire. It has a high melting point, making it extremely resistant to heat and flames. In the event of a fire, steel formwork will not collapse or lose its structural integrity, providing a safe environment for workers and preventing the spread of fire to other areas. Additionally, steel formwork does not emit toxic fumes or smoke when exposed to high temperatures, unlike other construction materials such as wood or plastic. This is important for the safety of workers and occupants of buildings, as toxic fumes can be harmful and hinder evacuation efforts during a fire emergency. Furthermore, steel formwork has a low thermal conductivity, meaning it does not transfer heat easily. This property helps to contain the heat within the fire area and prevents it from spreading to adjacent areas. It also reduces the risk of structural damage caused by the expansion and contraction of materials due to heat exposure. Overall, the fire resistance properties of steel formwork make it a reliable choice for construction projects, especially in areas where fire safety is a crucial consideration. Its non-combustible nature, high melting point, lack of toxic fumes, and low thermal conductivity contribute to creating a safe and secure environment in the face of potential fire hazards.

- Q: What are the different types of formwork accessories used with steel formwork?

- There are several types of formwork accessories used with steel formwork, including form ties, formwork clamps, spreader bars, formwork brackets, formwork support systems, and scaffold brackets. These accessories play essential roles in ensuring the stability, alignment, and overall efficiency of the steel formwork during the construction process.

- Q: What are the common cost-saving strategies when using steel formwork?

- There are several common cost-saving strategies when using steel formwork in construction projects. 1. Reusability: One of the key advantages of steel formwork is its ability to be reused multiple times. By properly maintaining and storing the formwork after each use, it can be used for several projects, reducing the need for new formwork and ultimately saving costs. 2. Durability: Steel formwork is known for its durability and long lifespan. It can withstand high pressures and can be used for a longer duration compared to traditional formwork materials like timber. This durability reduces the need for frequent repairs or replacements, leading to cost savings in the long run. 3. Efficiency: Steel formwork allows for faster and more efficient construction compared to traditional formwork methods. The ease of assembly and disassembly, along with the use of hydraulic systems, enables faster construction cycles and reduces labor costs. Additionally, the precision and accuracy of steel formwork ensure minimal material wastage, further contributing to cost savings. 4. Safety: Steel formwork offers enhanced safety features compared to other formwork materials. It provides stability and structural integrity, which reduces the risk of accidents during construction. A safer working environment means lower insurance costs and potential legal liabilities, resulting in cost savings. 5. Reduced labor costs: Steel formwork is typically lighter and easier to handle compared to other materials. This reduces the number of workers required for installation and removal. Additionally, the speed and efficiency of steel formwork result in reduced labor hours, leading to cost savings. 6. Lower maintenance costs: Steel formwork requires minimal maintenance compared to other formwork materials. Regular cleaning and proper storage are typically sufficient to maintain its performance. This eliminates the need for expensive maintenance or repairs, resulting in cost savings over time. 7. Improved quality: Steel formwork ensures consistent quality in construction. It provides accurate dimensions and smooth finishes, reducing the need for additional finishing work. This saves both time and money, as there is no need for additional materials or labor to rectify imperfections. Overall, the common cost-saving strategies when using steel formwork revolve around its reusability, durability, efficiency, safety, reduced labor costs, lower maintenance costs, and improved quality. By considering these strategies, construction projects can optimize their budget and achieve significant cost savings.

- Q: Can steel formwork be easily customized?

- Certainly! Steel formwork offers great flexibility in customization. Its highly versatile nature enables it to be easily molded, shaped, and transformed into different configurations to meet the specific needs of any construction project. By cutting, bending, welding, and fabricating steel, customized formwork systems can be created to perfectly match the unique shape and dimensions of a structure. This adaptability allows for the construction of intricate geometries, curves, and patterns, making steel formwork suitable for a wide range of architectural designs. Moreover, the ability to reuse steel formwork multiple times enhances its customization capabilities and cost-effectiveness even further.

- Q: What are the common safety measures to be followed when using steel formwork?

- To ensure the safety of workers and the successful completion of construction projects using steel formwork, it is important to adhere to several safety measures. These measures include: 1. Proper training and education: All workers involved in the use of steel formwork should receive comprehensive training on its installation, usage, and dismantling. They must be knowledgeable about potential hazards and how to mitigate them. 2. Inspection and maintenance: Before utilizing steel formwork, it is crucial to thoroughly inspect it for any defects or damages. Any issues should be promptly addressed or the formwork should be replaced. Regular maintenance should also be performed to ensure its structural integrity. 3. Careful handling and storage: Steel formwork should be handled with caution to avoid injuries. It should be stored in a designated area, away from potential hazards or heavy machinery. 4. Use of personal protective equipment (PPE): To safeguard themselves from potential hazards or falling objects, workers should always wear appropriate PPE, such as safety helmets, safety goggles, gloves, and safety shoes. 5. Sufficient bracing and support: To prevent collapse or structural failure, steel formwork should be adequately braced and supported. This involves using the correct number and type of props or supports, as well as ensuring the formwork is level and plumb. 6. Secure and stable footing: Workers must have a secure and stable footing when working with steel formwork. This may necessitate the use of scaffolding or temporary platforms to provide a safe working surface. 7. Proper lifting techniques: When lifting or moving steel formwork, workers should employ correct lifting techniques to prevent strains or injuries. This may entail using lifting equipment, such as cranes or hoists, and ensuring an even distribution of the load. 8. Effective communication and coordination: Clear communication and coordination among workers is essential when utilizing steel formwork. This helps prevent accidents and ensures that everyone understands their roles and responsibilities. By adhering to these common safety measures, the risk of accidents or injuries when using steel formwork can be significantly reduced, resulting in a safer and more productive work environment.

- Q: Are there any specific design considerations for steel formwork construction?

- Yes, there are several specific design considerations for steel formwork construction. Firstly, the formwork should be designed to withstand the weight of the concrete and the pressure exerted during pouring. It should be structurally strong and rigid to prevent any deformation or collapse. Additionally, the formwork design should allow for easy installation, dismantling, and reusability, as steel formwork is often used in repetitive construction projects. Special attention should be given to the joints and connections to ensure stability and prevent leakage. Finally, proper surface finish and alignment should be considered to achieve the desired concrete finish.

Send your message to us

Aluminum-frame for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords