Aluminum Sheets in Arizona - Aluminium Profile with Sand Blasting Treatment SA6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Profile with Sand Blasting Treatment SA6 Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of theAluminium Profile with Sand Blasting Treatment SA6:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

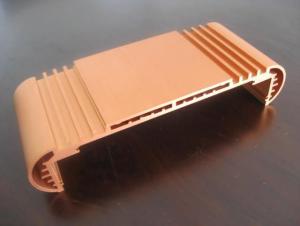

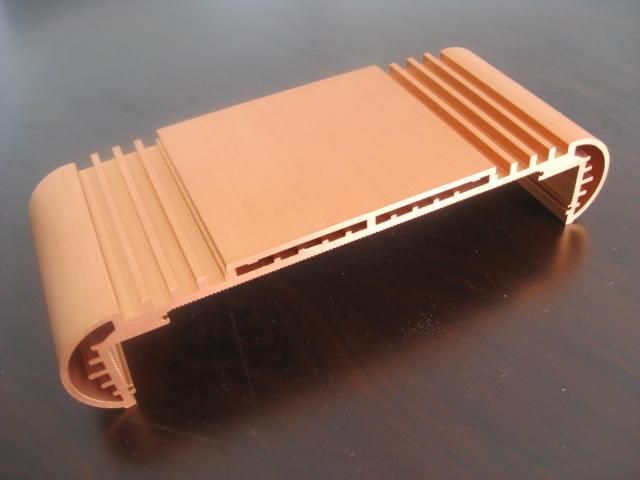

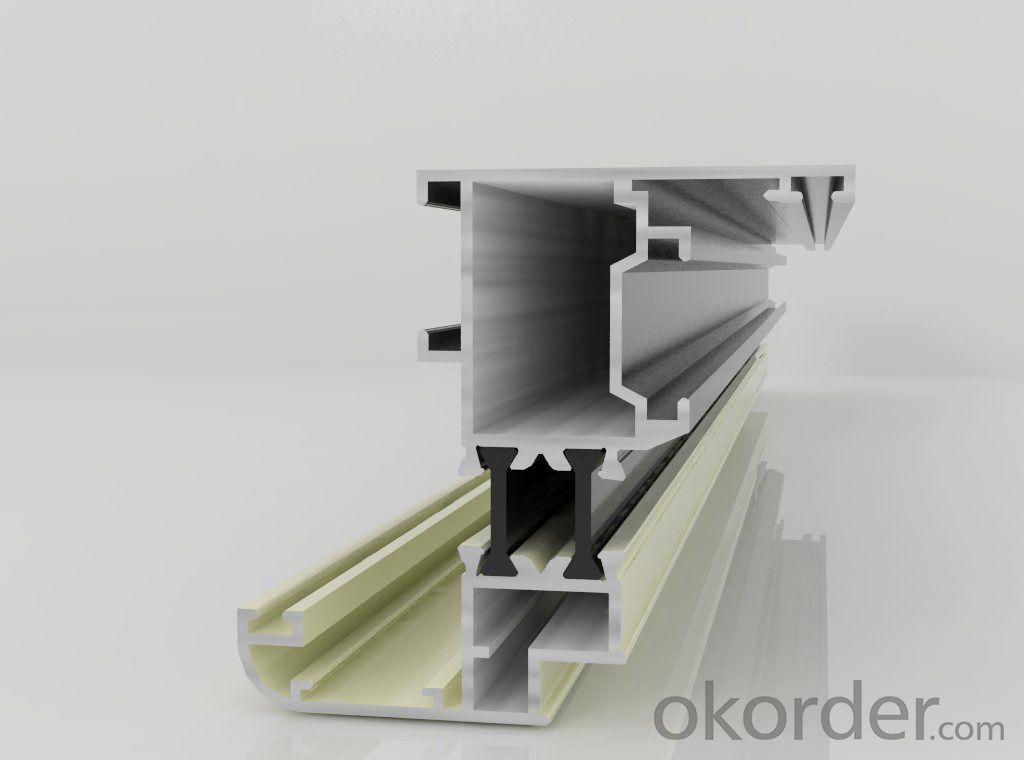

3.Aluminium Profile with Sand Blasting Treatment SA6 Images:

4.Aluminium Profile with Sand Blasting Treatment SA6 Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: This question asks for a list of various coatings that can be applied to aluminum sheets for different purposes.

- <p>Aluminum sheets can be coated with a variety of materials to enhance their properties such as durability, appearance, and corrosion resistance. Some common types of coatings include: 1. Anodizing: Creates a protective oxide layer on the aluminum surface. 2. Powder Coating: A dry coating that is electrostatically applied and then cured at high temperatures. 3. PVDF (Polyvinylidene Fluoride) Coating: Known for its excellent resistance to UV, chemicals, and weathering. 4. Epoxy Coating: Provides a hard, durable finish that is resistant to chemicals and corrosion. 5. Polyester Coating: Offers good adhesion and is often used for outdoor applications. 6. Fluorocarbon Coating: Provides a high level of durability and resistance to weathering. 7. Ceramic Coating: A newer type of coating that offers excellent heat resistance and a smooth finish. These coatings are chosen based on the specific requirements of the application, such as architectural, automotive, or aerospace uses.</p>

- Q: I have no idea, and I can't figure this out, and neither can my aunt and she's super smart. It's this project that's due on Monday, and if I can't get it turned in, then I get detention and a failing lab grade. The only information I have is it's $2.96 for a roll of aluminum, it contains 2.96 square meters, and it weighs .995 grams...

- say it's a trick question, because it there is no denotational value for a single aluminum atom :/

- Q: What are the advantages of using aluminum sheets in the packaging industry?

- Aluminum sheets have numerous benefits in the packaging industry. To begin with, their lightweight composition makes them ideal for packaging purposes. Unlike steel or glass, aluminum is much lighter, making it easier to handle and transport. This weight advantage also reduces shipping costs, as less fuel is needed for transportation. In addition, aluminum sheets provide excellent barrier properties. They effectively block out oxygen, moisture, and light, all of which can compromise the quality and freshness of packaged goods. This barrier extends the shelf life of products, ensuring they reach consumers in optimal condition. Moreover, aluminum sheets are highly durable and resistant to corrosion. This durability guarantees that packaged items remain protected, even in challenging environmental conditions. They are also resistant to temperature fluctuations, maintaining the integrity of the packaging material without warping or deforming. Furthermore, aluminum is a highly recyclable material. Its use in the packaging industry promotes sustainability and reduces the carbon footprint. Aluminum packaging is easily recyclable and reusable, minimizing the need for new materials and reducing waste. Additionally, aluminum sheets offer versatility in terms of design and customization. They can be easily molded and shaped into various packaging formats, including cans, trays, foils, and pouches. This flexibility enables packaging manufacturers to create innovative and visually appealing solutions that cater to the unique needs and preferences of different industries and consumers. Overall, the advantages of using aluminum sheets in the packaging industry encompass their lightweight nature, excellent barrier properties, durability, recyclability, and versatility. These benefits establish aluminum sheets as the preferred choice for packaging manufacturers, ensuring the protection, preservation, and attractiveness of packaged products.

- Q: How do you cut aluminum sheets?

- To cut aluminum sheets, you can use various methods depending on the thickness and size of the sheet. Here are a few common methods: 1. Hand shears: For thin aluminum sheets, hand shears can be effective. These are handheld tools with sharp blades that can cut through the sheet by applying manual force. 2. Power shears: For thicker aluminum sheets, power shears are a better option. These electric or pneumatic tools have powerful blades that can cut through the material with ease. They are especially useful for straight cuts. 3. Jigsaw: A jigsaw with a metal-cutting blade can be used to cut aluminum sheets, especially when you need to make curved or irregular cuts. Make sure to use a blade specifically designed for cutting metal. 4. Circular saw: A circular saw with a carbide-tipped blade can also be used to cut aluminum sheets. This method is suitable for straight cuts and requires the sheet to be clamped securely to avoid vibrations during cutting. 5. CNC cutting: Computer Numerical Control (CNC) machines can be used to accurately cut aluminum sheets into precise shapes and sizes. These machines use computer programs to control the cutting process, making them ideal for complex or repetitive cuts. Before cutting aluminum sheets, ensure you wear appropriate safety gear, such as gloves and safety glasses, to protect yourself from any sharp edges or metal shavings. It is also advisable to secure the sheet firmly in place using clamps or a vise to prevent movement during cutting.

- Q: Aluminum knowledge. What is the model 3003 H24? What does H mean?

- H: work hardening state.(1) Hxx state:H1 * - hot rolling, Zhang Liqiang; H2 * - continuous casting and rolling, Zhang Liqiang, part of the toughening; H3 * - after stress treatment, stable performance; H4 * - after paint or coating; H x 2 - 25% x 4 - H hardness; hardness 50% processing; H * 6 - 75% hardness; H * 8 - 90 more than the hardness.(2) Hxxx state:H111: suitable for the final annealing, but also a proper amount of work hardening, but the degree of hardening is not as good as the H11 state of the product.H112: for hot forming products, the mechanical properties of the condition are specified.H116: made for magnesium content more than 4% 5 * * * alloy products. These products have specified mechanical properties and anti stripping corrosion resistance requirements.

- Q: Are aluminum sheets suitable for roofing?

- Indeed, aluminum sheets prove to be a fitting choice for roofing purposes. Renowned for its lightweight nature, durability, and corrosion resistance, aluminum stands out as a favored material in the roofing industry. Moreover, its non-combustible properties render it a safer alternative. The ease of installation and maintenance further add to its appeal, as do its ability to withstand adverse weather conditions like heavy rain, snow, and wind. Notably, aluminum also earns accolades as an environmentally conscious option, boasting 100% recyclability. In summary, aluminum sheets offer a trustworthy and enduring roofing solution for both residential and commercial edifices.

- Q: Can aluminum sheets be used in automotive applications?

- Yes, aluminum sheets can be used in automotive applications. Aluminum is lightweight, corrosion-resistant, and has good strength-to-weight ratio, making it an ideal material for manufacturing automotive components such as body panels, engine parts, and structural components.

- Q: Can aluminum sheets be anodized?

- Yes, aluminum sheets can be anodized. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum. This layer enhances the metal's corrosion resistance, durability, and appearance. Anodizing is commonly used in various industries such as automotive, aerospace, and construction to provide a protective coating and improve the aesthetics of aluminum sheets. The process involves immersing the aluminum sheet in an acid electrolyte solution and passing an electric current through it, causing oxygen ions to bond with the aluminum atoms and form the oxide layer. This layer can be further enhanced with the addition of dyes or pigments to create different colors and finishes. Overall, anodizing is a versatile and effective method for treating aluminum sheets.

- Q: Can 101 aluminum sheets be welded?

- Absolutely, welding is indeed possible with 101 aluminum sheets. The 101 aluminum alloy, renowned for its superb weldability, is extensively employed in welding applications. However, it is crucial to emphasize the significance of employing appropriate welding techniques and equipment to achieve a triumphant weld.

- Q: How does aluminum sheet perform in extreme temperatures?

- Aluminum sheet performs well in extreme temperatures as it has a high melting point of 660°C (1220°F) and exhibits excellent thermal conductivity. It can withstand both hot and cold temperatures without significant deformation or structural damage, making it suitable for various applications in extreme environments.

Send your message to us

Aluminum Sheets in Arizona - Aluminium Profile with Sand Blasting Treatment SA6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords