Aluminum EN AW-5383 Sheets from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of EN AW - 5383 Aluminium Sheets from China Description

EN AW - 5383 Aluminium Sheets from China is one semi-finished aluminium material. The alloy AA5383 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 5383 Aluminium Sheets from China

EN AW - 5383 Aluminium Sheets from China | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 5383 Aluminium Sheets from China

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 5383 Aluminium Sheets from China

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 5383 Aluminium Sheets from China

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

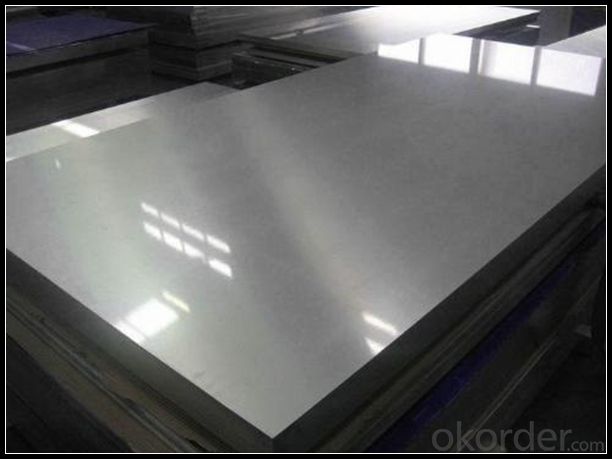

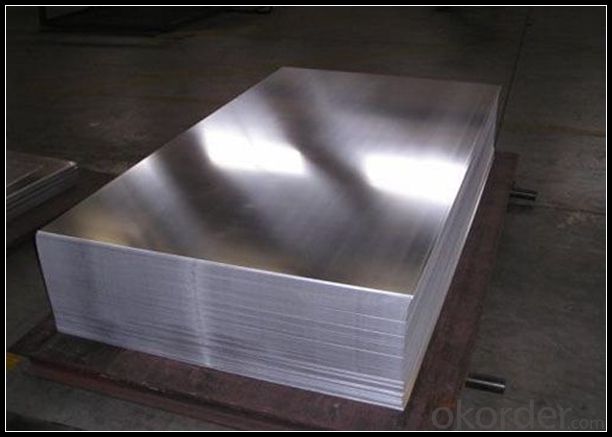

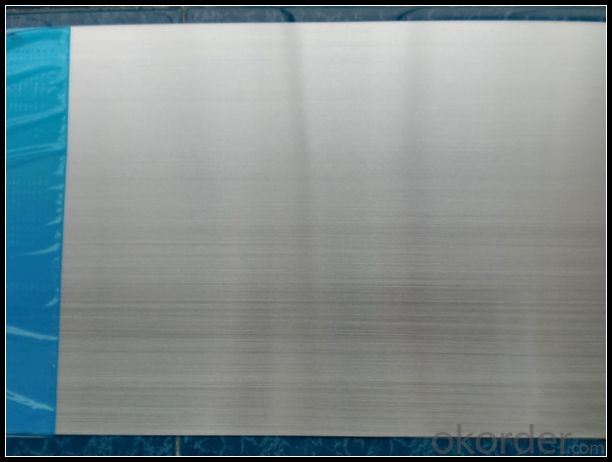

6. Image of EN AW - 5383 Aluminium Sheets from China

7. Package and shipping of EN AW - 5383 Aluminium Sheets from China

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is it possible to utilize aluminum as a component in battery technology?

- <p>Yes, aluminum can be used in batteries. Aluminum-air batteries are a type of metal-air battery that uses aluminum as the anode. These batteries have a high energy density and are lightweight, making them suitable for certain applications. However, they also have challenges such as the need for a specific electrolyte and issues with aluminum corrosion, which limit their practical use compared to more common battery technologies like lithium-ion batteries.</p>

- Q: What characteristics distinguish pure aluminum from its alloyed forms?

- <p>Pure aluminum is a soft, lightweight, and highly malleable metal with good electrical and thermal conductivity. It is often used for its corrosion resistance and is relatively inexpensive. Aluminum alloys, on the other hand, are made by combining aluminum with other elements like copper, magnesium, silicon, or zinc to enhance its properties. These alloys are stronger, more durable, and can be tailored for specific applications, such as in aerospace, automotive, or construction. They offer improved strength-to-weight ratios, better resistance to heat and wear, and can be anodized for enhanced surface properties. While pure aluminum is more ductile and easier to weld, aluminum alloys provide greater versatility in terms of mechanical properties and performance.</p>

- Q: This question asks about the methods used to determine the hardness of aluminum material.

- <p>The hardness of aluminum can be measured using various standardized tests. The most common methods include the Brinell Hardness Test, where a hard steel or carbide ball is pressed into the aluminum surface, and the Vickers Hardness Test, which uses a diamond pyramid indenter. The Rockwell Hardness Test is also used, applying a diamond cone or steel ball to the surface. The hardness is quantified by the depth of the indentation, and the results are expressed in specific hardness units like BHN (Brinell Hardness Number), HV (Vickers Hardness), or HR (Rockwell Hardness). These tests provide a measure of the material's resistance to deformation, which is crucial for applications requiring strength and durability.</p>

- Q: This question asks for various methods that can be used to recycle aluminum.

- <p>Recycling aluminum can be done through several methods, including mechanical recycling, which involves melting and reprocessing aluminum without altering its chemical properties. This is the most common method due to its efficiency and cost-effectiveness. Another method is chemical recycling, where aluminum is treated with chemicals to break it down into its constituent elements, which can then be repurposed. Additionally, aluminum can be recycled through a process called hydrometallurgical recycling, which uses aqueous solutions to extract aluminum from waste. Finally, sorting and collection play a crucial role in ensuring that aluminum waste is directed to appropriate recycling facilities where these methods can be applied.</p>

- Q: This question asks for examples of industrial processes that incorporate the use of aluminum.

- <p>Aluminum is widely used in various industrial processes due to its lightweight, corrosion resistance, and high strength-to-weight ratio. Some key industrial processes that utilize aluminum include the automotive industry for manufacturing car parts, the aerospace industry for aircraft construction, the construction industry for building materials, the packaging industry for food and beverage cans, and the electronics industry for components in devices. Aluminum is also used in the manufacturing of machinery, electrical equipment, and transportation equipment. Its versatility makes it a crucial material in many industrial applications.</p>

- Q: Is it safe and effective to use aluminum foil to create a sandwich in a microwave oven?

- <p>No, you should not use aluminum foil to make a sandwich in a microwave oven. Aluminum foil can cause sparks and potentially start a fire due to its reflective properties and the microwave's electromagnetic radiation. It can also damage the microwave's interior. Instead, use microwave-safe containers or wraps designed for microwaving.</p>

- Q: This question asks if there are differences in how long different types of aluminum cookware can last.

- <p>Yes, there are differences in the durability of different types of aluminum cookware. Anodized aluminum cookware is more durable and resistant to scratches and corrosion compared to non-anodized aluminum. Cast aluminum cookware is heavier and more durable than aluminum clad cookware, which is a layer of aluminum bonded to a stainless steel core. The thickness of the aluminum also affects durability, with thicker aluminum being more resistant to warping and lasting longer. Proper care and maintenance also play a significant role in the longevity of aluminum cookware.</p>

- Q: This question asks for a brief overview of the characteristics or qualities of aluminum nitride, a chemical compound.

- <p>Aluminum nitride (AlN) is a covalent, ceramic material known for its exceptional properties. It has a high thermal conductivity, which is about two-thirds that of copper, making it useful in electronics for heat dissipation. It's also an electrical insulator, exhibiting high electrical resistivity. Aluminum nitride is characterized by its high thermal stability, resistance to thermal shock, and excellent mechanical strength. It's chemically inert, resistant to most acids and alkalis, and has a high melting point of approximately 2200掳C. These properties make it suitable for applications in high-temperature electronics, as a substrate for semiconductor devices, and in the automotive industry for heat sinks and other heat management components.</p>

- Q: This question asks for a comparison of the positive and negative aspects of using aluminum as a material.

- <p>Aluminum has several advantages, including its lightweight nature, making it ideal for transportation and construction. It is also highly recyclable, with the recycling process requiring less energy compared to many other materials. Additionally, aluminum is corrosion-resistant, which extends the lifespan of products. On the downside, aluminum is less strong than some other metals, which can limit its use in certain applications. It also has a high thermal conductivity, which can be a disadvantage in situations where insulation is needed. Moreover, aluminum production is energy-intensive, contributing to environmental concerns.</p>

- Q: This question asks about the steps involved in preparing aluminum foil for use in food packaging.

- <p>Aluminum foil for food packaging is processed through several steps. First, aluminum ingots are melted and then rolled into thin sheets. The sheets are cleaned to remove any impurities and coated with a thin layer of food-grade protective coating to prevent any chemical reactions with the food. Next, the sheets are cut into rolls or sheets of standard sizes. The aluminum foil is then inspected for quality, ensuring it is free from defects and safe for food contact. Finally, it is packaged and shipped to manufacturers who use it to wrap or package food products.</p>

Send your message to us

Aluminum EN AW-5383 Sheets from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords