Special Steel AISI 1010 Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The details of our Steel

1. Produce Standard: as the GB, AISI, ASTM, SAE, EN, BS, DIN, JIS Industry Standard

2. Produce processes: Smelt Iron -EAF smelt Billet - ESR smelt Billet -Hot rolled or forged get the steel round bar and plate

3. Heat treatment:

Normalized / Annealed / Quenched+Tempered

4. Quality assurance:

All order we can received Third party inspection, You can let SGS, BV,.. and others test company test and inspect our products before Goods shipping.

Product information

1.Specification of aisi 1010 steel | ||||||||||||||||

Round bar | Diameter(mm) | Length (mm) | ||||||||||||||

100~300 | 2000~5800 | |||||||||||||||

Plate | Thickness(mm) | Width (mm) | Length (mm) | |||||||||||||

20~70 | 105~610 | 2000~5800 | ||||||||||||||

The specification can be customised! | ||||||||||||||||

2.Chemical compositon of aisi 1010 steel | ||||||||||||||||

NO. | C | Mn | Si | Cr | Cu | Ni | P | S | ||||||||

Aisi 1010 | 0.08~0.13 | 0.30~0.60 | 0.15~0.35 | ≤0.20 | ≤0.25 | ≤0.40 | ≤ 0.50 | |||||||||

DIN1.1191 | 0.42~0.48 | 0.6~0.9 | 0.15~0.35 | ≤0.15 | ≤0.3 | ≤0.2 | ||||||||||

JIS S45C | 0.42~0.50 | 0.5~0.8 | ≤0.40 | ≤0.40 | ≤ 0.4 | |||||||||||

GB45 | 0.42~0.50 | 0.5~0.8 | 0.17~0.37 | ≤0.25 | ≤0.25 | ≤0.3 | ≤0.035 | ≤0.035 | ||||||||

3. Mechanical properties of aisi 1010 steel | ||||||||||||||||

Annealing | Forging | Tempering and Hardening | Normalization | |||||||||||||

Subcritical annealing: 650~700 Isothermal annealing: 820~860 | 1100~850 | Tempering: 550~660 Hardening : 820~860 water | 840~880 | |||||||||||||

Main product

High speed steel | |

AISI | M2,M4,M35,M42,T1 |

DIN | 1.3343,1.3243,1.3247,1.3355 |

JIS | SKH51,SKH54,SKH35,SKH59,SKH2 |

Cold work tool steel | |

AISI | D2,D5,D3,D6,A8,A2,O1 |

DIN | 1.2379,1.2601,1.2080,1.2436,1.2631,1.2363,1.2510,1.2327 |

JIS | SKD10,SKD11,SKD1,SKS3 |

Hot work tool steel | |

AISI | H13,H11,H21 |

DIN | 1.2344,1.2343,1.2367,1.2581,1.2713 |

JIS | SKD61,SKD6,SKD7,SKD5SKT4 |

Plastic mould steel | |

AISI | P20,P20+Ni,420 |

DIN | 1.2311,1.2738,1.2083,1.2316 |

JIS | PDS-3,SUS420J1,SUS420J2 |

Alloy structural seel | |

AISI | 5140,4340,4135,4140 |

DIN | 1.7035,1.6511,1.7220,1.7225 |

JIS | SCr440,SNCM439,SCM435,SCM440 |

Stainless steel | |

AISI | 440C,420,430 |

DIN | 1.4125 |

JIS | SUS440C |

Carbon steel | |

AISI | 1045,1020 |

DIN | 1.1191 |

JIS | S45C, G3101 |

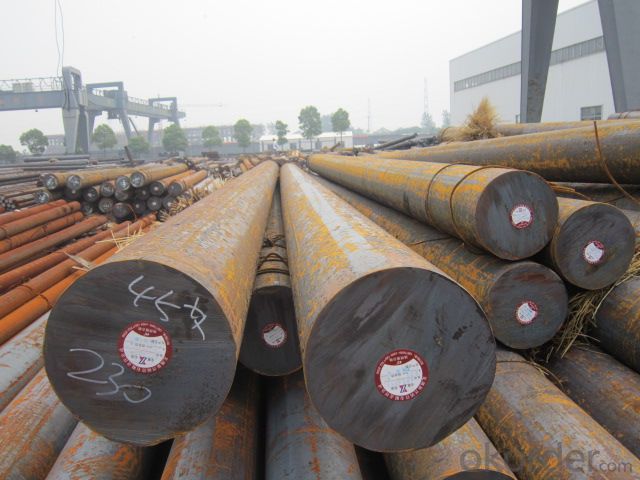

Product show

Workshop show

Shipping

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

Payment Terms

1.Payment: T/T, L/C, Western Union, MoneyGram,PayPal; 30% deposits; 70% balance before delivery.

2.MOQ: 1pcs

3.Warranty : 3 years

4.Package Informations: 1) EXPORT, In 20 feet (GW 25 ton) or 40 feet Container (GW 25 ton)

2)as customer's requirement

Why choose us?

(1) The leading exporter in China special steel industry.

(2) Large stocks for various sizes, fast delivery date.

(3) Good business relationship with China famous factories.

(4) More than 7 years steel exporting experience.

(5) Good after-sales service guarantee.

- Q: Can special steel be used in the furniture manufacturing industry?

- Yes, special steel can be used in the furniture manufacturing industry. It provides strength, durability, and flexibility, making it suitable for various furniture components such as frames, legs, and hardware. Special steel alloys can also offer unique aesthetics and design possibilities, contributing to the overall quality and appeal of furniture products.

- Q: What are the different types of high-speed steel?

- There are several different types of high-speed steel, including M1, M2, M42, and T1. Each type has its own unique composition and properties, making them suitable for various applications in cutting tools, drills, and machining operations.

- Q: How is special steel used in the production of turbine blades?

- Special steel is used in the production of turbine blades due to its exceptional strength, heat resistance, and corrosion resistance properties. This high-quality steel allows turbine blades to withstand the extreme conditions within a turbine, including high temperatures and rotational speeds. Additionally, the unique composition of special steel enables the blades to maintain their shape and structural integrity, ensuring optimal performance and longevity in power generation applications.

- Q: What are the different types of tool steel?

- There are several types of tool steel, including high-speed steel, cold work steel, hot work steel, and shock-resisting steel. Each type is specifically designed for different applications and has unique properties to withstand various conditions and demands. High-speed steel, for example, is known for its ability to retain hardness at high temperatures, making it suitable for cutting tools. Cold work steel is used for applications involving cutting, shearing, and forming metals at lower temperatures. Hot work steel, on the other hand, is designed to withstand high temperatures and is commonly used in die casting and forging. Lastly, shock-resisting steel is used in applications where the tool is subjected to high impact or sudden shocks, such as in chisels or hammers.

- Q: How is nitriding steel used in surface hardening processes?

- Nitriding steel is used in surface hardening processes by introducing nitrogen into the surface layer of the steel through a controlled heat treatment. This process enhances the hardness, wear resistance, and fatigue strength of the steel, making it more durable and suitable for applications that require high surface hardness and improved performance.

- Q: What is the process of manufacturing special steel?

- To produce high-quality and durable special steel with specific properties, several steps must be taken in the manufacturing process. Firstly, the raw materials needed for special steel production, such as iron ore, coal, chromium, nickel, and manganese, are selected meticulously based on the desired properties of the final product. Once the raw materials have been chosen, they are melted in large furnaces, either through the use of electric arc furnaces or basic oxygen furnaces. These furnaces subject the raw materials to extremely high temperatures, transforming them into molten metal. After the raw materials have been melted, the molten metal undergoes a refining process to eliminate any impurities. Techniques such as degassing, desulphurization, and deoxidation are employed to ensure that the steel is free from unwanted elements that could have a negative impact on its properties. Next, alloying elements are added to the molten metal after the refining process to achieve the desired properties. The proportion and specific alloying elements utilized depend on the intended application of the special steel. The molten steel is then poured into a continuous casting machine, which solidifies it into semi-finished products known as billets, blooms, or slabs. This continuous casting process guarantees a consistent and uniform structure throughout the steel. The semi-finished products are reheated and passed through a series of hot rolling mills. This process involves reducing the thickness and shaping the steel into various forms, including bars, rods, plates, or sheets, depending on the intended use. Following hot rolling, the steel may undergo heat treatment processes like annealing, quenching, tempering, or case hardening. These treatments further enhance the mechanical properties of the steel, such as its hardness, toughness, and ductility. The final step involves surface finishing and quality control measures. The steel is thoroughly inspected for any defects or imperfections that may have occurred during the manufacturing process. Surface treatments like pickling or galvanizing can also be applied to enhance the steel's appearance and protect it from corrosion. In conclusion, manufacturing special steel is a complex and precise operation that involves careful selection of raw materials, melting, refining, alloying, continuous casting, hot rolling, heat treatment, and finishing. These steps ensure that the resulting steel meets the specific requirements and performance characteristics demanded by various industries.

- Q: How does special steel perform in chemical processing applications?

- Special steel is highly desirable in chemical processing applications due to its excellent corrosion resistance, high temperature resistance, and strength. These properties allow it to withstand harsh chemical environments and maintain its structural integrity, ensuring safe and efficient operation. Additionally, special steel can exhibit exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking, making it an ideal choice for various chemical processing equipment such as reactors, storage tanks, and pipelines.

- Q: What are the specific requirements for special steel used in the chemical reactor industry?

- The specific requirements for special steel used in the chemical reactor industry typically include high corrosion resistance, excellent heat resistance, and strong mechanical properties. It should also have the ability to withstand aggressive chemical environments, such as strong acids or alkalis. Additionally, the steel should have low levels of impurities to prevent contamination of the chemical reactions.

- Q: What are the main advantages of using special steel in the construction of bridges?

- The main advantages of using special steel in the construction of bridges are its high strength, durability, and resistance to corrosion. Special steel, such as high-strength low-alloy steel or weathering steel, can withstand heavy loads and extreme weather conditions, making it ideal for bridge construction. Its superior strength allows for the design of lighter and more cost-effective structures. Additionally, special steel's resistance to corrosion reduces maintenance and repair costs, ensuring the longevity and safety of the bridge.

- Q: What are the casting methods for special steel?

- There are several casting methods used for special steel, including the traditional sand casting method, investment casting, and continuous casting. Each method has its own advantages and is chosen based on factors such as the complexity of the steel shape, desired surface finish, and production volume.

Send your message to us

Special Steel AISI 1010 Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords