Fin Tube Aluminum Coils - Alloy 3003 PVDF Aluminum Coil for Roofing/Ceiling/Gutter/Decoration

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

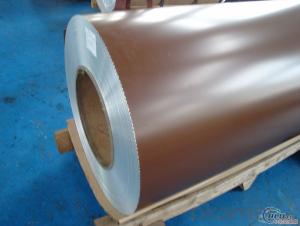

Alloy 3003 PVDF Aluminium Coil for Roofing/Ceiling/Gutter/Decoration

Specification

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.05~10mm |

Width | <1600mm< span=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~25micron(EN ISO-2360:1995) PVDF25 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

Payment | L/C ,T/T |

Packing

FAQ

Q: How can I request a product sample? A: The samples are free but freight should be collected. Please send sample list and courier account number by email.

Q: How can I request a product catalog? A: The hard copies of catalogs are free but freight should be collected. Please send courier account number by email. You are suggested to request a PDF catalog.

Q: Wha's your payment terms? A: One is T/T 30% before production and 70% against copy of B/L; the other is Irrevocable L/C 100% at sight.

Q: What's your trade terms? A: FOB, CNF(CFR), CIF, EXW.

Q: How long is the quality guarantee? A: All of our products have a period of quality guarantee since time of shipment. Please contact your salesman for more details, as different products enjoy different time of guarantee

- Q: How do aluminum coils contribute to energy-efficient appliances?

- Aluminum coils play a key role in enhancing the energy efficiency of appliances. The use of aluminum in coil form allows for efficient heat transfer, which is essential for appliances that require cooling or heating mechanisms. Firstly, aluminum coils have excellent thermal conductivity. This means that they can quickly absorb and dissipate heat, resulting in more efficient cooling or heating processes. This is especially important in appliances such as refrigerators, air conditioners, and heat pumps, where effective heat transfer is crucial for maintaining the desired temperature. Moreover, aluminum coils are lightweight yet durable, making them an ideal choice for energy-efficient appliances. The lightweight nature of aluminum reduces the overall weight of the appliance, which leads to lower energy consumption during transportation and installation. Additionally, the durability of aluminum ensures a longer lifespan for the appliance, reducing the need for frequent maintenance or replacement. Furthermore, aluminum is highly resistant to corrosion, which is a common issue in appliances that involve contact with water or moisture. By using aluminum coils, manufacturers can ensure the longevity and reliability of the appliance, thus contributing to energy efficiency by reducing the need for repairs or replacements. Lastly, aluminum is a highly recyclable material. Using aluminum coils in appliances promotes sustainability and reduces the environmental impact. By choosing energy-efficient appliances that incorporate aluminum coils, consumers can support the circular economy and contribute to a more sustainable future. In conclusion, aluminum coils greatly contribute to the energy efficiency of appliances. Their excellent thermal conductivity, lightweight yet durable nature, corrosion resistance, and recyclability make them an ideal choice for enhancing the performance and sustainability of energy-efficient appliances.

- Q: How are aluminum coils cut to size?

- Aluminum coils are typically cut to size using specialized coil slitting machines. These machines have rotating circular blades that make precise cuts along the length of the coil. The coil is fed through the machine, and the blades cut the aluminum into the desired width. The cut pieces are then collected and further processed or used for various applications.

- Q: Can aluminum coils be used in the production of architectural façades?

- Yes, aluminum coils can be used in the production of architectural façades. Aluminum is a popular material choice for façades due to its durability, lightweight nature, and aesthetic appeal. The use of aluminum coils in façade production allows for easy customization, as they can be easily formed and shaped into various designs and profiles. Additionally, aluminum is resistant to corrosion, making it suitable for exterior applications. It also offers excellent thermal and acoustic insulation properties, contributing to energy efficiency and soundproofing. Overall, aluminum coils provide a versatile and efficient option for the production of architectural façades.

- Q: I have a 94 Gt Mustang that has had a little work done to it so far. The boy I bought it from had an aftermarket cam put in it, had the heads ported and polished. He also had the heads shaved a little. My question is.........Would having aluminum heads with roller rocker arms installed help it enough to justify doing it. If it would, how Much would it help? I am not exactly sure how much life and duration my cam is running, but it idle pretty rough. I believe my compression is about 9.5 to 1.

- If you go to roller rockers you should do it with the cam and lifters as well as the valve springs so they all match Just adding aluminum heads with roller rockers is like a fish with-out a bicycle! It doesn't make any sense. It all has to match up or you get problems instead of freer movement........and that's what rollers are about ......freeing up the drag caused by friction in the mechanical valve train.

- Q: Is it possible to use aluminum coils as a material for insulation?

- <p>Aluminum coils are not typically used for insulation materials. Aluminum is a good conductor of heat and electricity, which makes it unsuitable for insulation purposes where the goal is to prevent the flow of heat or electricity. Insulation materials are usually poor conductors of heat, such as fiberglass, mineral wool, or plastic foams, which help to retain heat within a space or prevent the loss of heat to the environment. Aluminum coils are more commonly used in applications where heat transfer is desired, such as in heat exchangers or electrical wiring.</p>

- Q: What are the various surface finishes available for aluminum coils?

- Aluminum coils offer a variety of surface finishes to meet different needs and preferences. The options include: 1. Mill Finish: This is the most basic and natural finish achieved by passing the coil through rollers during manufacturing. It gives the aluminum a smooth, shiny appearance. 2. Anodized Finish: Anodizing is an electrochemical process that adds a protective layer to the aluminum coil's surface. It comes in various colors and provides enhanced resistance to corrosion, abrasion, and wear. Architects commonly use anodized finishes. 3. Painted Finish: Aesthetic appeal and environmental protection can be achieved by coating aluminum coils with paint. The paint comes in different colors and finishes, such as matte, glossy, or metallic. 4. Brushed Finish: By brushing the surface with abrasive materials, aluminum coils can have a textured appearance with fine lines or scratches. Brushed finishes are often used for decorative purposes. 5. Polished Finish: Buffing the surface of the aluminum coil creates a smooth, reflective finish. It gives a mirror-like appearance and is commonly used for decorative and architectural applications. 6. Embossed Finish: Embossing involves stamping or pressing a pattern or design onto the surface of the aluminum coil. This finish adds texture and depth, making it suitable for non-slip surfaces or decorative purposes. 7. Laminated Finish: Lamination involves bonding a thin layer of film or foil to the aluminum coil's surface. This finish provides additional protection against scratches, stains, or UV radiation. It is commonly used for applications that require durability and resistance. These examples highlight the range of surface finishes available for aluminum coils. The choice of finish depends on specific application requirements, desired appearance, and functional properties needed for the end product.

- Q: Is it possible to use a metal detector to locate an aluminum coil?

- <p>Yes, you can use a metal detector to detect aluminum coils. Metal detectors are designed to detect various types of metal, including aluminum. While they are often used for detecting ferrous metals like iron, they can also pick up non-ferrous metals such as aluminum. The effectiveness of detecting aluminum may vary depending on the type of metal detector and its sensitivity settings. Ground conditions and the size and composition of the aluminum coil can also affect detection. It's important to adjust the metal detector to the appropriate settings for detecting non-ferrous metals to increase the chances of successful detection.</p>

- Q: What are the different coil annealing options available for aluminum coils?

- There are several coil annealing options available for aluminum coils, including batch annealing, continuous annealing, and stress relief annealing. Batch annealing involves heating the coils in a controlled atmosphere furnace and then allowing them to cool slowly. Continuous annealing, on the other hand, involves passing the coils through a series of induction or gas-fired heating zones with controlled cooling. Stress relief annealing is a process used to relieve internal stresses in the coils, typically performed at a lower temperature for a longer duration.

- Q: Are there any limitations on the length of aluminum coils?

- There are indeed limitations on the length of aluminum coils. While aluminum coils can be produced in various lengths, they are typically limited by practical factors such as transportation, handling, and manufacturing capabilities. Transportation is one of the major limitations as longer coils may become difficult to move efficiently. The size and weight of longer coils can pose challenges for loading and unloading, as well as shipping and logistics. Additionally, longer coils may require specialized equipment for transportation, which can add to the overall cost and complexity. Handling is another limitation, as longer coils can be harder to maneuver and manipulate during various stages of production. They may require larger and more robust machinery to process, which may not be available or feasible in all manufacturing facilities. Furthermore, manufacturing capabilities can impose restrictions on the length of aluminum coils. The equipment used to produce coils may have certain limitations in terms of size and capacity. Coil processing lines and machinery may have maximum lengths they can handle, and exceeding these limits may not be possible or economically viable. In summary, while there is no specific universal limit on the length of aluminum coils, logistical, handling, and manufacturing constraints can impose practical limitations. The specific length of aluminum coils would depend on various factors including transportation, handling capabilities, and the manufacturing processes involved.

- Q: Can aluminum coils be used in the production of aluminum sunshades?

- Yes, aluminum coils can be used in the production of aluminum sunshades. Aluminum coils are typically used as a starting material in the manufacturing process of aluminum sunshades. These coils are made from high-quality aluminum, which is known for its lightweight and durable properties. The coils are then fabricated and shaped into the desired form for the sunshade, whether it be slats, louvers, or a solid panel. Aluminum is a popular choice for sunshades due to its corrosion resistance and ability to withstand various weather conditions. Additionally, aluminum is easily recyclable, making it an environmentally friendly material for sunshade production. Overall, aluminum coils are an essential component in the production of aluminum sunshades, providing strength, durability, and aesthetic appeal to these shading structures.

Send your message to us

Fin Tube Aluminum Coils - Alloy 3003 PVDF Aluminum Coil for Roofing/Ceiling/Gutter/Decoration

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords