Aluminum Sheets for Racing:Best Price Aluminium Plate and Sheet in Warehouse

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

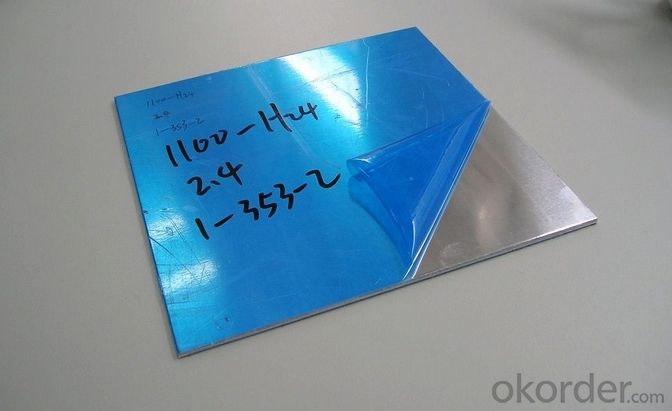

1.Structure of Product Description

aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series,7000series,8000 series,etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, etc.

The temper is include H14, H22, H24, H44,H112,O, H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm, 1250mm*2500mm, at random sizes,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 5 tons/each size.

How many tons did you export in one year

Japan, Vietnam, Singapore,Turkey,Fiji, etc.

What is your mainly products?

---Normally they are aluminum sheet,mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Are aluminum sheets suitable for welding?

- Yes, aluminum sheets are suitable for welding. Aluminum is a widely used material in various industries due to its lightweight, corrosion resistance, and excellent thermal conductivity. However, welding aluminum can be more challenging compared to other metals due to its high thermal conductivity and the formation of an oxide layer on its surface. Nevertheless, with the appropriate welding techniques and equipment, aluminum sheets can be successfully welded. Specialized welding processes such as Tungsten Inert Gas (TIG) welding or Metal Inert Gas (MIG) welding are commonly used for aluminum welding. These processes allow for precise control of heat input and the use of suitable shielding gases to protect the weld pool from oxidation. Additionally, proper surface preparation, cleaning, and the use of specialized aluminum welding wires or rods are essential for achieving strong and reliable welds. Overall, while welding aluminum may require specific techniques and equipment, it is definitely feasible and commonly practiced in various industries.

- Q: Can aluminum sheets be used for cookware?

- Cookware can indeed utilize aluminum sheets. Due to its exceptional heat conductivity and lightweight nature, aluminum remains a favored material for cookware. In the construction of cooking utensils like pots, pans, and baking sheets, aluminum sheets frequently serve as the base or core material. To enhance durability and user-friendliness, these sheets are often coated with a nonstick or ceramic layer. Nonetheless, it is crucial to recognize that pure aluminum can react with certain acidic or alkaline foods, resulting in a metallic taste or discoloration. To prevent such occurrences, most aluminum cookware is anodized or coated, establishing a barrier between the food and the aluminum surface. All in all, aluminum sheets prove to be an adaptable and widely employed option for cookware in both professional and domestic kitchens.

- Q: Which explains aluminum's resistance to corrosion? Any aluminum oxide that forms readily falls off the metal and exposes the corrosion-resistant metal. The aluminum oxide that forms adheres to the metal surface. The reduction half-reaction Al3+(aq) + 3e- ---gt; Al(s) occurs readily. The standard reduction potential for the Al3+/Al half-reaction is above the standard reduction potential for the O2/H2O half-reaction.

- the fourth one is correct the fourth statement tells us that aluminium is more reactive(it has higher electrode potential) so it cannot be displaced by 02/H20 which has lower electrode potential (which means it is less reactive)so less reactive cannot displace more reactive hope so it will help

- Q: Can aluminum sheets be used for heat dissipation?

- Yes, aluminum sheets can be used for heat dissipation. Aluminum is known for its excellent thermal conductivity, which allows it to efficiently transfer heat away from a source. This makes it a popular choice for heat sinks and heat exchangers in various industries. Aluminum sheets can be shaped and formed into different configurations to maximize surface area and enhance heat dissipation. The lightweight and corrosion-resistant nature of aluminum also make it a preferred material for heat dissipation applications.

- Q: How does aluminum sheet compare to other metals in terms of weight?

- Aluminum sheet is exceptionally lightweight compared to most other metals. It has a lower density, making it a popular choice for applications where weight reduction is a priority.

- Q: Are aluminum sheets suitable for food processing conveyor systems?

- Yes, aluminum sheets are suitable for food processing conveyor systems. Aluminum is a lightweight and durable material that is resistant to corrosion and can withstand extreme temperatures. It is also non-toxic and does not react with food, making it a safe choice for conveying food products. Additionally, aluminum sheets are easy to clean and maintain, making them an ideal option for food processing conveyor systems.

- Q: What is the weight of aluminum sheets per square foot?

- The weight per square foot of aluminum sheets may differ depending on the sheet's thickness or gauge. Typically, a 1/8 inch thick aluminum sheet weighs approximately 1.9 pounds per square foot. Nevertheless, thinner sheets tend to be lighter, whereas thicker sheets can be heavier. It is crucial to take into account the precise thickness of the aluminum sheet when calculating its weight per square foot.

- Q: Can aluminum sheets be used for architectural sunshades?

- Yes, aluminum sheets can be used for architectural sunshades. Aluminum is a lightweight and durable material that is commonly used in construction and architecture. It can be easily shaped and manipulated to create various designs and configurations for sunshades, providing protection from sunlight and enhancing the aesthetic appeal of buildings. Additionally, aluminum is resistant to corrosion, making it suitable for outdoor applications and ensuring the longevity of sunshade structures.

- Q: Are aluminum sheets suitable for packaging applications?

- Yes, aluminum sheets are highly suitable for packaging applications due to their lightweight, corrosion-resistant, and excellent barrier properties. They can effectively protect products from moisture, light, and oxygen, ensuring longer shelf life and freshness. Additionally, aluminum sheets are easily formable, making them suitable for various packaging formats like cans, foils, and pouches.

- Q: I am engaged in line cutting, because the cut aluminum plate conductive block wear more fierce, molybdenum wire is often broken card, I do not know that heroes have unique skills, say, we share. Thanks.

- The contact position between the conductive block and the electrode wire is often changed

Send your message to us

Aluminum Sheets for Racing:Best Price Aluminium Plate and Sheet in Warehouse

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords