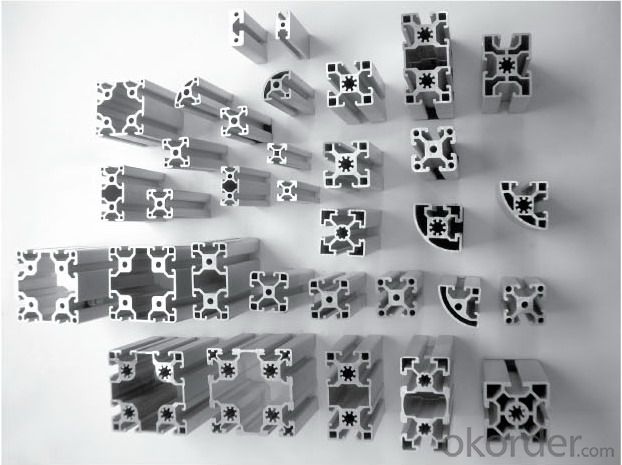

Aluminum Frame Extrusion Profiles for Light Application - Best Price and Quality Aluminium Circles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Circle for Light Application Best Price and Best Quality Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Circle for Light Application Best Price and Best Quality:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of theAluminium Circle for Light Application Best Price and Best Quality:

Aluminium Circle for Light Application Best Price and Best Quality Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: How much does aluminum mold need?

- To see the aluminum circle size and large extrusion machine for production, to determine how much the mold fee. Besides, the die fee is returned, provided that how many tons of products are reached.

- Q: This question asks if there are any health hazards linked to handling aluminum profiles.

- <p>Generally, working with aluminum profiles does not pose significant health risks. Aluminum is a lightweight, corrosion-resistant metal that is widely used in various industries. However, inhalation of aluminum dust or fumes over long periods may cause respiratory issues. Workers should use appropriate personal protective equipment (PPE) such as masks and gloves to minimize exposure. Additionally, aluminum can cause skin irritation in some individuals, so skin contact should be avoided. It's important to follow safety guidelines and maintain good hygiene practices when working with aluminum profiles.</p>

- Q: Can aluminum profiles be used for escalator steps?

- Typically, aluminum profiles are not employed for escalator steps. Escalator steps are specifically engineered to endure substantial weight and endure constant foot traffic, rendering them susceptible to elevated levels of stress and wear. Consequently, escalator steps are generally crafted from resilient materials like steel or sturdy composite materials, capable of withstanding heavy burdens and delivering enduring performance. Although aluminum profiles can find diverse applications in architectural or industrial contexts, they are infrequently utilized for escalator steps due to their relatively inferior strength and propensity for deformation under heavy loads.

- Q: This question asks about the effects of utilizing aluminum profiles in the construction industry on the environment.

- <p>The environmental impacts of using aluminum profiles in construction are multifaceted. On the positive side, aluminum is lightweight and strong, reducing the amount of material needed and potentially decreasing energy consumption in transportation. It is also recyclable, which can reduce waste and the need for raw material extraction. However, the production of aluminum requires significant energy, often from non-renewable sources, contributing to carbon emissions. Additionally, while recycling reduces environmental impact, it still consumes energy and can generate waste. The longevity and durability of aluminum can lead to less frequent replacement, reducing construction waste, but improper disposal can lead to pollution. Overall, the environmental impact depends on the balance between these factors and the specific practices of aluminum production and use in construction.</p>

- Q: What are the different bending and forming options for aluminum profiles?

- Some of the different bending and forming options for aluminum profiles include roll bending, stretch forming, press brake bending, and extrusion bending. These processes allow for the creation of various shapes and designs, offering flexibility and versatility in aluminum profile applications.

- Q: Is it possible to utilize aluminum profiles in regions with low temperatures?

- <p>Yes, aluminum profiles can be used in cold climates. Aluminum is a durable material with excellent resistance to corrosion and weathering, including low temperatures. It maintains its strength and does not rust or degrade in cold conditions. However, it's important to consider thermal expansion and contraction, as aluminum expands and contracts more than some other materials. Proper design and installation practices can mitigate these effects, making aluminum profiles suitable for use even in extreme cold environments.</p>

- Q: How are the aluminum and aluminum sections joined?

- Method for connecting aluminum section and aluminium section bar:The use of aluminum connecting piece.Welding: aluminum can be welded, and can be realized by argon arc welding or MIG welding. What welding process is adopted, depending on the specific workpiece.Cementation: bonding (bonding) is a method of making two adhesive joints by utilizing mechanical binding force, physical adsorption force and chemical bonding force produced on the join surface.

- Q: Do aluminum profiles come with any certifications?

- Yes, aluminum profiles often come with certifications such as the ISO 9001 quality management system certification, ISO 14001 environmental management system certification, and the RoHS (Restriction of Hazardous Substances) compliance certification. These certifications ensure that the aluminum profiles meet international standards for quality, environmental friendliness, and the absence of hazardous materials.

- Q: Can aluminum profiles be used for stage and event structures?

- Stage and event structures can indeed make use of aluminum profiles. Aluminum, being both lightweight and durable, is a widely utilized material in the construction industry for a range of purposes, including stage and event structures. Aluminum profiles possess versatility, allowing for easy shaping, cutting, and joining to create customized structures. With an excellent strength-to-weight ratio, they are well-suited for supporting heavy equipment and ensuring the safety of performers and audience members. Moreover, aluminum profiles can be powder-coated or anodized, providing both a decorative finish and protection against corrosion. This enhances the visual appeal and longevity of the structures. In conclusion, aluminum profiles are a popular option for stage and event structures due to their versatility, strength, and aesthetic qualities.

- Q: 30*40 how much aluminum meter?

- 30*40 aluminum tube color of grain price is generally about 13.6-19.8.

Send your message to us

Aluminum Frame Extrusion Profiles for Light Application - Best Price and Quality Aluminium Circles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords