Aluminum Coil Goodman 0270a00983 - Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

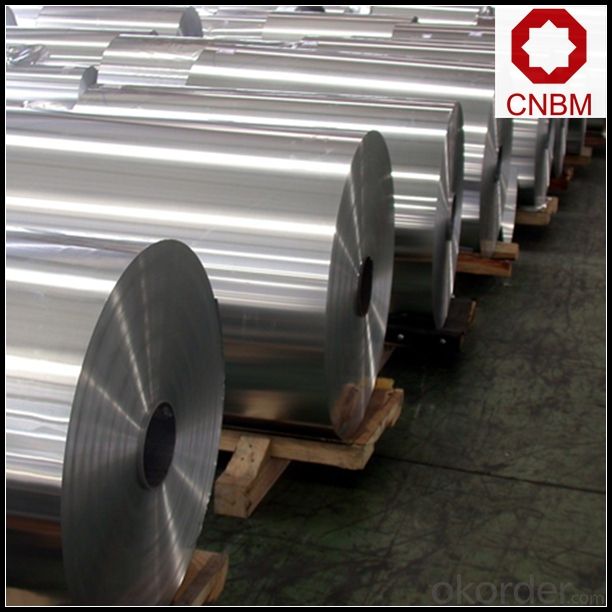

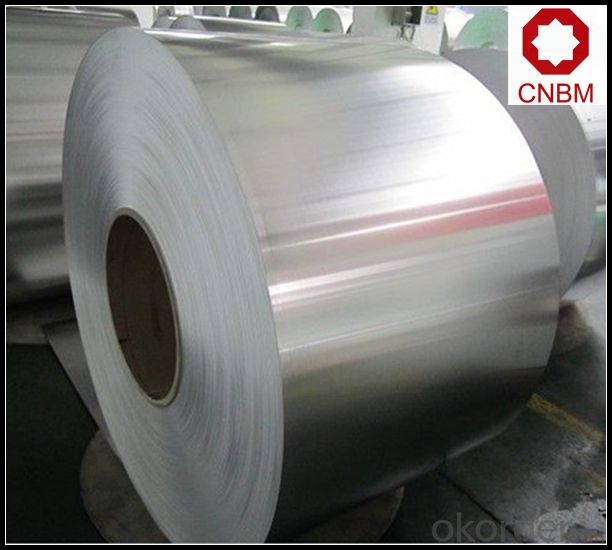

5. Image of Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

6. Package and shipping of Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are there any environmental benefits to using aluminum coils?

- Yes, there are several environmental benefits to using aluminum coils. Firstly, aluminum is a highly sustainable material as it is 100% recyclable without losing its original properties. This means that using aluminum coils helps reduce the demand for mining and extracting new raw materials, reducing the environmental impact associated with these processes. Additionally, recycling aluminum requires only about 5% of the energy needed to produce primary aluminum, resulting in significant energy savings and reduced greenhouse gas emissions. Moreover, aluminum coils have a longer lifespan compared to other materials commonly used in coils, such as copper or steel. This durability means that fewer coils need to be manufactured and replaced over time, resulting in less waste generation and lower overall environmental impact. Furthermore, aluminum is corrosion-resistant, which eliminates the need for additional treatments or coatings that may contain harmful chemicals. This reduces the release of potentially hazardous substances into the environment during the manufacturing and use of aluminum coils. Lastly, aluminum is lightweight, which contributes to lower transportation costs and energy consumption during distribution. This aspect decreases fuel consumption and associated emissions, reducing the overall carbon footprint of using aluminum coils. Considering these factors, the use of aluminum coils provides significant environmental benefits, including reduced resource extraction, energy conservation, waste reduction, and lower emissions.

- Q: Is it advisable to use a hammer to open a stuck aluminum coil?

- <p>Using a hammer to break open an aluminum coil that is stuck closed is not recommended. Aluminum is a soft metal and can be easily damaged by blunt force. Instead, try using pliers or a screwdriver to gently pry open the coil. If the coil is rusted or stuck due to other reasons, applying a penetrating oil or lubricant might help loosen it without causing damage. Always prioritize safety and the preservation of the material when attempting to open or unstick objects.</p>

- Q: I was wondering if you could mold clay into a sphere then fill it with aluminum. Then put it over a fire and wait until the aluminum melts then put it in a freezer and it would come out as a sturdy, aluminum sphere. Thanks!

- Do not try this at home! Seriously, this is exactly the kind of process that is used for casting metals. However, you need to have very strong molds with no cracks in them. Also, aluminum presents special problems. Solid aluminum does not corrode the way iron does, because it very quickly forms a protective tough layer of aluminum oxide. But molten aluminum can catch fire, with devastating consequences.

- Q: I was told today that taking aluminium inside your body greatly increases the chance of getting alzheimers as they destroy cells. Is this true?If so, then what foods contain aluminium?Thanks in advance :)

- I hadn't heard of any specific foods, but I have heard that deodorants that have aluminum in them had been linked to Alzheimers.

- Q: Can aluminum coils be used for seamless gutters?

- Seamless gutters can indeed utilize aluminum coils. The reason aluminum is favored for gutter systems is its ability to withstand wear, its lightweight composition, and its resistance to rust. Aluminum coils are frequently employed in the construction of seamless gutters, which boast several advantages over the more traditional sectional gutters. Custom-made on-site, seamless gutters guarantee a flawless fit for the specific measurements of a structure. This eliminates the necessity for seams, which are susceptible to leaks and require regular maintenance. Moreover, aluminum is malleable, making it easy to shape seamless gutters to accommodate a building's unique design. In summary, aluminum coils present a practical and efficient option for the creation of seamless gutters.

- Q: What kind of sensor is appropriate for aluminum coil thickness measurement?

- Thickness measurement can be divided into single-point and two-point thickness measurement, the principle of which is to measure thickness of aluminum coil through distance measure sensor. Single-point thickness measurement is to calculate the thickness by measuring the distance between the aluminum coils and then subtracting the distance with fiducial point. Double-point thickness measurement is to calculate the thickness by setting a proper distance between two sensors, putting the aluminum coil between them and measuring the distance and then subtracting the distance with initial distance, which is more accurate than single-point measurement. (Professional thickness measurement sensor is also based on single-point or two-point thickness measurement.) The distance measurement sensor can be divided into laser sensor, eddy current sensor and so on. The measuring range of laser sensor is larger than that of eddy current sensor, but less accurate. The While the accuracy of eddy current sensor is around 0.01%, and the measuring range is around several millimeters to more than ten millimeters.

- Q: What are the various applications and purposes for which aluminum coils are utilized?

- <p>Aluminum coils have a wide range of applications due to their lightweight, corrosion resistance, and malleability. They are commonly used in construction for roofing and siding, in the automotive industry for car parts and body panels, in the packaging industry for cans and foils, and in electrical applications for wiring and transformers. Aluminum coils are also used in the manufacturing of heat exchangers, cooking utensils, and various consumer products. Their versatility makes them an essential material in many industries.</p>

- Q: Can aluminum coils be used for outdoor applications?

- Yes, aluminum coils can be used for outdoor applications. Aluminum is a highly versatile and durable material that can withstand various weather conditions and temperatures. It is resistant to corrosion, making it suitable for outdoor environments where moisture and humidity are present. Additionally, aluminum coils are lightweight, which makes them easier to transport and install in outdoor settings. They are commonly used in outdoor applications such as roofing, siding, gutters, and HVAC systems. Overall, aluminum coils are a reliable choice for outdoor applications due to their strength, corrosion resistance, and longevity.

- Q: Are aluminum coils resistant to chemical exposure?

- Aluminum coils are widely recognized for their high resistance to chemical exposure. Aluminum itself possesses exceptional corrosion resistance properties, making it suitable for a variety of applications where it may encounter chemicals. The naturally occurring oxide layer on aluminum coil surfaces acts as a safeguard, preventing further corrosion and deterioration when exposed to numerous chemicals. Nevertheless, it is important to acknowledge that the chemical resistance of aluminum coils can vary depending on the specific type and concentration of the chemical involved. Certain aggressive chemicals or potent acids may still result in damage or corrosion over time. Therefore, it is always recommended to seek advice from experts or refer to specific chemical compatibility charts in order to determine the compatibility of aluminum coils with particular chemicals or environments.

- Q: Are there any limitations to the maximum coil length of aluminum coils?

- Yes, there are limitations to the maximum coil length of aluminum coils. The length of aluminum coils is typically restricted by factors such as the capabilities of manufacturing equipment, transportation constraints, and handling limitations. Additionally, longer coils are more prone to issues like coil sagging and deformation during storage or handling. Therefore, there is a practical limit to the maximum coil length that can be produced and effectively utilized in various industries.

Send your message to us

Aluminum Coil Goodman 0270a00983 - Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords