Reynolds Wrap Aluminum Foil for Beer Bottle Neck Label

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

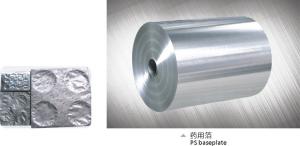

1.Description of Aluminum Foils for Beer Bottle Neck Label

High tensile strength aluminum foil made from special high quality aluminum foil, coated with aggressive solvent-based acrylic adhesive, which provide strong stickiness, good peel strength, high tensile strength and great ageing resistance.

Base Material: aluminum foil tape. Thickness can be customized

Release Paper: Single shield or according to request.

Adhesive: acrylic pressure-sensitive adhesive

Core: Φ76mm(±1,0)mm

2. Specifications of Aluminum Foils for Beer Bottle Neck Label

Alloy: 8011

Temper: O

Thickness: 0.01-0.012mm

Width: 200-1500mm

Core I.D.: 3" or 6"

Max OD: 700mm

3. Applications of Aluminum Foils for Beer Bottle Neck Label

Building, curtain wall, ceiling, panels, transformers, food packaging, air conditioning, condenser, air filter, refrigerators, washing machines, solar energy, automobile manufacturing, ship manufacturing, machinery manufacturing, electric equipment such as cosmetic packaging, machinery manufacturing industry, can also be used in power plants, chemical anti-corrosion insulation in petrochemical industry, etc.

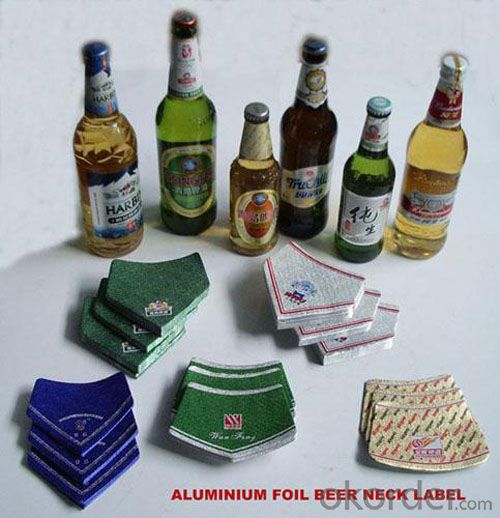

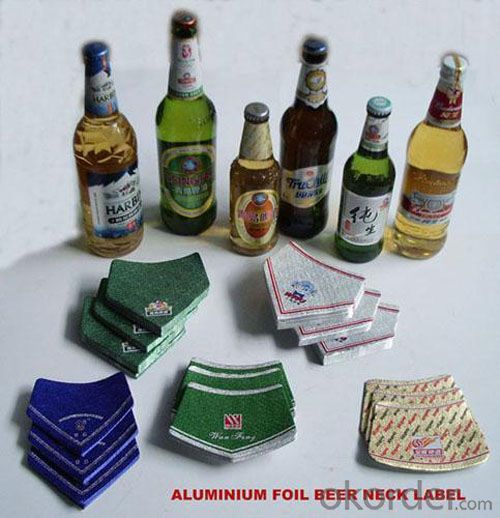

4. Images

5. FAQ

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our foil price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your Delivery term?

We do FOB, CFR, CIF, we don't do DDP.

5) Could you offer sample?

We could offer sample as your requirement. A4 Size sample is free for you, for bigger roll sample, it depends on the coil weight.

- Q: I have some copper bottom pans that are non-magnetic and want to know if they are aluminum or austenitic stainless steel (the only steel that is non-magnetic)Is there an easy way to tell?

- Sleeping bag, pocket knife, lighter and your good to go.

- Q: I have 3 little plants in my fish tank. They didn't have that metal thing at the pet store that weighs them down and holds them together so my goldfish keep nibbling on them and pulling them up out of the gravel. Can I put pliable aluminum around my plants?

- don't okorder /.. goldfish will eat pretty much all live plants, which is why they should are best in with silk plants or rock decor only. even with lead weights (which shouldn't be left on the plants with the sponge wrap as it can cause the roots to rot), the goldfish could probably still pull them up.

- Q: I could never make a chicken taste as good as this pre-cooked chickenI saw a couple recipes for uses of it wanted to know your input? Some say top a salad with it, others say to make soupI'm curious of further suggestions for reusing this delicious roastAll suggestions recipes are welcome!

- Because they saw it in a movie and it looks coolSupposed to seat all the ammo to the rear of the mag, in actuality all it does is break the welds and destroy the magazineWhen you put the rounds in the magazine they should already be mostly in line, and those that aren't will not create a misfeedWelds are on the back and they are not just pressed togetherThat marine has obviously not been an armorer long if hes never seen one breakYes the first round can be pushed forward some which would make the mag not load, however banging it on your head will not push it back as its got too much tension from the rounds below pushing it onto the feeding claws of the magPushing it back with your fingers is effective without looking like a deedeedee

- Q: My mom and I were just cleaning out from behind our washer dryer for the first time since we moved inAfter pulling the dryer out some we discovered that the big silver aluminum looking tube that runs from the wall to the dryer is completely dilapidatedThe people who lived here before us used to lock their cat in the laundry room and the hose has tons of little holes from the cats claws and it's almost torn in two at one spotWhat is this hose called and how do you replace it? Thanks!

- go shoppinggg, and spend some cashhh(:

- Q: A sample of metal shavings with a mass of 0.0250 g contains a mixture ofaluminum and magnesium, though it is not known how much of each metal is present.To determine the composition of the mixture, the metal sample is reacted completelywith hydrochloric acidThe hydrogen gas produced is collected over water on a daywhen the temperature is 23.0 oC and the atmospheric pressure is 755.0 TorrAfter thereaction, the water level in the collection tube was 25.5 cm higher than the water level inthe beakerThe volume of gas collected under these conditions was measured at 30.48mL.aIs the pressure of the gas inside the collection tube higher than or lower than theatmospheric pressure? ExplainWhat is the pressure of the gas inside the gascollection tube?bWhat is the partial pressure of just the hydrogen gas?cHow many total moles of hydrogen gas are produced?dDetermine the mass of each metal present in the original sample.

- ait is lowerthe gas pressure in the tube p2 plus the pressure of 25.5cm of water p1 is balanced by the atmospheric pressure p0, because pressure in a fluid like water is the same at points on the same horizontal levelp2+p1p0water pressure p1 density x g x height 1000 kg/m^3 x 9.8 m/s^2 x 0.255 m 2499 N/m^2.

- Q: We had a couple of bags of gift wrap that we put out for the recycler to pick up and they said no because it has already been recycled.

- Almost all paper can be recycled today, but some types are harder to recycle than othersPapers coated with plastic or aluminium foil, and papers that are waxed, pasted, or gummed are usually not recycled because the process is too expensiveGift-wrap paper also cannot be recycled due to its already poor quality.

- Q: Should the aluminum foil fiberglass pipe be insulated?

- South south wind pipe system, also known as the bag cloth duct, air duct, air duct, fabric fabric air distributor is a flexible air distribution system is composed of special woven fabric (Air Dispersion), is to replace the traditional air pipe, air valve, diffuser, insulation material such a sent air terminal system.

- Q: aseptic technique

- Filter papers - wrap them individually or in groups of maybe 5 in aluminum foil Pipette tips in their matching box conical flask, with (cotton?) stopper, cover stopper with alum foil distilled water, in its bottle with the screwcap sligthly open all go into the autoclave the filter paper will be wettish and will need to dry out, maybe stick it in an oven after sterilizing

- Q: I am considering replacing my aluminum single frame windows with double pane energy efficient windows.One of the manufacturers I have contacted says quot;I don't put Argon gas between the panes because the gas will leak out in a year or twoquot;How important is Argon or another inert gas between the panes a far as energy efficiency is concerned? Also, some installers take out the entire existing aluminum frame while others insist to remove the entire frame is not a good idea and they leave the frame and install the new windows over the existing frameWhich installation method is recommended?

- I think its great that you are upgrading your windows! Argon gas will leak out over the course of 5 years or soI think the window companys use argon to help them achieve better energy ratings when they are certified by the NFRC and AAMAThat being said, I would not waste money on argon filled unitsSeveral manufacturers have specifically designed windows to install directly over your exsisting window framesAs long as your window guy is using one of these replacement windows, its ok for them to leave your old frames in placeif they are using a window designed for new construction, then they should remove the old frames for proper fit and weather tightness,

- Q: Please write the balanced net ionic equations for the following reactionsIf Someone could please go through one problem STEP-BY-STEP and leave just a answer for the other two SO I CAN Learn it myselfit would be greatly appreciated!!!! A strip of Zinc is placed in a solution of nickel(II) nitrateSolid Aluminum hydroxide is added to a concentrated solution of potassium hydroxideEthyne (acetylene is burned in air.

- OK, here is step by step for first one: We start by creating our molecular equationsHere is the equation for first one: Zn + Ni(NO3)2 - Ni + Zn(NO3)2 This equation is already balanced so we do not have to worry about thatOnce we have this we worry about the solubles and insolublesAs you may know, anything with a nitrate ion is automatically solubleThis means we have to split it into ions Zn is a solid (strip of zinc) and Ni is too So when you break into ions: Zn(s) + Ni(aq) + 2NO3(aq) - Ni(s) + Zn(aq) + 2NO3(aq) Now cancel out your spectator ionsThese are ions that are exactly the same on both sidesThe only spectator ion in this equation is 2NO3Cancel it and you are left with: Zn(s) + Ni(aq) - Ni(s) + Zn(aq) - FINAL NET IONIC I leave the other two to you.

Send your message to us

Reynolds Wrap Aluminum Foil for Beer Bottle Neck Label

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords