Alloy Tool Steel,Alloy Steel Bar Steel Material SKD61

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Type:

Alloy Steel

Shape:

Steel Round Bar

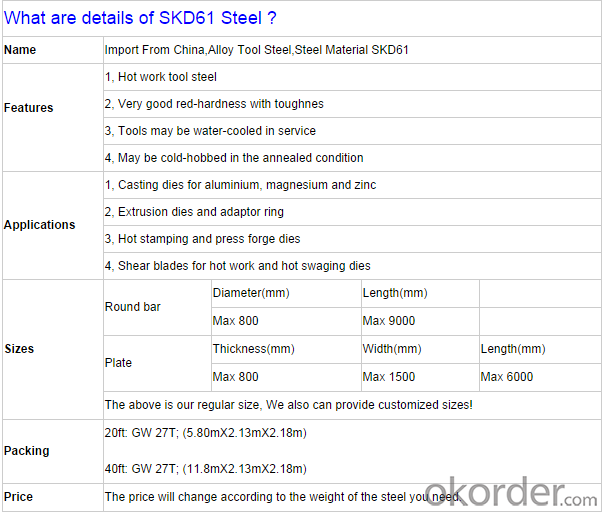

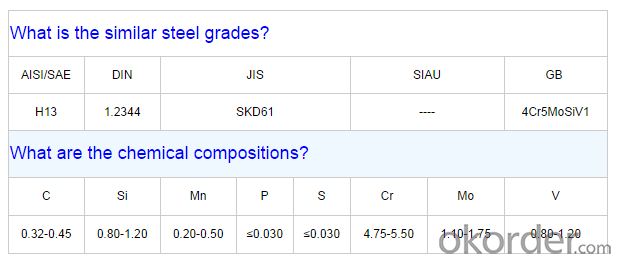

Alloy Tool Steel,Alloy Steel Bar Steel Material SKD61

Product information:

Product show

Workshop show

Our service:

- Q: How does the heat treatment process affect the hardness of special steel?

- The heat treatment process has a significant impact on the hardness of special steel. Heat treatment involves heating the steel to a specific temperature, holding it at that temperature for a certain period, and then cooling it at a controlled rate. This process alters the microstructure of the steel, which in turn affects its hardness. One of the most common heat treatment techniques is quenching, which involves rapid cooling of the steel. Quenching results in the formation of a hard and brittle microstructure called martensite. The rapid cooling prevents the formation of other softer microstructures, such as pearlite or ferrite, and thus increases the hardness of the steel. Another heat treatment process that affects the hardness of special steel is tempering. After quenching, the steel is often tempered to reduce its brittleness and improve its toughness. Tempering involves reheating the quenched steel to a lower temperature and then slowly cooling it. This process allows for the transformation of some of the martensite into a more ductile microstructure, such as tempered martensite or bainite. These microstructures retain some of the hardness of martensite but also provide improved toughness and resistance to fracture. In summary, the heat treatment process significantly affects the hardness of special steel. Quenching increases hardness by forming martensite, while tempering balances hardness with improved toughness. The specific heat treatment parameters, such as temperature and cooling rate, can be adjusted to achieve the desired hardness and mechanical properties for different applications of special steel.

- Q: How does special steel contribute to the renewable energy industry?

- Special steel plays a crucial role in the renewable energy industry by providing the necessary strength, durability, and resistance to extreme conditions for various applications. It is used in wind turbines, solar panels, and hydroelectric infrastructure, enabling the efficient and reliable generation of renewable energy. Special steel also helps enhance the performance, efficiency, and lifespan of these renewable energy systems, ultimately contributing to the sustainability and growth of the industry.

- Q: What grade of iron powder should be used for processing special steel? Are there any other elements on the request? How much are they?

- The main special steel carbon structural steel, carbon tool steel, carbon spring steel, alloy spring steel, alloy structural steel, bearing steel, alloy tool steel, alloy tool steel, high-speed tool steel, stainless steel, heat-resistant steel and high-temperature alloy, precision alloy, gold and other electric heating.

- Q: How does special steel perform in stamping applications?

- The unique properties of special steel make it an excellent choice for stamping applications. Its high strength and durability ensure that it can withstand wear and tear during the stamping process, resulting in longer tool life and reduced maintenance costs. Additionally, special steel's heat resistance allows it to maintain its structural integrity even at high temperatures, preventing warping or deformation. Its exceptional dimensional stability ensures precise and consistent results, while its excellent formability allows for the creation of intricate designs. Overall, special steel's properties make it a reliable and versatile option for a wide range of stamping applications.

- Q: How does special steel perform in terms of corrosion resistance in acidic environments?

- Special steel, also known as stainless steel, is highly regarded for its exceptional corrosion resistance in various environments, including acidic conditions. It contains a minimum of 10.5% chromium, which forms a protective layer on the surface of the steel known as a passive film. This passive film acts as a barrier, preventing the steel from coming into direct contact with the corrosive elements present in acidic environments. The chromium content in special steel enables it to react with oxygen in the atmosphere, creating a thin and transparent oxide layer. This oxide layer is highly stable and self-healing, making stainless steel highly resistant to corrosion caused by acids. The presence of other alloying elements such as nickel and molybdenum further enhances its resistance to acidic corrosion. In acidic environments, special steel exhibits excellent resistance to both general corrosion and localized corrosion, such as pitting and crevice corrosion. It can withstand a wide range of acid concentrations and temperatures, making it suitable for applications in industries such as chemical processing, pharmaceuticals, and marine environments where exposure to acidic solutions is common. It is important to note that the performance of special steel in acidic environments may vary depending on the specific grade and composition of the steel. Different grades of stainless steel have varying levels of alloying elements, which can influence their corrosion resistance properties. Therefore, it is essential to select the appropriate grade of special steel that matches the specific acidic environment to ensure optimal performance and longevity.

- Q: How does special steel contribute to the automotive aftermarket industry?

- Special steel plays a significant role in the automotive aftermarket industry by offering various advantages that contribute to the overall performance, durability, and safety of vehicles. Firstly, special steel is known for its exceptional strength and durability. This property allows automotive manufacturers and aftermarket suppliers to develop high-performance components and parts that can withstand extreme conditions and heavy usage. Components such as engine parts, suspension systems, and chassis components benefit from the superior strength of special steel, ensuring their longevity and reliability. Additionally, special steel offers excellent corrosion resistance, which is crucial for automotive components exposed to various weather conditions and road environments. By using corrosion-resistant steel, aftermarket suppliers can produce parts that are less prone to rust and degradation, ultimately enhancing the lifespan of vehicles and reducing the need for frequent replacements. Furthermore, special steel enables the production of lightweight components without compromising on strength. With the increasing demand for fuel efficiency and reduced emissions, lightweight materials are highly sought after in the automotive industry. By utilizing special steel, aftermarket suppliers can create lightweight parts that contribute to improved fuel economy and overall performance of vehicles. Moreover, special steel's versatility allows for the development of complex and intricate components, contributing to advancements in vehicle technology. From precision-engineered gears and shafts to specialized parts for electric vehicles, special steel can be tailored to meet specific automotive requirements, supporting the industry's continuous innovation. Lastly, special steel offers cost-effectiveness in the automotive aftermarket industry. Although the initial cost of special steel might be higher than conventional steel, its durability and longevity result in reduced maintenance and replacement costs over time. This benefit is particularly significant for aftermarket suppliers and vehicle owners, as it helps minimize expenses and ensures a higher return on investment. In conclusion, special steel plays a vital role in the automotive aftermarket industry by providing strength, durability, corrosion resistance, lightweight properties, versatility, and cost-effectiveness. These qualities contribute to the overall performance, safety, and longevity of vehicles, making special steel a crucial material in the development of high-quality aftermarket components and parts.

- Q: How does special steel compare to other materials like aluminum or titanium?

- Special steel, such as stainless steel or tool steel, offers several advantages over materials like aluminum or titanium. Firstly, special steel generally exhibits higher strength and hardness, making it ideal for applications requiring durability and resistance to wear. Secondly, special steel possesses excellent thermal conductivity, allowing it to dissipate heat more efficiently compared to aluminum or titanium. Additionally, special steel is often more cost-effective and readily available in comparison to titanium. However, aluminum and titanium are known for their lightweight properties, making them preferable for applications where weight reduction is crucial. Ultimately, the choice between special steel, aluminum, or titanium depends on the specific requirements and constraints of the intended application.

- Q: What are the properties of weathering steel?

- Weathering steel, also known as corten steel, possesses several distinctive properties. It exhibits high resistance to corrosion, making it suitable for outdoor structures without the need for protective coatings. Its unique composition allows for the formation of a stable rust-like appearance, providing an aesthetically pleasing and natural finish. Moreover, weathering steel has excellent strength and durability, making it ideal for various applications, including bridges, buildings, and architectural elements.

- Q: What are the common alloying elements in special steel?

- Some common alloying elements in special steel include chromium, nickel, molybdenum, and vanadium. Chromium is often added to improve the steel's corrosion resistance and enhance its hardness. Nickel is used to increase the steel's toughness and resistance to extreme temperatures. Molybdenum is another element that is frequently added to enhance the steel's strength and improve its resistance to wear and corrosion. Vanadium is known for its ability to increase the steel's hardness and strength, making it suitable for applications that require high durability. These alloying elements are carefully selected and added to special steel to achieve specific properties and meet the unique requirements of various industries such as automotive, aerospace, and construction.

- Q: Can special steel be used in the agricultural industry?

- Yes, special steel can be used in the agricultural industry. It is often utilized in the manufacturing of various farm equipment and machinery, such as plows, harrows, cultivators, and tractor components. Special steel's high strength, durability, and resistance to corrosion make it suitable for withstanding the demanding conditions and prolonged use in agricultural operations.

Send your message to us

Alloy Tool Steel,Alloy Steel Bar Steel Material SKD61

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords