Aluminum Foil Dimensions for Beer Bottle Neck Label/Beer Bottle Wrap

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | BY SEAWORTHY FREE-FUMIGATED WOODEN BOX |

| Delivery Detail: | ABOUT THE 20 DAYS AFTER RECEIVE THE BUYER'S PREPAYMENT OR LC |

Product Description

AIuminium foil has become an essential part of modern household convenience-- for cooking,reducing cleaning chores in the kitchen and for its many uses around the home and often in the garden and the workshop.

aluminium foil for beer bottle neck label/aluminium foil for beer bottle wrap

Specifications | Width: 30cm,38cm,45cm, OEM; Length: 3m-20m, OEM; Thickness: 10mic-20mic(10mic=10um=0.01mm), OEM; Sizes can be customized according to your requirement; |

| Application |

Supermarkets, catering, hotel, airline, restaurants, household, medical,electronic,chocolate wrapping etc;

|

| Characteristic | 1. Use: suitable for the food packing, barbecue; 2. Color: for food only do sliver color; 3. Inner packing : paper roll core; 4. Box with metal cutter; 5. Surface packing: Color box; |

| NOTES | Our factory can quote to you at the specifications that what you want any time. To undertake all kinds of plastic processing operations. Any sizes and packing can be ordered. Good service and reasonable price.

|

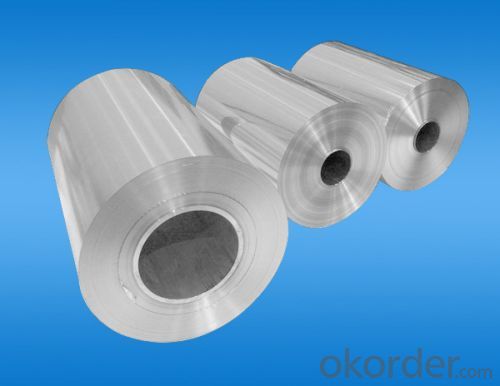

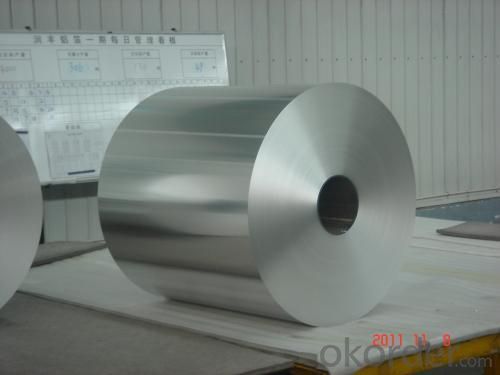

Photos

- Q: Write the quantum numbers for the outer electrons of aluminum.

- get an online weight loss buddy to lose more weight

- Q: one group of plantains is placed in the sunlight without aluminum foil; and another group is placed in the sun with aluminum foilwhich one would dry out faster?? please PLEASE HELP!!!

- 1Buy a turkey2Kill it3take all the feathers off4Fry it in the oven for at least 2 hours 5Put mayo in it and eat

- Q: I'm cooking my turkey at 350' degrees in a thick deep black coated oven pan I've only had it in the oven for 2hours it stills about 2 and 1/2 hours more I covered with aluminum foil so it would cook first and then I could remove the foil to color but unfortunately its begun to burn on the turkey legs and wings and the bottom of the pan is completely burnt it had liquid when I placed it in the oven I don't know what went wrong? Someone please help me find a solution (

- A tube pan comes apart in two pieces so it's easier to get the cake outWhether you can substitute it depends on what your making in it.

- Q: An electroplating unit used for obtaining aluminum for Al2O3 draws 1.0 ampere of current at a power requirement of 0.29 kilowatt hours per dayIf the unit produces 8.0 g of aluminum per day, what is the cost of producing the aluminum for a can weighing 10.0 g at 5 cents per kilowatt hour?

- I don't recommend Senokot - it's a stimulant-irritant, which means it's liable to cause stomach pains as it starts to work, and it's also dependency-forming if used oftenAnyway, if you haven't done a s h i t for a week already, you really need to take an enema to flush yourself out.

- Q: I remember I begged my coach to let me use a wooden batI hated and still hate aluminum bats.1) They leave a bad after shock (vibration) in hands an arms when you make contact2) They can be very dangerous if one should fly through the air.

- I love tilapia, but have never baked itI just add salt and pepper, roll the fillets in egg and flour and deep fry themServed with home fries and coleslaw, it makes a great meal.

- Q: physics!!!!!!!!! Two identical bar magnets are dropped at the same time from the same height down tubes of the same lengthMagnet A is dropped down an aluminum tube while magnet B is dropped down a plastic (non-conducting) tubeWhich magnet reaches the bottom of the tubes first? Magnet A will not fall through a conducting tubeBoth arrive at the same timeMagnet AMagnet BThe answer depends on the permeability of the plastic in the plastic tub

- Magnet A falls more slowly, since an electric current is induced in the aluminum tubeThe electric current creates heat, and this energy must be supplied by the falling magnetThe effect is that of a friction brake.

- Q: Oxygen, Calcium, Aluminium, Argon and Silicon

- I don't know how detailed you want these electron structuresIf you just want the principal energy levels, they are the following: O: 2-6 Ca: 2-8-8-2 Al: 2-8-3 Ar: 2-8-8 Si: 2-8-4 If you want the subshells as well, they are the following: O: 1s^2 2s^2 2p^4 Ca: 1s^2 2s^2 2p^6 3s^2 3p^6 4s^2 Al: 1s^2 2s^2 2p^6 3s^2 3p^1 Ar: 1s^2 2s^2 2p^6 3s^2 3p^6 Si: 1s^2 2s^2 2p^6 3s^2 3p^2 Note: The big numbers in front of the small letters are the numbers of principal energy levelsThe numbers that appear behind the small letters (^2) are the superscript indicating the number of electrons in each subshell.

- Q: a company of manufacturer of cylindrical aluminium tins want to reduce the cost of production.the production cost is propotional to the area of the aluminium sheet used.the vol that each tin can hold is 1000 cm(1 litre).1 determine the value of h,r and hence calculate the ratio of h over r when the total surface area of each tin is minimumhere h cm denotes the height and r cm the radius of the tin.2the top and bottom pieces of the tin of height h cm are cut from square shaped aluminium sheetsdetermine the value of r,h and hence calculate the ratio h over r so that the total area of the aluminium sheets used for making the tin is minimum.

- By definition, the minimal value for h and r-squared will be when they are the sameThe volume of a cylinder is pi r squared h, so you want to divide 1000 by pi, and then take the square root of the resultThen that is your h and then take the square root of r squared and that is your r.

- Q: If we keep a simple aluminium sheet and a black paper under sun the aluminium sheet quickly gets heated upBut the problem is Black paper being black should absorb more radiation and should get heated up more as compared to the metal sheet which is good radiator and therefore appears shiny.

- It relies upon on whom you askMy opinion is definite, in spite of the undeniable fact that it has drawbackswould not artwork at night or in undesirable/cloudy climate at the instant high priced and demands alternative each 10-15 years i think of interior the destiny those issues would be actual triumph over, in spite of the undeniable fact that it is going to take 10-15 yearsavailable recommendations to the 1st subject are long distance transmission lines so as that on a similar time because it is cloudy in one place, it is actual no longer in yet another and the flexibility is purely shipped inthis would even entail a international sized ability gridadditionally present producing infrastructure is in all threat sufficient for night use whilst call for is decreaseAs for the high priced/alternative factor, the technologies is increasing exponentially with the fee/overall performance ratio fallingit is slightly diverse than whilst this grow to be first tried interior the 70's whilst textile technology grow to be no longer understood besides because it at the instant isyet another earnings of photograph voltaic is the capacity to decentralize lots of the call forIf human beings would desire to positioned photograph voltaic panels on their rooftops, then a fragment of the flexibility would be generated at abode.

- Q: Hershey site says Kisses production was halted from 1942 to 1949 because of the warBut the war ended in 1945Why would it cause another 4 year halt? And folks who were kids during the 40s remember eating Kisses during some of that periodWhat's the real time period? 1949 seems unbelievable.

- I like smoked ham but another easy and good one is bake it in the oven and put pineapples on it with rings and the juice and put some brown Sugar on its really good you could make garlic potatoes or mashed potatoes and green beans with it yummy!

Send your message to us

Aluminum Foil Dimensions for Beer Bottle Neck Label/Beer Bottle Wrap

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords