AISI 1045 Round bar Special Steel Carbon Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Chemical Composition(GB)%

| standard | C | Si | Mn | P | S | Ni | Cr | Cu |

| 45 | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 | ≤0.035 | ≤0.035 | ≤0.30 | ≤0.15 | ≤0.25 |

| S45C | 0.42-0.48 | 0.15-0.35 | 0.60-0.90 | ≤0.030 | ≤0.035 | ≤0.20 | ≤0.20 | ≤0.230 |

Heat Treatment

| Item | Temperature ℃ | Hardness |

| normalizing | 850-870 | 170-217HBS |

Characterstics

| 1.Commonly used in carbon quenched and tempered steels |

| 2.Higher strength and better cutting processability |

Applications

| 1.Suitable for cold stamping die wedge, screw, plate, etc |

| 2.Other parts of cold work mould |

| 3.Used for hot forging, die casting, hot stamping and hot mould parts |

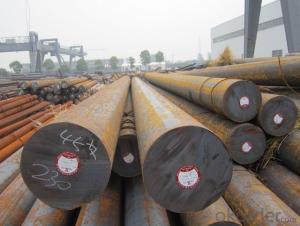

Product show

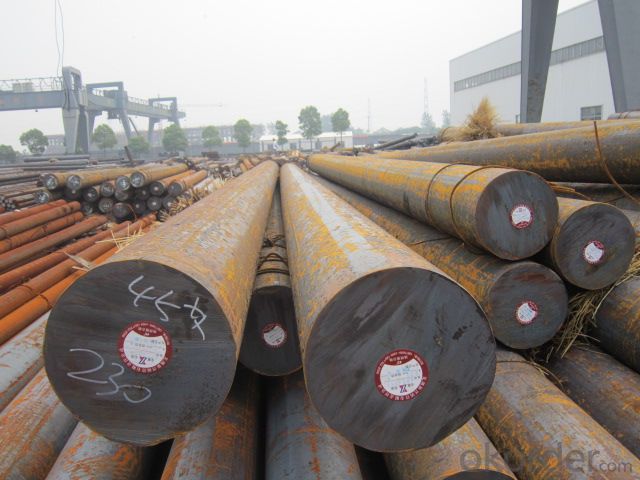

Workshop show

FAQ:

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

4, Trading Terms?

EXW, FOB, CIF, FFR, CNF

5, After-sale Service?

We provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How does special steel contribute to the marine industry?

- The marine industry greatly relies on special steel due to its exceptional strength, durability, and corrosion resistance, which are vital qualities for various marine applications. A significant role of special steel in the marine industry lies in the building of ships and submarines. These vessels face harsh environmental conditions, such as exposure to saltwater, extreme temperatures, and high pressures. Special steel, such as high-strength low-alloy (HSLA) steel or stainless steel, ensures the structural integrity of these vessels and improves their overall performance. The high strength-to-weight ratio of the steel allows for the creation of lighter yet sturdy hulls, enabling ships and submarines to navigate rough seas more effectively. In addition, special steel is extensively used in marine equipment and components. For instance, it is utilized in the manufacturing of propeller shafts, rudders, and other crucial parts that need to withstand the forces exerted by water. Stainless steel, with its corrosion-resistant properties, is ideal for various marine fittings like valves, fasteners, and pipes, guaranteeing longevity and efficient operation in highly corrosive marine environments. Furthermore, special steel finds applications in offshore structures such as oil rigs, platforms, and wind turbines. These structures must endure harsh conditions like strong ocean currents, heavy waves, and corrosive saltwater. Special steel grades like carbon-manganese steel or weathering steel are specifically designed to provide exceptional strength and corrosion resistance, making them suitable for offshore installations. Lastly, in the marine industry, special steel is indispensable for fabricating marine containers and cargo handling equipment. The steel's high tensile strength and impact resistance ensure the safe transportation of goods by sea, making sure that containers can withstand dynamic forces during shipping and protect the cargo from water intrusion. All in all, special steel's unique properties make it an essential material in the marine industry. Its strength, durability, and corrosion resistance significantly contribute to the construction of ships, submarines, offshore structures, marine equipment, and cargo containers, enabling safe and efficient maritime operations.

- Q: How is special steel manufactured?

- Special steel is manufactured through a complex process that involves melting, refining, and shaping steel with precise chemical compositions and desired properties. This may include alloying steel with various elements, such as chromium, nickel, or molybdenum, to enhance its strength, corrosion resistance, or heat resistance. The steel is then formed into desired shapes through techniques like rolling, forging, or casting. The manufacturing process also involves strict quality control measures to ensure the final product meets the specific requirements of various industries, such as automotive, aerospace, or construction.

- Q: What is the role of special steel in sustainable manufacturing?

- Special steel plays a crucial role in sustainable manufacturing by offering enhanced durability, strength, and corrosion resistance, resulting in longer-lasting and more efficient products. It enables the development of lightweight yet robust components, reducing material consumption and energy consumption during production and usage. Additionally, special steel can be easily recycled, contributing to the circular economy and minimizing environmental impact.

- Q: What are the main advantages of using special steel in the construction industry?

- The main advantages of using special steel in the construction industry are its high strength, durability, and resistance to corrosion. Special steel has superior mechanical properties compared to regular steel, allowing for the construction of stronger and more robust structures. It can withstand heavy loads, extreme weather conditions, and natural disasters, ensuring the safety and longevity of buildings. Additionally, its corrosion resistance properties reduce maintenance costs and extend the lifespan of structures, making it a cost-effective choice in the long run.

- Q: What are the main advantages of using special steel in the automotive industry?

- Special steel has several main advantages in the automotive industry. Firstly, it offers increased strength and durability, allowing for lighter weight components without compromising safety. This not only improves fuel efficiency but also enhances overall vehicle performance. Secondly, special steel has excellent corrosion resistance, ensuring a longer lifespan and reducing maintenance costs. Lastly, its versatility enables the production of complex shapes and designs, enabling manufacturers to create innovative and efficient automotive structures.

- Q: What is the fatigue strength of special steel?

- The fatigue strength of special steel refers to its ability to withstand repeated loading or cyclic stress without failure.

- Q: What are the different surface treatments for special steel?

- There are several different surface treatments available for special steel, each serving a specific purpose and offering unique advantages. Some of the most common surface treatments for special steel include: 1. Galvanizing: This process involves coating the steel with a layer of zinc, which provides excellent corrosion resistance. Galvanizing is a popular choice for outdoor applications where the steel is exposed to moisture and harsh environmental conditions. 2. Powder coating: Powder coating involves applying a dry powder to the steel surface, which is then heated and cured to form a durable and protective coating. This treatment offers excellent resistance against corrosion, chemicals, and UV rays, making it ideal for various applications, including automotive parts, appliances, and outdoor furniture. 3. Nitriding: Nitriding is a surface hardening treatment that involves diffusing nitrogen into the steel surface. This process significantly increases the surface hardness, wear resistance, and fatigue strength of the steel. Nitriding is commonly used for high-performance components, such as gears, crankshafts, and injection molding screws. 4. Electroplating: Electroplating involves depositing a layer of metal, such as chromium, nickel, or gold, onto the steel surface through an electrochemical process. This treatment enhances the steel's appearance, provides corrosion resistance, and improves wear resistance. Electroplating is often used for decorative purposes or to enhance the performance of components in various industries. 5. Passivation: Passivation is a chemical treatment that removes iron contaminants from the steel surface, creating a passive oxide layer. This layer acts as a barrier against corrosion, improving the steel's resistance to rust and other forms of degradation. Passivation is commonly used for stainless steel components in industries such as food processing, pharmaceuticals, and medical devices. 6. Carbonitriding: Carbonitriding is a surface treatment that involves introducing carbon and nitrogen into the steel surface at high temperatures. This process forms a hardened case, improving wear resistance and fatigue strength. Carbonitriding is often used for high-stress components, such as gears, crankshafts, and camshafts. These are just a few examples of the different surface treatments available for special steel. The choice of treatment depends on various factors, including the desired properties, application requirements, and budget constraints. It is essential to consult with experts or manufacturers to determine the most suitable surface treatment for specific steel applications.

- Q: How are magnesium alloys used in lightweight structures?

- Magnesium alloys are used in lightweight structures due to their exceptional strength-to-weight ratio. These alloys offer high strength and stiffness while being significantly lighter than other metals like steel or aluminum. This makes them ideal for applications in sectors such as aerospace, automotive, and sports equipment, where weight reduction is crucial without compromising structural integrity. Additionally, magnesium alloys possess good vibration damping properties, corrosion resistance, and excellent machinability, making them even more advantageous for lightweight structure design.

- Q: What is the tensile strength of special steel?

- The tensile strength of special steel can vary depending on the specific alloy and manufacturing process, but it is generally much higher than that of regular steel.

- Q: How does special steel perform in high-temperature hydrogen environments?

- Special steel typically performs well in high-temperature hydrogen environments due to its excellent resistance to hydrogen embrittlement and oxidation. It maintains its mechanical strength and integrity, preventing potential failures or degradation in such conditions. Additionally, special steel alloys can exhibit enhanced corrosion resistance, making them suitable for various industrial applications involving high-temperature hydrogen exposure.

Send your message to us

AISI 1045 Round bar Special Steel Carbon Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords