Aluminum Coil Anodizing Aca Corporation F/R Double Side Reflective Aluminum Foil Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

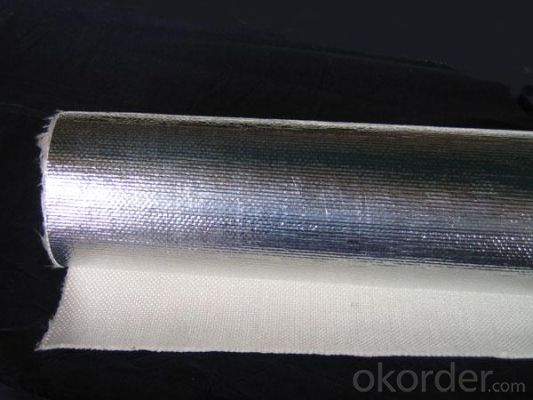

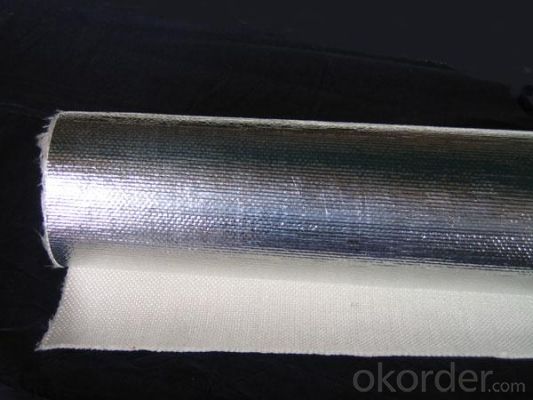

l Product Construction:

Composition | Description | Value (English) | Value (Metric) |

Foil | Aluminum | 0.28 mil | 7 micron |

Reinforcing - MD | Fiberglass | 2 / inch | 8 / 100mm |

Reinforcing - XD | Fiberglass | 3 / inch | 12 / 100mm |

Kraft | Natural | 49 lbs / 3000 ft2 | 80gsm |

Adhesive | Flame-Retardant Glue | ------ | ------ |

Foil | Aluminum | 0.28 mil | 7 micron |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden

pallets, waterproof paper and plastic coverage or or

as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance

payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

The business scope of CNBM covers from manufacturing and sales of a series of building materials to scientific research and design, import and export trade. In many of these fields, CNBM is playing the leading role.

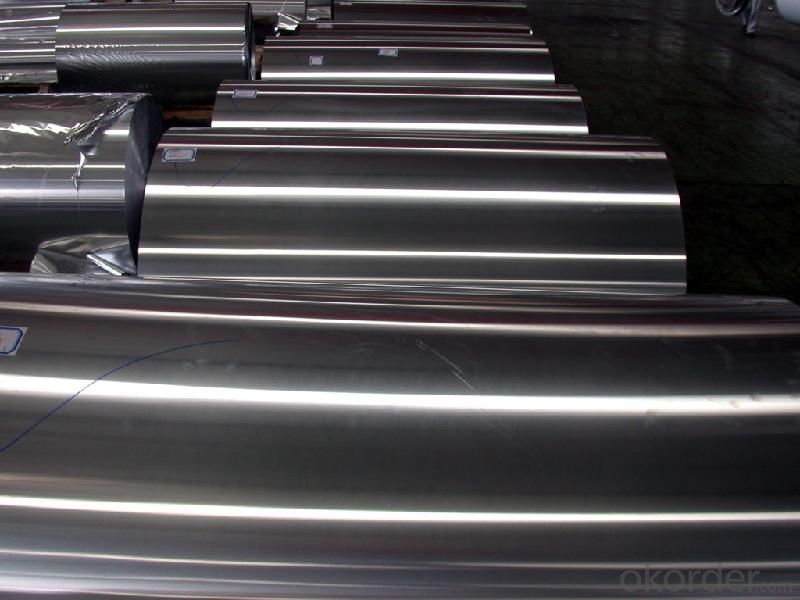

l Product Images

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 10 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Email:service@okorder.com

- Q: What will be the pros and cons of using each of these materials?One thing to keep in mind is that aluminum alloys are good conductors of electricity.

- One thing that you didn't mention is the size of the ladder. Depending on the size wood ladders are very heavy compared to aluminum and fiberglass. I prefer fiberglass ladders myself because they are sturdy, don't conduct electricity and the weight isn't too much if you have a large ladder.

- Q: How are aluminum coils used in the production of electronic devices?

- Aluminum coils are used in the production of electronic devices for various purposes such as providing electrical conductivity, heat dissipation, and electromagnetic shielding. These coils are typically used in components like transformers, inductors, and motors, where they help in the efficient transfer of electrical energy. Additionally, aluminum coils are often employed in cooling systems to dissipate heat generated by electronic components, ensuring their optimal performance and preventing overheating. Furthermore, aluminum coils can be utilized to create electromagnetic shields that protect sensitive electronic circuits from external electromagnetic interference, thus enhancing the overall reliability and functionality of electronic devices.

- Q: Are aluminum coils suitable for outdoor signage?

- Yes, aluminum coils are suitable for outdoor signage. Aluminum is a highly durable and weather-resistant material, making it perfect for outdoor applications. It is corrosion-resistant, meaning it can withstand exposure to various weather conditions such as rain, snow, and sunlight without deteriorating or rusting. Additionally, aluminum coils are lightweight and versatile, allowing for easy installation and customization. They can be easily cut, shaped, and painted to create eye-catching and long-lasting outdoor signage. Overall, aluminum coils are a popular choice for outdoor signage due to their durability, weather resistance, and aesthetic appeal.

- Q: Is aluminium a safe metal to put in ones mouth without any side effects?

- Heck yeah dude!! I love the taste of alluminum!

- Q: I need to lay down two 3 welds on some 1/8 aluminum but my welder is not set up for it. could i just out fit my welder with aluminum wire without buying the spool gun and get the same results? or maybe I should just get a welding shop to do it for me?

- - its easy to put a spool of Al wire in a mig welder, but that isn't the issue. as mentioned previously, the Al wire is very soft and may present problems feeding through the long feed tube. hence the design of the spool gun ... tube length = none ... no

- Q: How many companies have used aluminum coil?

- Too many. All the companies who make the aluminum products you have seen in daily life have used it. So it is hard to explain.

- Q: Can aluminum coils be used in the production of aluminum downspouts?

- Yes, aluminum coils can be used in the production of aluminum downspouts. Aluminum coils are typically made from high-quality aluminum alloy and are rolled into thin sheets. These coils can then be cut and formed into various shapes and sizes, including downspouts. Aluminum is a popular choice for downspouts due to its lightweight, durable, and corrosion-resistant properties. Additionally, aluminum coils can be easily manipulated and shaped to meet specific design requirements, making them suitable for manufacturing aluminum downspouts.

- Q: Are there any limitations on the welding or soldering of aluminum coils?

- Yes, there are limitations on welding or soldering aluminum coils. Aluminum has a relatively low melting point and high thermal conductivity, which can make it challenging to weld or solder effectively. The oxide layer on the surface of aluminum also makes it difficult to achieve a strong bond. Additionally, aluminum is prone to distortion and warping during the welding or soldering process. Therefore, special techniques and equipment, such as using specialized fluxes, inert gases, and proper pre-cleaning, are required to overcome these limitations and achieve successful welds or solder joints on aluminum coils.

- Q: What are the typical delivery methods for aluminum coils?

- Aluminum coils are transported using various delivery methods, which depend on the size and quantity of the coils. However, there are several commonly used methods in the industry. Trucks are one of the most frequently employed methods. Aluminum coils are typically transported on flatbed trucks, providing a secure and stable platform during transit. This method is suitable for both short and long-distance deliveries, and it allows for easy loading and unloading at the destination. Rail transportation is another popular method. It is often used when larger quantities of aluminum coils need to be delivered or when the distance is significant. Rail cars equipped with flatbeds or specialized coil cars are used to transport the coils safely and efficiently. This method is particularly advantageous for long-distance deliveries, as it is generally more cost-effective and eco-friendly compared to other modes of transportation. Sea transportation is sometimes used for delivering aluminum coils. This method is commonly employed for international shipments or when the coils need to be transported over long distances. Coils are typically packed into containers to ensure their safety and protection during the journey. Although shipping by sea allows for efficient transportation of large quantities of coils, it may take longer due to customs procedures and port handling. For smaller quantities of aluminum coils, air freight can be utilized. This method is often chosen when time is of the essence or for urgent shipments. Airplanes with cargo holds are used to transport the coils, ensuring their safe and expedited delivery. However, it is generally more expensive than other delivery methods, so it is typically reserved for time-sensitive or high-value shipments. In conclusion, the delivery methods for aluminum coils include trucks, rail, sea, and air. The appropriate method is selected based on factors such as size, quantity, distance, urgency, and cost considerations.

- Q: How are aluminum coils used in the production of battery enclosures?

- Aluminum coils are used in the production of battery enclosures as they provide a lightweight and durable material that can be easily molded and shaped to form the enclosure. The coils are typically processed and formed into specific shapes using a combination of heating, rolling, and cutting techniques. This allows for the creation of seamless and tightly sealed enclosures that can protect the batteries from external elements and provide efficient heat dissipation.

Send your message to us

Aluminum Coil Anodizing Aca Corporation F/R Double Side Reflective Aluminum Foil Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords