AISI A240 304 Stanless Steel Plate 8K for Elevator Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 23000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

roduct Details | |

Product name | Stainless steel plate |

Brand name | RONSCO |

Standard | ASTM A240, ASTM A480, EN10088, JIS G4305 |

Material | 304, 316L, 321, 310S, 1.4301, 1.4307, 1.4404, S31803, S32750, 904L, Monel 400, Inconel 800 |

Surface | NO.1,2B,NO.4,BA,SB,Satin,Brushed,Hairline,Mirror |

Certificate | ISO9001, CE, SGS, TUV, DNV, BV, LR, GL, NK, RMRS |

Packing | In wooden cases,in wooden pallets |

Shipment | By sea, by air, by express |

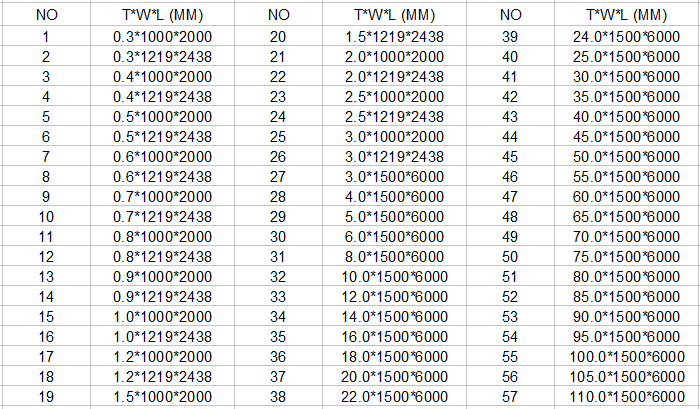

Specifications |

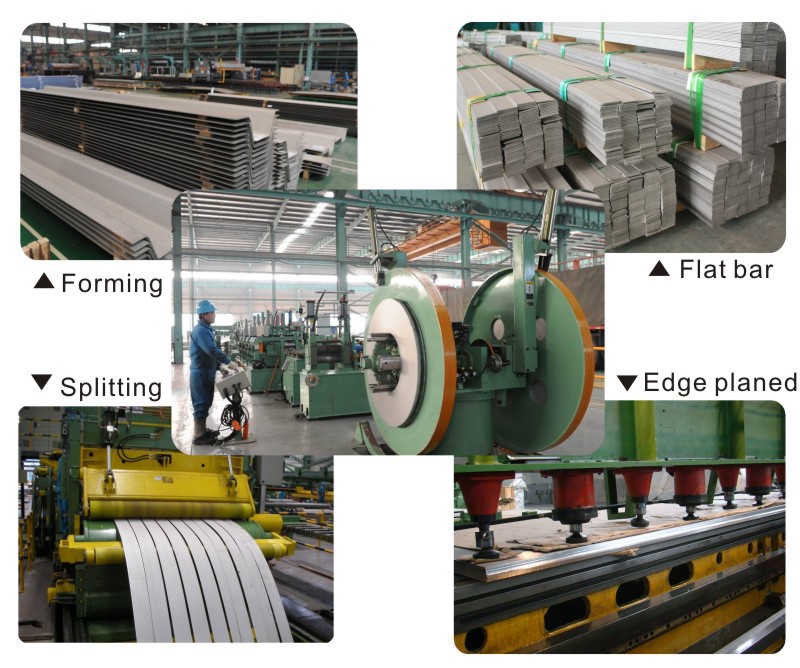

Finished Products

Stocks of the 201 stainless steel sheet

Why choose us?

19 Years specialized in processing,sales and technical services of high quality stainless steel plates and coils.

Our company located in Chariman Mao's hometown- Changsha,Hunan Province,we provide stainless steel plates and coils to our customers all over the world.

One of the biggest agent of Baosteel,TISCO in the South of China.

6 processing platform such as "Shearing,cutting,surface finish,forming,welding and machine platforms".

- Q: What is the difference between brushed and polished stainless steel sheets?

- The main difference between brushed and polished stainless steel sheets lies in their surface finish. Brushed stainless steel sheets have a textured, linear pattern created by brushing the surface with abrasive materials, giving it a matte appearance. On the other hand, polished stainless steel sheets have a smooth, reflective surface achieved by polishing the steel with a fine abrasive compound.

- Q: How to clean stainless steel plate cleaning?

- The mild way to clean stainless steel is simply to use hot water and clean soft cloth to wipe the surface, and then use dry metal with other soft cloth to prevent water stains thoroughly. I'm surprised at how much dirt on the surface comes to my pizza oven, just this step. When using this or any other way, please remember, "grain" stainless steel has run the whole surface in one direction on the minor groove metal and its best grain, rather than across it clean. Some people will tell you that this is to avoid scratching the metal or lodging the dust particles in the foods, where they can cause rust to form. This is likely to be true, but scrubbing food seems to be easier and more effective.

- Q: Can stainless steel sheets be used for automotive exhaust systems?

- Yes, stainless steel sheets can be used for automotive exhaust systems. Stainless steel is a popular material choice for exhaust systems due to its excellent corrosion resistance, high temperature resistance, and durability. It can withstand the harsh conditions of the exhaust system, including high heat, moisture, and chemicals. Stainless steel sheets can be formed and fabricated into various components of the exhaust system, such as pipes, mufflers, and catalytic converters. They provide long-lasting performance, reduce the risk of rust and corrosion, and contribute to the overall efficiency and longevity of the automotive exhaust system.

- Q: Can stainless steel sheets be used for heat transfer applications?

- Yes, stainless steel sheets can be used for heat transfer applications. Stainless steel has excellent thermal conductivity, making it suitable for transferring heat efficiently between two surfaces or mediums. It is commonly used in heat exchangers, cookware, and other applications where heat transfer is essential.

- Q: Can stainless steel sheets be bent or formed?

- Yes, stainless steel sheets can be bent or formed. Stainless steel has good ductility, allowing it to be easily shaped into different forms through various processes such as bending, rolling, or forming.

- Q: Can stainless steel sheets be cut to size?

- Certainly, it is possible to cut stainless steel sheets to the desired size. These sheets are incredibly versatile and can be readily tailored to meet specific dimensions and needs. Multiple cutting techniques, including plasma cutting, laser cutting, or waterjet cutting, can be utilized for this purpose. These methods guarantee precise and accurate cuts, maintaining the integrity of the stainless steel sheet while achieving the desired size. Moreover, stainless steel's remarkable durability and resistance to corrosion make it an ideal choice for applications involving cutting and shaping.

- Q: Can stainless steel sheets be etched with designs?

- Indeed, designs can certainly be etched onto stainless steel sheets. Stainless steel, being a flexible material, offers the option of etching through different techniques like chemical etching or laser engraving. Chemical etching involves the application of a corrosive substance onto the stainless steel surface. This substance selectively eliminates the unprotected areas, leaving the desired design etched onto the sheet. On the other hand, laser engraving employs a high-powered laser beam to etch the design onto the stainless steel surface. Both methods yield intricate and detailed designs on stainless steel sheets, making it highly sought after for decorative and functional purposes in numerous industries.

- Q: Can stainless steel sheets be used for jewelry making?

- Yes, stainless steel sheets can be used for jewelry making. Stainless steel is a popular material for creating jewelry due to its durability, resistance to tarnishing, and hypoallergenic properties. It can be easily cut, shaped, and textured to create unique designs. Stainless steel sheets can be used to make various types of jewelry, including earrings, rings, bracelets, pendants, and even intricate chains. Additionally, stainless steel jewelry is often more affordable compared to precious metals like gold or silver, making it a popular choice for budget-conscious individuals or those looking for a more modern and industrial aesthetic.

- Q: Are stainless steel sheets suitable for cryogenic storage containers?

- Yes, stainless steel sheets are suitable for cryogenic storage containers. Stainless steel is known for its excellent low-temperature properties, making it an ideal choice for cryogenic applications. It has a high resistance to thermal expansion and contraction, making it less prone to cracking or leaking at extremely low temperatures. Additionally, stainless steel is highly durable, corrosion-resistant, and can withstand the extreme conditions of cryogenic storage, ensuring the safety and integrity of the stored materials. Therefore, stainless steel sheets are widely used in the construction of cryogenic storage containers in various industries such as pharmaceuticals, aerospace, and scientific research.

- Q: Are stainless steel sheets suitable for chemical reactors?

- Yes, stainless steel sheets are suitable for chemical reactors. Stainless steel is a preferred material in the chemical industry because of its excellent corrosion resistance properties. It can withstand a wide range of chemicals, including acids, alkalis, and solvents, without undergoing significant degradation or reacting with the substances being processed. Stainless steel sheets are particularly chosen for chemical reactors due to their high strength, durability, and resistance to high temperatures and pressure. They can handle the harsh conditions and aggressive substances found in chemical processes without compromising their structural integrity. Moreover, stainless steel sheets are easy to clean and maintain, making them suitable for applications where cleanliness is crucial, such as pharmaceutical and food processing industries. They also have excellent heat transfer properties, allowing for efficient temperature control within the reactor. In summary, stainless steel sheets are a reliable choice for chemical reactors due to their corrosion resistance, strength, durability, and thermal properties. They provide a safe and long-lasting solution for handling various chemicals, making them widely used in the chemical industry.

Send your message to us

AISI A240 304 Stanless Steel Plate 8K for Elevator Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 23000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords