6061 Aluminum Embossed Sheet for Roofing Application - 5-Pack

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

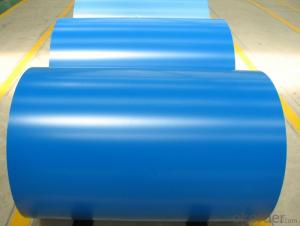

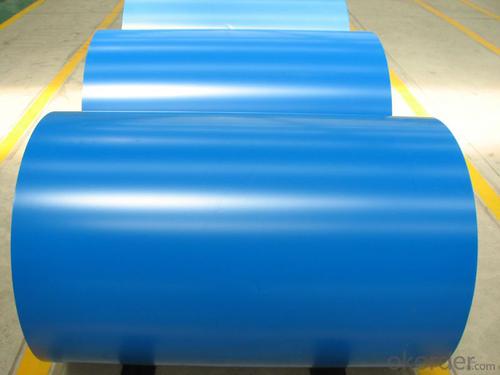

Structure of Aluminium Embossed Sheet for Roofing Application Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Embossed Sheet for Roofing Application:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

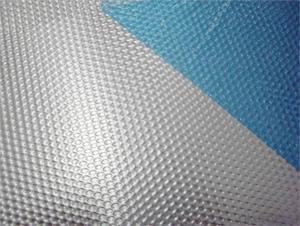

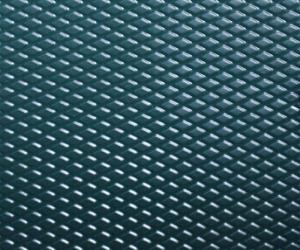

Images of the Aluminium Embossed Sheet for Roofing Application:

Aluminium Embossed Sheet for Roofing Application Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Prepaited Coil:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What kind of pattern aluminium plate has?

- Aluminum alloy decorative plate: Aluminum shallow pattern boardThe shallow pattern board of aluminum alloy is one of the excellent building decoration materials. It is exquisite pattern, color appearance, has the common advantages of ordinary aluminum plate, the stiffness is increased by 20%, anti fouling, anti scratch, anti abrasion ability has been improved, especially the increase of three-dimensional pattern and beautiful color, make the building more brightly.Aluminium alloy decorative panels: aluminium and aluminium alloy corrugated platesAluminum and Aluminum Alloy corrugated plate is widely used in the world of decorative materials, it is mainly used for wall decoration, can also be used for roofing, surface chemical treatment can have a variety of colors, good decorative effect, but also has a strong reflection of the light, very durable, the service life of up to 20 years. And it has a variety of colors, both decorative effect, but also has a strong ability to reflect sunlight. It can resist fire, moisture and corrosion.

- Q: What are the surface treatment requirements for aluminum sheets in the food industry?

- In the food industry, aluminum sheets used for food packaging and handling must undergo specific surface treatments to meet hygiene and safety standards. The surface treatment requirements for aluminum sheets in the food industry typically involve processes like cleaning, degreasing, and anodizing. These treatments remove any dirt, oils, or contaminants, and create a protective layer on the aluminum surface to prevent corrosion and ensure the sheets are safe for food contact. Additionally, the surface treatments may also include specific coatings or laminations to enhance the barrier properties and maintain the quality and freshness of the food products.

- Q: How does the surface treatment of aluminum sheet affect its appearance?

- The appearance of aluminum sheet is greatly influenced by its surface treatment. Natural aluminum has a shiny and reflective surface, which can be improved or modified through different surface treatments. One popular surface treatment for aluminum sheet is anodizing, which involves the creation of a protective oxide layer on the surface through an electrochemical process. This treatment offers a wide range of colors and finishes, ranging from vibrant and opaque to translucent and metallic. Anodized aluminum sheets have a sleek and modern look, making them commonly used in architectural and decorative applications. Another option for surface treatment is painting or powder coating. These processes involve applying a layer of paint or powder onto the surface of the aluminum sheet. This treatment allows for customization in terms of color, texture, and finish. Painted or powder-coated aluminum sheets can have a smooth and glossy appearance or a textured and matte finish, depending on the desired outcome. This treatment is frequently utilized in industries like automotive, aerospace, and construction, where aesthetics and durability are important. Additionally, aluminum sheets can undergo mechanical surface treatments like brushing or polishing. Brushing involves creating parallel lines on the sheet's surface using abrasive pads, resulting in a brushed or satin finish. This treatment gives aluminum sheets a contemporary and industrial look. On the other hand, polishing involves buffing the surface to a high gloss and mirror-like finish. This treatment is often used for decorative purposes, such as in the production of jewelry or household items. In conclusion, the surface treatment of aluminum sheet plays a crucial role in determining its appearance. Whether it is anodizing, painting, powder coating, brushing, or polishing, each treatment offers a distinct visual effect that can enhance the aesthetic appeal of the aluminum sheet for specific applications and industries.

- Q: How do aluminum plates open holes?

- The opening of the aluminum plate is a relatively simple process,You can do that with a micro electric device like an electric drill or a grooving machine

- Q: What is the thickness range available for 101 aluminum sheets?

- The thickness range available for 101 aluminum sheets typically varies from 0.016 inches (0.4 mm) to 0.25 inches (6.35 mm).

- Q: Can aluminum sheets be used for aircraft manufacturing?

- Yes, aluminum sheets are commonly used for aircraft manufacturing. Aluminum is a lightweight and corrosion-resistant material, making it an ideal choice for constructing various components of an aircraft. It is strong enough to withstand the stresses and strains experienced during flight, while also being malleable enough to be formed into various shapes and sizes. Additionally, aluminum sheets can be easily joined together using various welding techniques, allowing for efficient and effective assembly of aircraft structures. Overall, the use of aluminum sheets in aircraft manufacturing helps to ensure a balance between strength, weight, and durability, making it a preferred material in the aerospace industry.

- Q: i added aluminum sulfate to the soil from the bag with out mixing it with water and my hydrangeas look very sad. It burned them i guess... What is best thing to do to take some of it out or all if i can? will adding large amounts of water to the soil help it clear or will it make it worse? please before they die!!!10points!!!

- how much did you add i mix it with the soil for my hydrangeas and never have a problem.. blend it into the soil around the hydrangeas the burning you see may be related to something other than the aluminum sulfate

- Q: Can aluminum sheets be roll-formed?

- Yes, aluminum sheets can be roll-formed. Roll forming is a process in which a continuous strip of metal, in this case, aluminum, is fed through a series of rollers to gradually shape it into a desired profile or shape. Aluminum is an ideal material for roll forming due to its malleability and ductility, allowing it to be easily bent, curved, and formed into various shapes. It is commonly used in industries such as construction, automotive, and aerospace for applications that require lightweight yet durable components.

- Q: Can aluminum sheets be used in aerospace industries?

- Yes, aluminum sheets can be used in aerospace industries. Aluminum is commonly used in the aerospace industry due to its lightweight, high strength-to-weight ratio, and corrosion resistance properties. It is used for various applications such as aircraft structures, wings, fuselages, and skins.

- Q: project on aluminum and i cant think of a good/funny slogan for it! HELP! i have already seen the other possibilities on google, try to be unique, and creative! but if you cant just answer the flipping question PLZ!

- Once worth more than Gold Aluminum: It's the flipping answer If government could read your thoughts, you can always wear aluminum head gear. Aluminum - The super wealthy recycle it. Lucky Element 13 - Aluminum Say no to radiation from machines; Say yes to Aluminum Nothing Says Christmas like Shinny Metallic Reynolds Gift Wrapping Aluminum - it's worth more money than slogans because I get those for free over the Internet

Send your message to us

6061 Aluminum Embossed Sheet for Roofing Application - 5-Pack

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords