Aluminum Alloy Sheets for Spaceflight - Aluminium Back Coils for Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

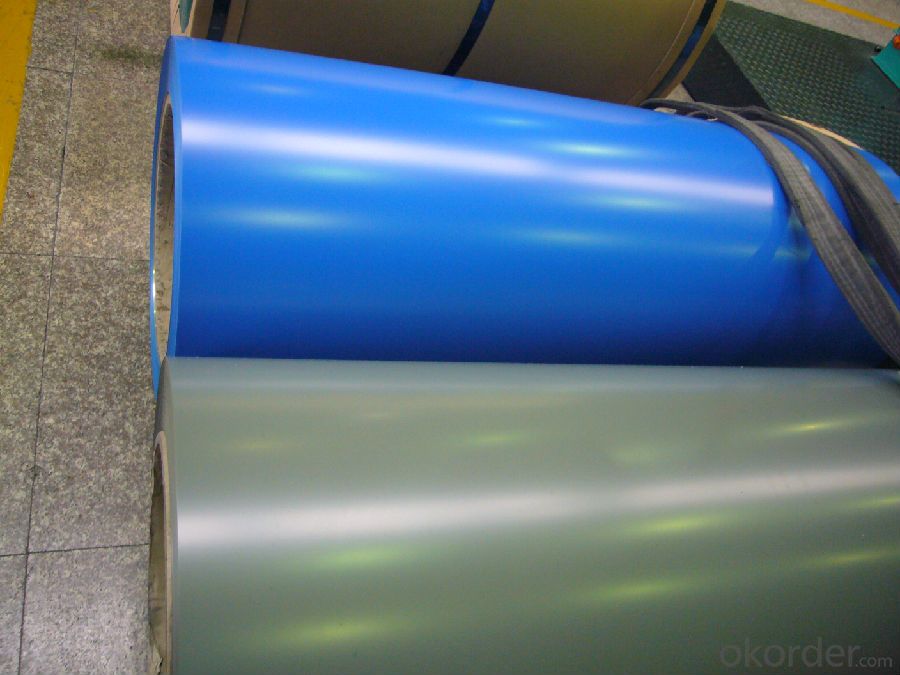

1.Structure of Aluminium Back Coils for Aluminium Composite Panel

Aluminium Back Coils for Aluminium Composite Panel are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of Aluminium Back Coils for Aluminium Composite Panel

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Coating | Coating Thickness | Weight |

| AA1050 | H14 | Polyester | 20-25microns | about 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What is the lifespan of aluminum sheets?

- The lifespan of aluminum sheets can vary depending on various factors such as their usage, environment, and maintenance. However, when properly cared for, aluminum sheets can last for decades or even a lifetime due to their inherent resistance to corrosion and durability.

- Q: Are the aluminum sheets suitable for manufacturing electronics components?

- Absolutely, aluminum sheets are a perfect fit for the production of electronic components. Aluminum, being a lightweight, durable, and reasonably priced material, finds extensive usage in the electronics sector. Its remarkable electrical conductivity is crucial for the efficient operation of electronic devices. Moreover, aluminum sheets can effortlessly be molded, trimmed, and fashioned into diverse components like heat sinks, enclosures, and connectors. Furthermore, aluminum boasts commendable thermal conductivity, enabling it to proficiently disperse heat generated by electronic components. Consequently, aluminum sheets emerge as an optimal selection for the manufacturing of electronic components.

- Q: How does the surface roughness affect the adhesion of coatings on aluminum sheet?

- Surface roughness plays a crucial role in the adhesion of coatings on aluminum sheet. The level of roughness on the surface of the sheet directly impacts the mechanical interlocking between the coating and the substrate, which is essential for strong adhesion. When the surface of the aluminum sheet is smooth, there is limited contact area between the coating and the substrate, resulting in weak adhesion. On the other hand, a rough surface provides more contact points, increasing the interlocking between the coating and the aluminum sheet, leading to improved adhesion strength. Additionally, a rough surface promotes better wetting of the coating material on the aluminum sheet. This means that the coating material can spread more easily over the surface, filling in any gaps or crevices, and creating a more uniform and continuous coating. This improved wetting contributes to enhanced adhesion. Furthermore, a rough surface can also increase the overall surface area of the aluminum sheet. A larger surface area means that there is more available space for the coating material to adhere to, increasing the adhesion strength. It is important to note that there is an optimum level of roughness for achieving the best adhesion. If the surface is excessively rough, it may lead to incomplete coverage of the coating material or the formation of voids, reducing adhesion. Therefore, finding the right balance of roughness is crucial to ensure optimal adhesion of coatings on aluminum sheet.

- Q: Is it suitable to use aluminum windows in areas with cold weather conditions?

- <p>Yes, you can use aluminum windows in cold climates, but there are considerations. Aluminum is a good conductor of heat, which can lead to heat loss in cold weather. To mitigate this, insulated glass units and thermally broken frames can be used. These designs slow down heat transfer, making aluminum windows more energy-efficient in cold climates. Additionally, proper sealing and weatherstripping are crucial to prevent drafts and ensure the windows perform well in low temperatures.</p>

- Q: What are the different grades of aluminum sheets available?

- There are several different grades of aluminum sheets available, including 1100, 3003, 5052, and 6061. These grades vary in terms of their composition, strength, and intended use. 1100 aluminum is the most commercially pure grade and is often used for general purpose applications. 3003 aluminum is alloyed with manganese and has improved strength and corrosion resistance. 5052 aluminum is alloyed with magnesium and has excellent weldability and formability. 6061 aluminum is alloyed with magnesium and silicon and is known for its high strength and versatility.

- Q: Right now I have got some problems on how to machine high purity aluminium machinery,are thery any suggestions to promote for this kind of consecutive issue?

- Aluminum okorder is a soft, silvery-white metal. In high-purity aluminum nearly all impurities have been removed. It is 99.99 percent pure and is machined like other grades of aluminum. To process aluminum for various applications, the manufacturer heats the aluminum in a smelter and then forms it into ingots (large blocks) or billets (log-shaped rods). Using rolling mills, workers machine ingots into aluminum plates, sheets or foils. Dies machine ingots or billets into extrusions or forgings.

- Q: What are aluminum sheets?

- Aluminum sheets, commonly found in various industries and applications, are thin and flat pieces of aluminum. Aluminum, a lightweight and versatile metal, is known for its exceptional strength, durability, and corrosion resistance, from which these sheets are made. Depending on the project's specific requirements, the thickness, width, and length of these sheets can vary. Construction, automotive, aerospace, packaging, and manufacturing industries, among others, widely employ aluminum sheets. They serve various purposes, including roofing, cladding, signage, transportation, electrical enclosures, and even household utensils. Aluminum's flexibility and malleability make it a popular choice for a wide range of applications, as it can be easily shaped and formed. Furthermore, aluminum sheets can be coated or finished, enhancing their appearance and protecting them from external factors like moisture, UV rays, or chemicals. In summary, aluminum sheets are indispensable materials that offer a combination of lightweight, strength, and corrosion resistance, making them ideal for industrial and commercial uses.

- Q: What are the common thicknesses of aluminum sheets used in aerospace applications?

- In aerospace applications, aluminum sheets are commonly used due to their lightweight and high strength properties. The thickness of aluminum sheets used in aerospace applications can vary depending on the specific requirements of the component or structure being fabricated. Commonly used thicknesses for aluminum sheets in aerospace applications range from 0.016 inches (0.4 mm) to 0.25 inches (6.35 mm). These thicknesses are selected based on factors such as the desired strength-to-weight ratio, structural integrity, and the specific application or component being manufactured. Thinner aluminum sheets, such as those with a thickness of 0.016 to 0.040 inches, are often used for lightweight structures, interior components, and non-critical parts. These thinner sheets provide the necessary strength while minimizing weight. For more structural components, thicker aluminum sheets are employed. Thicknesses between 0.040 and 0.125 inches are commonly used for structural elements like floor panels, bulkheads, and wing ribs. These sheets offer increased strength and rigidity for supporting the aircraft's weight and managing the stresses experienced during flight. In certain cases, even thicker aluminum sheets may be used, ranging from 0.125 to 0.25 inches, for heavy-duty structural components or areas where additional strength is required. These thicker sheets are utilized in critical parts such as landing gear components, wing spars, and engine mounts to ensure the necessary structural integrity and load-bearing capability. It is important to note that these are general ranges, and the specific thickness requirements may vary depending on the aircraft type, design specifications, and the particular application within the aerospace industry.

- Q: Can aluminum sheets be used for insulation jackets?

- Indeed, insulation jackets can indeed employ aluminum sheets. Aluminum possesses exceptional thermal conductivity characteristics, enabling it to proficiently deflect heat and hinder the transmission of thermal energy. Consequently, it becomes the perfect substance for insulation jackets, as it aids in preserving temperature regulation and reducing heat loss or gain. Furthermore, aluminum sheets are lightweight, long-lasting, and impervious to corrosion, rendering them a pragmatic option for insulation applications.

- Q: Are aluminum sheets suitable for marine hulls?

- Indeed, marine hulls can indeed be made using aluminum sheets. The utilization of aluminum in boat construction is widespread due to its numerous advantageous properties. The lightweight nature of aluminum enables enhanced fuel efficiency and increased speed. Furthermore, its exceptional resistance to corrosion renders it well-suited for prolonged exposure to saltwater. Moreover, aluminum possesses remarkable strength and durability, thereby ensuring the integrity of the hull's structure. Additionally, aluminum can be easily manipulated into intricate shapes, allowing for the creation of innovative hull designs. In summary, aluminum sheets represent a dependable and efficient option for marine hulls, delivering a robust and corrosion-resistant framework that enhances the boat's performance and lifespan.

Send your message to us

Aluminum Alloy Sheets for Spaceflight - Aluminium Back Coils for Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords