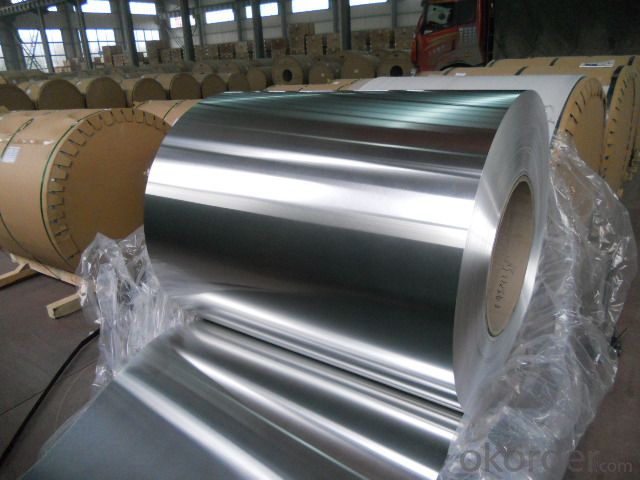

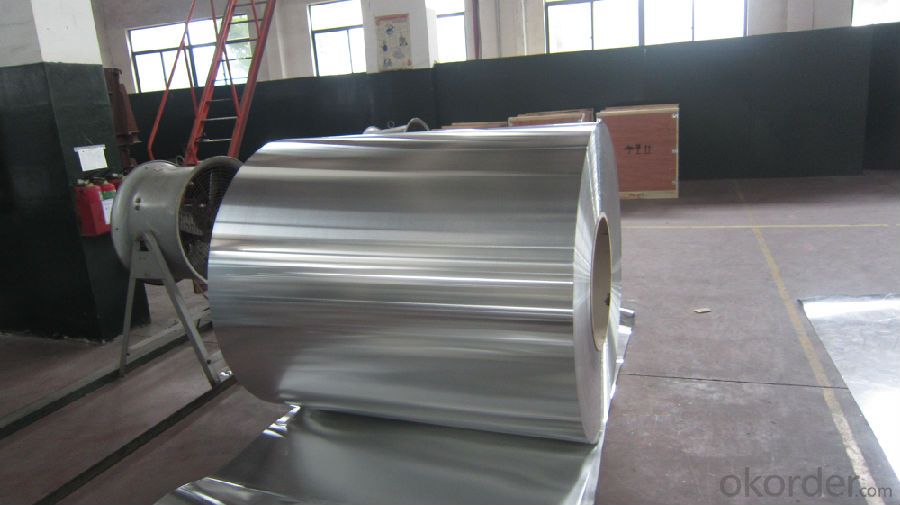

Aluminum Coil Material - 1060, 1100, 1200 O Aluminum Strip Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1) alloy number 1050 1060 1100 1200 3003 5052 5754 6061 8011.

2) temper available O H12 H14 H16 H18.

3) application: decoration, interior wall

4) thickness: 0.15--2mm

5) width: 2200mm max

6) production treatment: cold rolled or hot rolled.

7) surface appearance: flat clean surface no whole, scratch, oil dirty and oxidation.

8) cutting edge: neat cutting edge no burrs.

Chemistry Composition & Mechanical Properties

alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

1050 | 0.250 | 0.400 | 0.050 | 0.050 | 0.050 | - | 0.050 | 0.030 | 99.5 |

1060 | 0.250 | 0.350 | 0.050 | 0.030 | 0.030.- | - | 0.050 | 0.030 | 99.6 |

1070 | 0.200 | 0.250 | 0.040 | 0.030 | 0.030 | - | 0.040 | 0.030 | 99.7 |

1100 | Si+Fe:0.95 | 0.05-0.2 | 0.050 | - | - | 0.100 | - | 99.0 | |

FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: How do aluminum coils compare to other types of coils (e.g., copper)?

- Aluminum coils generally have a lower cost compared to copper coils, making them a more budget-friendly option. However, copper coils tend to have better heat transfer properties and are more durable, which can result in improved system performance and longer lifespan. The choice between aluminum and copper coils depends on factors such as budget, desired efficiency, and specific application requirements.

- Q: How are aluminum coils used in the production of electrical conductors?

- Aluminum coils are widely used in the production of electrical conductors due to their excellent electrical conductivity and lightweight properties. These coils are typically made from high-grade aluminum alloy, which ensures optimal electrical performance. In the production process, aluminum coils are first formed into thin, flat strips. These strips are then further processed through various techniques such as rolling, annealing, and drawing to achieve the desired shape and dimensions of the electrical conductor. Once the aluminum coil has been processed and formed, it is typically coated with a thin layer of insulating material, such as enamel or varnish, to prevent electrical leakage and ensure proper insulation. This coating also protects the conductor from corrosion and other environmental factors. Aluminum coils are commonly used in the production of electrical conductors, such as wires and cables, due to their high conductivity and ability to efficiently carry electrical current. They are especially preferred in applications where weight is a crucial factor, such as in the aerospace and automotive industries. Furthermore, aluminum coils offer cost advantages compared to other materials, making them a popular choice for electrical conductor production. Their lightweight nature also allows for easier installation and handling, reducing labor costs and time. Overall, aluminum coils play a vital role in the production of electrical conductors, providing excellent electrical conductivity, lightweight properties, and cost advantages. Their versatility and efficiency make them a preferred choice in various industries where electrical conductivity is crucial.

- Q: How to calculate the wall thickness with the gross weight of aluminum coil known?

- Gross weight*density=volume volume÷(aluminum sheet *width)=thickness

- Q: We are working on a new aluminum fixture. It is basically an aluminum spine with many 6061-T6 pins sticking out. Currently we drill the holes inside the spine and hammer the 5/32 6061-T6 pins inside. Is there anyway to cast aluminum with many 6061-T6 pins embedded (they will stick out after the casting)?

- How long are the pins? have you considered casting the pins along with the rest of the part? or is that what you are asking, it sounds, like you are talking about loading pins into the mold and having the cast spine bond with them. What casting process are you using, or are you even using a casting now, or is the spine currently rolled or extruded shapes? As mentioned on RCM, the pins will no longer be T6 after casting, if you need the T6 temper the part will have to be heat treated.

- Q: Is it possible to use aluminum coils for storage purposes?

- <p>Yes, aluminum coils can be used for storage, particularly for certain applications. They are often used in HVAC systems and electrical wiring due to their conductivity and flexibility. For general storage, aluminum coils may be suitable for winding and storing cables, wires, or similar materials. However, for storing items that require a specific environment or have weight concerns, it's important to consider the coil's strength and whether it can provide the necessary support and protection. Always ensure that the storage method complies with safety standards and the material's properties.</p>

- Q: Can aluminum coils be used in solar energy systems?

- Certainly, solar energy systems can utilize aluminum coils. Aluminum is widely employed in the fabrication of solar panels and solar energy systems owing to its remarkable qualities. Lightweight, durable, and possessing excellent thermal conductivity, aluminum coils are perfect for dispersing heat away from solar cells. Moreover, aluminum's resistance to corrosion is essential for outdoor deployments, where solar panels face diverse weather conditions. By incorporating aluminum coils into solar energy systems, the efficiency and lifespan of the panels are enhanced, thus augmenting the efficacy and sustainability of solar energy generation.

- Q: How do aluminum coils compare to copper coils in terms of performance?

- Aluminum coils and copper coils are two common types of heat exchanger coils used in heating, ventilation, and air conditioning (HVAC) systems. While both materials are effective in transferring heat, they do differ in terms of performance. Copper coils have long been the preferred choice for HVAC systems due to their superior heat transfer properties. Copper is an excellent conductor of heat, allowing for efficient transfer of thermal energy. This means that copper coils can cool or heat the surrounding air more effectively, resulting in faster and more efficient temperature control. On the other hand, aluminum coils are less efficient in terms of heat transfer compared to copper coils. Aluminum is a poorer conductor of heat, which means that it requires a larger surface area to achieve the same level of heat transfer as copper. Consequently, aluminum coils tend to be larger in size to compensate for their lower heat transfer capabilities. However, aluminum coils do have some advantages over copper coils. Firstly, aluminum is a lightweight material, making it easier to handle and install. This can be particularly beneficial in situations where weight restrictions or handling limitations are a concern. Secondly, aluminum coils are more resistant to corrosion compared to copper coils. Copper is prone to corrosion over time, especially in environments with high humidity or exposure to certain chemicals. Aluminum, on the other hand, naturally forms a protective oxide layer that helps prevent corrosion. This can result in longer-lasting coils and a lower likelihood of refrigerant leaks. In summary, while copper coils offer superior heat transfer capabilities, aluminum coils have their own advantages such as lighter weight and better corrosion resistance. The choice between aluminum and copper coils ultimately depends on the specific requirements of the HVAC system, including the desired performance, budget, and environmental factors.

- Q: Aluminum is directly below Mg. If aluminum is oxidized so readily, then how can we make planes or ships out of it and they don't fall apart after a few months or years?

- Yes aluminum does oxidize just like any other metal. The difference is that aluminum oxidizes the same color as the metal therefore you cannot tell that is oxidizing. Once is oxidizes a little bit, the oxidize protects the metal and it does not oxidize any more.

- Q: What is the typical lifespan of an aluminum coil?

- The typical lifespan of an aluminum coil can vary depending on factors such as usage, maintenance, and environmental conditions. However, with proper care and regular maintenance, an aluminum coil can last anywhere from 20 to 30 years or even longer. This lifespan can be extended by keeping the coil clean, ensuring proper ventilation to prevent moisture buildup, and addressing any damages or issues promptly. Additionally, factors such as exposure to harsh weather conditions, chemicals, or corrosive environments can impact the lifespan of an aluminum coil. It is important to consult with manufacturers or industry professionals for specific information regarding the expected lifespan of a particular aluminum coil in different applications.

- Q: Can aluminum coils be used in vacuum applications?

- Yes, aluminum coils can be used in vacuum applications. Aluminum is a commonly used material in vacuum systems due to its excellent properties such as low outgassing, high thermal conductivity, and good corrosion resistance. These properties make aluminum coils suitable for various vacuum applications, including but not limited to, vacuum chambers, vacuum pumps, cryogenic systems, and particle accelerators. However, it is important to note that aluminum can be reactive with certain gases or chemicals, so it is essential to consider the specific requirements and compatibility of the vacuum application before using aluminum coils.

Send your message to us

Aluminum Coil Material - 1060, 1100, 1200 O Aluminum Strip Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords