Aluminum Alloy Sheet for Construction and Semi Trailer Wall Application

- Loading Port:

- Shanghai

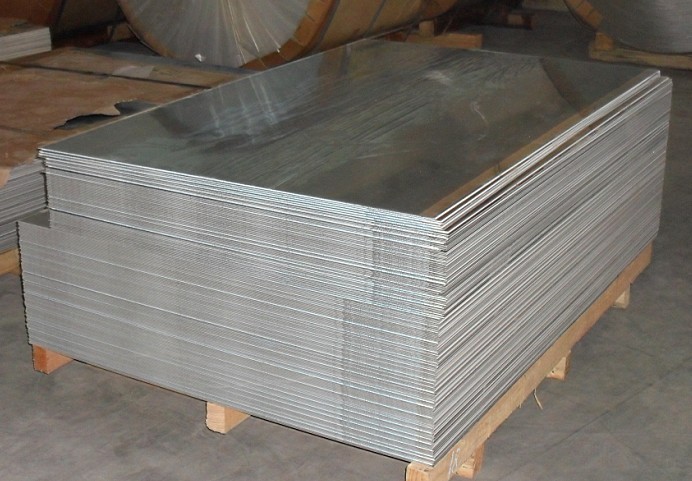

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

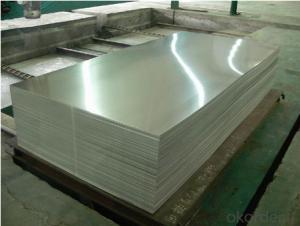

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

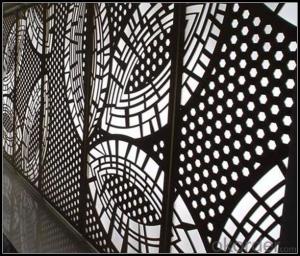

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Are aluminum sheets suitable for welding?

- Aluminum sheets are indeed suitable for welding, being widely used in various industries for their lightweight, corrosion resistance, and excellent thermal conductivity. However, welding aluminum presents challenges due to its high thermal conductivity and the formation of an oxide layer on its surface. Nevertheless, successful welding of aluminum sheets can be achieved with proper techniques and equipment. Tungsten Inert Gas (TIG) welding and Metal Inert Gas (MIG) welding are commonly employed for aluminum welding. These processes allow for precise heat control and the use of shielding gases to protect the weld pool from oxidation. In addition, achieving strong and reliable welds requires proper surface preparation, cleaning, and the use of specialized aluminum welding wires or rods. Overall, while specific techniques and equipment may be necessary, welding aluminum is feasible and widely practiced in various industries.

- Q: Can the aluminum sheets be used for manufacturing food packaging?

- Indeed, the utilization of aluminum sheets in the manufacturing of food packaging is feasible. Owing to its diverse characteristics, aluminum has become a favored option for food packaging. Its lightweight nature, resistance to corrosion, and exceptional heat conductivity are among the reasons for this preference. These attributes render it suitable for safeguarding the freshness and quality of food items. Moreover, aluminum possesses impermeability to light, moisture, and oxygen, thereby aiding in the extension of the shelf life of food products. Furthermore, the malleability of aluminum sheets enables them to be effortlessly molded into various shapes and sizes, thus facilitating tailored packaging solutions. In essence, the food packaging industry frequently relies on aluminum sheets due to their adaptability, durability, and their ability to ensure the safety and integrity of food items.

- Q: What is aluminium plate L2-Y2?

- L2 is the old number, the new brand corresponds to 1060, and the same Y2 is also the old number to indicate the state of the heat treatment method, the new method of expression is H24, which means semi hard state. Ji'nan Hongda Aluminium Industry Co., Ltd.

- Q: This question asks about the various color options available for aluminum sheets.

- <p>Aluminum sheets are available in a wide range of colors to suit various applications and aesthetic preferences. Common colors include silver (anodized), white, black, and clear (natural). Beyond these, there are also options for colors like red, blue, green, and yellow. Some manufacturers offer custom color matching services for specific projects. Additionally, aluminum sheets can be coated with various finishes such as matte, gloss, or textured, further expanding the color and appearance options. It's important to check with specific suppliers for their available color range as it can vary.</p>

- Q: Can aluminum sheets be used for reflective purposes?

- Yes, aluminum sheets can be used for reflective purposes due to their high reflectivity and low absorption of light.

- Q: Are aluminum sheets suitable for food contact applications?

- Yes, aluminum sheets are suitable for food contact applications. Aluminum is a widely used material in the food industry due to its various beneficial properties. It is non-toxic, non-reactive, and corrosion-resistant, making it safe to use with food. Aluminum sheets can be easily formed into different shapes and sizes, making them suitable for a wide range of food packaging and cooking applications. Additionally, aluminum has excellent thermal conductivity, which allows for efficient heat transfer during cooking or baking. It is also impermeable to light, moisture, and oxygen, providing a protective barrier to maintain the freshness and quality of food. Overall, aluminum sheets are a popular choice for food contact applications due to their safety, versatility, and durability.

- Q: Can aluminum sheets be bent into complex shapes?

- Yes, aluminum sheets can be bent into complex shapes. Aluminum is a highly malleable and ductile metal, which means it can be easily shaped and formed without breaking or cracking. This makes it ideal for creating intricate and complex shapes in various industries such as automotive, aerospace, construction, and more. The process of bending aluminum sheets into complex shapes typically involves using specialized equipment such as press brakes or rollers to apply force and form the desired shape. With the right techniques and equipment, aluminum sheets can be bent into curves, angles, and even intricate patterns with precision and accuracy.

- Q: This question asks for methods to maintain and repair aluminum sheets once they have been installed.

- <p>To maintain and repair aluminum sheets after installation, follow these steps: Regularly clean the surface with a soft cloth and mild detergent to remove dirt and grime. Avoid abrasive materials that can scratch the surface. For minor scratches or dents, use aluminum filler or touch-up paint that matches the sheet's color. Apply the filler or paint carefully, following the manufacturer's instructions. For more severe damage, consider hiring a professional to assess and repair the damage to ensure structural integrity. Always check for any signs of corrosion and address them promptly to prevent further damage. Regular maintenance will prolong the life of aluminum sheets and keep them looking their best.</p>

- Q: Can aluminum sheets be used for air ducts?

- Yes, aluminum sheets can be used for air ducts. Aluminum is a commonly used material for air ducts due to its lightweight, durable, and corrosion-resistant properties. It is also easy to work with and can be easily shaped and formed to fit various duct designs.

- Q: Are the aluminum sheets suitable for manufacturing chemical storage cabinets?

- Indeed, chemical storage cabinets can be manufactured with aluminum sheets. Aluminum, being a robust and long-lasting material, exhibits corrosion resistance, thus making it an excellent choice for safeguarding chemicals. Its lightweight nature renders transportation and installation more convenient. Moreover, aluminum remains non-reactive with the majority of chemicals, thereby ensuring the safety of stored substances. In summary, the utilization of aluminum sheets offers a dependable and effective solution for the production of chemical storage cabinets.

Send your message to us

Aluminum Alloy Sheet for Construction and Semi Trailer Wall Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords