Al-Zinc coated Steel coil For Construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

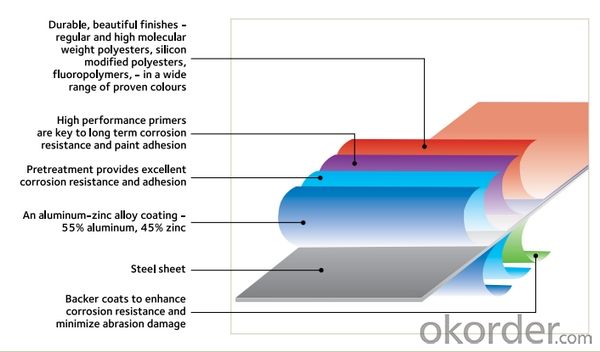

Structure of Al-Zinc coated steel coil

Description of Aluminum Zinc Rolled Coil

The detailed information for the Al-Zinc coated steel coil is as following and it is mainly using for roofing producing, making ceiling grid and all kinds of roll forming structure.

Thickness: 0.20mm to 1.20mm

Width: 914mm, 1000mm, 1200mm, 1219mm and 1250mm, or slit narrow strip according to customer request, can be slit from 20mm to 610mm.

Coil ID: 508mm

Coil weight: 3 tons to 6 tons

Thickness tolerance: +/- 0.02mm or according to customer request.

Main Feature of Al-Zinc coated steel coil

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Al-Zinc coated steel coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Al-Zinc coated steel coil

Prepainted galvanized steel coil ( PPGI ) | Prepainted galvalume steel coil ( PPGL ) | |

Standard | JIS G3312 CGCC | J IS G3322 CGLCC |

Valid thickness | 0. 16 ~1. 2 0mm | 0. 16 ~1. 2 0mm |

Coil width | 600~1250mm | 600~1250mm |

Coil ID | 508mm & 610mm | 508mm & 610mm |

Coil weight | 3~5 tons | 3~5 tons |

Coating | 4 0~275 g/m2 | AZ30 to AZ150 |

Paint t hickness , top side | 15~25 microns | 15~25 microns |

P aint t hickness , reverse | 5~7 microns or 15~25 microns | 5~7 microns or 15~25 microns |

Color | any RAL code | any RAL code |

Package | vertical, eye to sky & horizontal | vertical, eye to sky & horizontal |

MOQ | 25 tons | 25 tons |

FAQ of Al-Zinc coated steel coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the safety precautions when working with steel coils?

- Some safety precautions when working with steel coils include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots, ensuring proper lifting techniques to prevent musculoskeletal injuries, maintaining a clear and organized work area to avoid tripping hazards, using proper machinery and equipment to handle and transport the coils safely, and following established safety protocols and procedures. It is also important to receive proper training and supervision to handle steel coils effectively and minimize potential risks.

- Q: All the appliances in my kitchen are stainless steel, and I hate how they look becuase every time I wash them they are full of streaks. Is there a good cleaner made for stainless steel that won't leave streaks?

- I like Cerama Bryte. They make several stainless steel cleaning products. I love the Stainless Steel Cleaning Polish Conditioner Wipes. They also make Stainless Steel Appliance Cleaner.

- Q: How are steel coils used in the manufacturing of engine mounts?

- Steel coils are used in the manufacturing of engine mounts to provide structural support and absorb vibrations generated by the engine. The coils are designed to provide tension and flexibility, allowing the engine to be securely mounted while minimizing the transmission of vibrations to the rest of the vehicle.

- Q: What are the different types of steel coil loading and unloading methods used during processing?

- Some of the different types of steel coil loading and unloading methods used during processing include overhead cranes, forklifts, coil cars, and coil transfer systems.

- Q: What are the common quality control measures for steel coils?

- There are several common quality control measures that are implemented for steel coils to ensure their performance and reliability. These measures are crucial in maintaining the overall quality of the steel coils and ensuring that they meet the required standards and specifications. Firstly, dimensional checks are conducted to ensure that the steel coils have the correct thickness, width, and length. This is important as any deviations from the specified dimensions can greatly affect the performance and usability of the coils. Next, visual inspections are carried out to identify any surface defects or imperfections such as scratches, dents, or corrosion. These inspections help in identifying any potential issues that may compromise the structural integrity of the coils or affect their aesthetic appearance. Furthermore, mechanical property tests are conducted to determine the strength, hardness, and other mechanical characteristics of the steel coils. These tests help in assessing the performance and durability of the coils under different conditions and loads. Chemical composition analysis is also an important quality control measure for steel coils. This involves analyzing the composition of the steel, including the presence of any impurities or elements that may affect its properties. It ensures that the steel coils are made from the correct grade and meet the required chemical specifications. Coating inspections are another vital quality control measure. If the steel coils are coated with protective layers, it is essential to check the adhesion, thickness, and uniformity of the coatings. This helps in ensuring that the coils have adequate protection against corrosion and other environmental factors. Lastly, various non-destructive testing methods such as ultrasonic testing, magnetic particle inspection, or eddy current testing are employed to identify any internal defects or abnormalities in the steel coils. These tests help in detecting issues such as cracks, inclusions, or discontinuities that are not visible through visual inspection. Overall, the common quality control measures for steel coils include dimensional checks, visual inspections, mechanical property tests, chemical composition analysis, coating inspections, and non-destructive testing. These measures are essential in maintaining the quality and reliability of steel coils and ensuring that they meet the required standards and customer expectations.

- Q: What are the main factors that affect the price of steel coils?

- The main factors that affect the price of steel coils are the cost of raw materials, supply and demand dynamics, production and transportation costs, changes in government policies and regulations, and global economic conditions.

- Q: What are the dimensions of steel coils used in the furniture industry?

- The dimensions of steel coils used in the furniture industry can vary depending on the specific application and requirements of the furniture manufacturer. However, typically, steel coils used in the furniture industry have dimensions ranging from 0.20mm to 3.00mm in thickness and 600mm to 2000mm in width. The length of the coils can also vary, but it is commonly around 1000mm to 3000mm. These dimensions allow for flexibility in shaping and forming the steel coils into various furniture components such as frames, springs, and structural supports.

- Q: i recently got an industrial piercing and instead of getting pierced with a metal bar i have a PTFE bar .. i eventually want to put in a metal bar but what kind do i get? whats the difference between a surgical steel and titanium bar?thanks

- 316L steel is the most basic metal used in body jewelry. It is the basic requirement of metal to be used in initial piercings and for healing. There are better grades but usually they cost more as well. For most people this grade of steel works just fine. Titanium is usually preferred over steel because it contains no nickel and it weighs almost 50% less than steel. Titanium can come in plain polish which looks just like steel AND it can come in a variety of colors (but NOT red or black). Titanium is super for people with sensitive skin to steel. It does cost a little more but is well worth it.

- Q: What are the common coil widths available for steel coils?

- The common coil widths available for steel coils typically range from 24 inches to 72 inches, with 36 inches and 48 inches being the most common options.

- Q: Just two sentences on a detailed description on what the steel industry is

- The steel industry is an industry that produces steel. It is one of the largest industries in the world, with China as the leading steel producer

Send your message to us

Al-Zinc coated Steel coil For Construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords