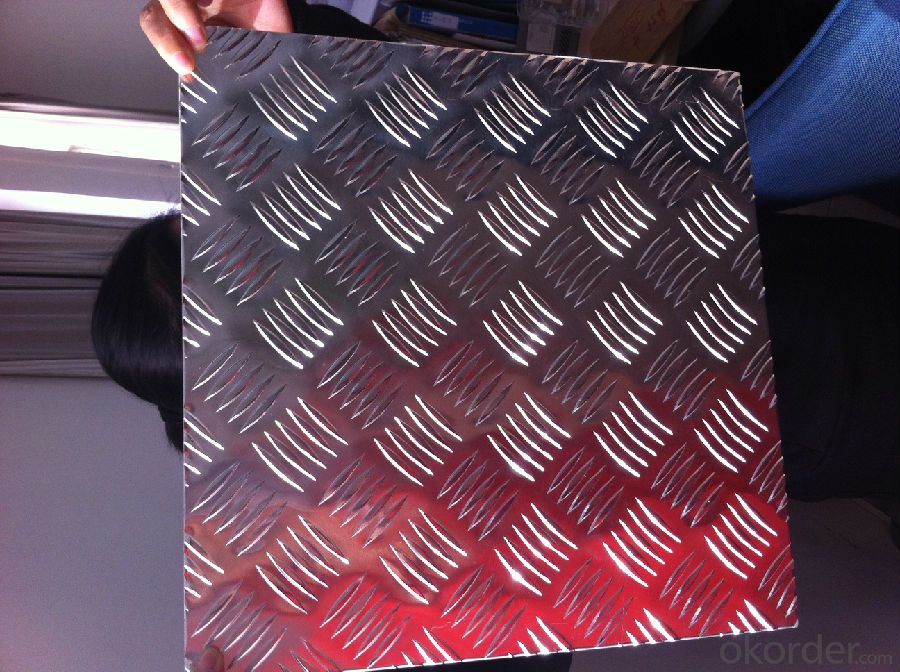

Aluminum Sheets South Carolina - Aluminium Checkered and Mirror Sheet in Our Warehouse with Better Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

CNB, INTERNATIONAL CORPORATION'S Aluminum checkered sheet and mirror sheet and best-selling price with shortest delivery time, sheet is widely used in the field of industrial construction field and decoration field, etc.

There are alloy nubmer: 6000 series,7000series, 8000 series, etc. The detailed grade are as 3003, 5052,5754,6061,6063,8011, etc.

The temper is include O, H111, H112, H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1219mm*2438mm,500MM*500MM,1000*1000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 500mm to 2500mm, etc.

What is the length range:

---It is from ur products yet?

---Normally it is around 2 tons/each size.

How many tons did you export in one year?

---Normally it is around 8900 tons totally.

Where is your client from?

---Normally it is from Pakistan,Saudi Arabia, BANGLADESH,PAKISTAN,FIJI, England,Turkey,etc.

What is big-5-bar aluminium checkered sheet,small-5-bar aluminium checkered sheet,mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: How do 101 aluminum sheets compare in terms of strength and durability?

- 101 aluminum sheets are known for their excellent strength and durability properties. They offer a high level of resistance to corrosion, making them suitable for various applications in industries such as automotive, construction, and aerospace. Additionally, their strength-to-weight ratio is impressive, allowing for efficient use in structures where weight reduction is essential. Overall, 101 aluminum sheets are considered strong and durable materials with a wide range of practical uses.

- Q: How do you prevent galvanic corrosion when using aluminum sheets with concrete?

- To prevent galvanic corrosion when using aluminum sheets with concrete, several preventive measures can be taken: 1. Barrier Coating: Apply a barrier coating or paint on the aluminum sheets to separate them from the concrete. This coating acts as a protective layer, preventing direct contact between the aluminum and the concrete, thereby reducing the chances of galvanic corrosion. 2. Insulation: Introduce an insulating material between the aluminum sheets and the concrete. This material can be a non-conductive plastic or rubber sheet that effectively isolates the aluminum from the concrete, minimizing the risk of galvanic corrosion. 3. Surface Treatment: Apply a corrosion-resistant treatment to the aluminum sheets. Anodizing is a common surface treatment method that creates a protective oxide layer on the aluminum surface, making it more resistant to corrosion when in contact with concrete. 4. Use Dissimilar Metals: Avoid using dissimilar metals in contact with aluminum sheets and concrete. When dissimilar metals, such as steel or iron, come into contact with aluminum in the presence of moisture, galvanic corrosion is more likely to occur. Therefore, it is best to use aluminum fasteners or supports when working with aluminum sheets and concrete. 5. Proper Drainage: Ensure proper drainage in areas where aluminum sheets are in contact with concrete. Accumulation of water or moisture can accelerate galvanic corrosion. By providing adequate drainage, you can minimize the amount of moisture that comes into contact with the aluminum, reducing the risk of corrosion. 6. Regular Maintenance: Regularly inspect and maintain the aluminum sheets and their protective measures. If any damage or deterioration is observed, promptly repair or replace the barrier coatings, insulation, or surface treatments to ensure continued protection against galvanic corrosion. By implementing these preventive measures, you can significantly reduce the risk of galvanic corrosion when using aluminum sheets with concrete, prolonging the lifespan and integrity of the aluminum and the concrete structures.

- Q: What are the dimensions and thickness options for aluminum sheets?

- The dimensions and thickness options for aluminum sheets vary depending on the specific requirements and applications. Aluminum sheets are available in a wide range of sizes and thicknesses to suit different needs. In terms of dimensions, aluminum sheets can be found in various widths and lengths, typically ranging from 36 inches to 72 inches in width and 96 inches to 144 inches in length. These dimensions can, however, vary depending on the supplier and specific product. The thickness options for aluminum sheets also vary. The thickness is typically measured in gauge, with lower gauge numbers indicating thicker sheets. Aluminum sheets are available in various gauges, ranging from 0.006 inches (very thin) to 0.5 inches (thicker) or even thicker for specialized applications. It's important to note that specific dimensions and thickness options may vary depending on the supplier and the specific grade of aluminum being used. It is always recommended to consult with a supplier or manufacturer for precise information on available dimensions and thickness options for aluminum sheets.

- Q: What does 1060h/24 mean in aluminium alloy?

- In two the number of Arabia aluminum has no special meaning, is only used to identify the different alloys in the same group, said its second modifications.Four, H24 H said the work hardening of the state, and some do not have H but T said it is heat treatment.24 machining process control hardness and other properties, in addition to 24 and 12, 14, 16, 18, 22, 26, 34, 36 and so on, usually at the end of 4 is a semi hard state.1060O, 1060-H22, 1060-H24, 1060-H18 state is arranged from soft to hard.

- Q: What is the cost of aluminum sheets?

- The cost of aluminum sheets can vary depending on various factors such as the thickness, size, and grade of the aluminum. Additionally, market conditions and supplier pricing policies can also influence the cost. It is recommended to contact local suppliers or search online to get the most accurate and up-to-date pricing information for aluminum sheets.

- Q: I'm about to fix the aluminum wiring in my house using Alumiconn connection, so I know that every outlet and switch plate need to be done, do the light fixtures need to be done as well? And also does anything need to be done with the main circuit breaker?

- Normally, the houses are ceiling with copper wires on the walls instead of aluminum. Because of safe secure and also cost effective. Better to replace all the things.

- Q: I saw a guy on ebay take a washed out paint can fill it full of lighted charcoal bricks and a tin can in the middle. He was melting aluminum cans in there then pured it into a mold. Does this really work and does anyone have any good ideas on how else to do this?

- Aluminum alloys melt at around 1200 degrees, aluminum cans maybe somewhat lower, but I doubt a tin can would hold up long enough to melt much aluminum, and you would need to be very careful, any moisture in your mold will cause the aluminum to literally explode back into your face. I am not saying it couldn't be done, but you really would need lots of safety equipment before trying it.

- Q: Can aluminum sheets be used in aerospace industry?

- Yes, aluminum sheets are commonly used in the aerospace industry. Aluminum has several properties that make it an ideal material for aerospace applications. Firstly, it is lightweight, which is crucial for aircraft and spacecraft as it helps reduce fuel consumption and increase payload capacity. Secondly, aluminum has excellent strength-to-weight ratio, providing the necessary structural integrity for aerospace components. Additionally, aluminum is highly corrosion-resistant, ensuring durability and longevity in harsh environments. It also has good thermal conductivity, making it suitable for heat dissipation in aerospace systems. Furthermore, aluminum is easily formable, allowing for complex shapes and structures to be manufactured. Overall, the versatility, strength, lightness, and corrosion resistance of aluminum make it a preferred material in the aerospace industry for various applications such as aircraft frames, fuselage panels, wings, and engine components.

- Q: What are the different methods of surface passivation for aluminum sheets?

- There are several different methods of surface passivation for aluminum sheets, each with its own advantages and applications. Some of the commonly used methods include anodizing, chromate conversion coating, and organic coating. 1. Anodizing: Anodizing is a widely used method that involves creating a thick protective oxide layer on the surface of the aluminum sheet. This is achieved by immersing the sheet in an electrolyte solution and passing a current through it. Anodizing provides excellent corrosion resistance, improves the surface hardness, and allows for various color options through dyeing. It is commonly used in architectural and decorative applications. 2. Chromate conversion coating: Chromate conversion coating, also known as chemical conversion coating or chromating, involves treating the aluminum surface with a solution containing chromate compounds. This method provides a thin, protective layer that improves corrosion resistance and enhances paint adhesion. It is widely used in aerospace, automotive, and electronics industries. 3. Organic coating: Organic coating refers to the application of a protective layer of organic material, such as paint or powder coating, onto the aluminum surface. This method provides exceptional corrosion resistance and can also offer aesthetic options. Organic coating is commonly used in industries where the aluminum sheets are exposed to harsh environments or require specific colors or finishes. 4. Plasma electrolytic oxidation (PEO): PEO is a relatively newer method that involves immersing the aluminum sheet in an electrolyte solution and passing high-voltage current through it. This process leads to the formation of a ceramic-like oxide layer on the surface, which enhances corrosion resistance, hardness, and wear resistance. PEO is commonly used in applications requiring high-performance coatings, such as aerospace and automotive industries. 5. Passivation with acids or chemicals: Passivation using acids or chemicals involves treating the aluminum surface with a solution that removes impurities and forms a protective layer. This method helps in reducing the reactivity of the surface and enhances corrosion resistance. It is commonly used in industrial applications where aluminum sheets are exposed to harsh chemicals or environments. Overall, the choice of surface passivation method for aluminum sheets depends on the specific requirements of the application, such as corrosion resistance, aesthetics, hardness, and environmental factors. It is important to consider factors such as cost, durability, and the desired performance characteristics when selecting the appropriate method.

- Q: What is the color range available for aluminum sheets?

- The color range available for aluminum sheets is quite diverse and extensive. Aluminum sheets can be found in a variety of standard colors, including but not limited to silver, black, white, bronze, and gold. Additionally, aluminum sheets can be coated with various finishes, such as anodized, painted, or powder coated, which can further expand the color options. These coatings can provide a wide range of colors, including vibrant shades like red, blue, green, yellow, and more. Furthermore, custom colors can also be achieved through specialized processes, allowing for personalized and unique color choices. Overall, the color range available for aluminum sheets is extensive and flexible, catering to various aesthetic preferences and design requirements.

Send your message to us

Aluminum Sheets South Carolina - Aluminium Checkered and Mirror Sheet in Our Warehouse with Better Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords