Agru Geomembrane Geocomposite for Landfill Wastewater Prevention

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

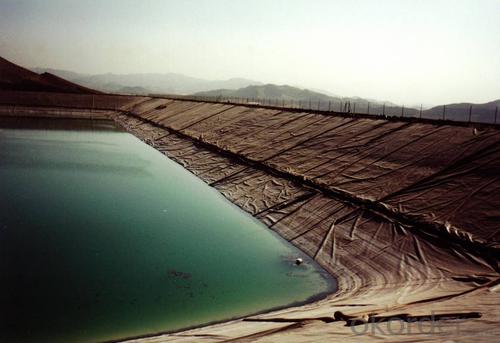

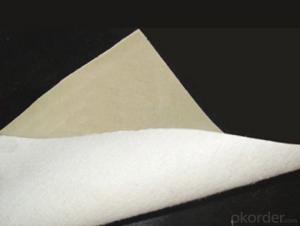

Structure of Geocomposite Membrane for Landfill

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

Main Features of Geocomposite Membrane for Landfill:

Environmental Engineering: Landfill,Sewage treatment plant, Electric plant regulating reservoir, Hospital solid waste, etc.

Hydraulic Engineering: Canal waterproof, Dam leaking stoppage, reinforcement, Vertical core, Slope protection, Revetment, etc.

Municipal Engineering: Tunnel, Subway, Planted roof, Roof garden,Sewage conduit lining, etc.

Gardens Engineering: Artificial Lake, Watercourse, Impounding reservoir, Golf course pond lining, Lawn waterproof, etc.

Geocomposite Membrane for Landfill Images

Geocomposite Membrane for Landfill Specification :

No. | Item | Test Value | |||||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | |||||

1 | Minimum Density(g/cm³) | 0.939 | |||||||||

2 | Tensile Property | ||||||||||

Yield Strength ,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||||

Break Strength ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | ||||

Yield Elongation ,% | 12 | ||||||||||

Break Elongation ,% | 700 | ||||||||||

3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | |||

4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | |||

5 | Stress Crack Resistance, hrs | 300 | |||||||||

6

| Carbon Black | ||||||||||

Carbon Black Content, % | 2.0-3.0 | ||||||||||

Carbon Black Dispersion | Carbon black dispersion(only near spherical agglomerates) for 10 different views 9 in categories 1 or 2 and 1 in category 3 | ||||||||||

7

| Oxidative induction time(OIT) | ||||||||||

Standard OTI Min | 100 | ||||||||||

High Pressure OTI Min | 400 | ||||||||||

8 | Oven aging at 85℃ | ||||||||||

Standard OIT-% retained after 90 days | 55 | ||||||||||

High pressure OIT-% retained after 90 days | 80 | ||||||||||

9 | UV Resistance | ||||||||||

Standard OIT retained after 1600 hrs | 50 | ||||||||||

High pressure OIT retained after 1600 hrs | 50 | ||||||||||

10 | Low tempreture impact brittle property at -70°C | Pass | |||||||||

11 | Water vapor permeability (g.cm/cm2 .s.Pa) | ≤1.0×10-13 | |||||||||

12 | Dimensional Stability (%) | ±2 | |||||||||

FAQ:

1. How about the delivery time?

Two weeks upon receipt of down payment.

2. What kind of payments do we accepted?

T/T, L/C, WesternUnion, MoneyGram.

3. What's are the MOQ?

Normally the MOQ is 5000 SQM in theory.

And we can provide you free samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee in your second order.

5. Can you produce the product according to customers' requirements?

Sure, we are professional manufacturer, OEM and ODM are both welcome

- Q: What is the diatomite craft?

- The purpose of diatomite beneficiation is to remove the impurities including mud, debris, iron and aluminum to realize enrichment of diatom. General method is gravity milling, divided into dry and wet types. Dry separation is to remove gangue with air separator or remove organics, volatile matter and water with rotating dryer, mainly used for high grade ore. While wet separation is to remove larger density gangue impurities with hydrocyclone, mainly used for low grade ore;

- Q: Is it worthwhile to stick membrane for high-end mobile phone?

- It is worthwhile for common cellphone but not for high-end mobile phone. The film for high-end mobile phone will be better than that of common mobile phone. But when sticking film, you need to see the cellphone material. Some mobile phone does not need to stick film, not to say that the high-end mobile phone film.

- Q: Can geomembranes be used in fishpond lining?

- Yes, geomembranes can be used in fishpond lining. They are often used as a waterproof barrier to prevent leakage and seepage in fishponds, ensuring the containment of water and maintaining the desired water level for fish farming.

- Q: What are the considerations for geomembrane installations in high-wind areas?

- When installing geomembranes in high-wind areas, several considerations need to be taken into account. Firstly, the selection of a suitable geomembrane material with a high tensile strength and resistance to tearing is crucial. The installation techniques should also be tailored to withstand strong winds, which may involve using additional anchoring methods, such as ballasting or mechanical fastening, to ensure the geomembrane remains securely in place. Furthermore, the design of the geomembrane system should consider wind load calculations, taking into consideration factors such as wind direction, duration, and gustiness. Regular inspections and maintenance should be conducted to identify and address any potential wind-related damage or stress on the geomembrane. Overall, a comprehensive understanding of the site-specific wind conditions and the appropriate design and installation measures are essential for a successful geomembrane installation in high-wind areas.

- Q: How much is PVC composite geotechnical membrane?

- Geomembrane is widely used in canal leakproof project. In recent years, the applications of geosynthetics in civil engineering, particularly, a large number of applications and effectiveness in flood rescue project, have arroused high attention of the majority of engineering and technical staff. For application technology of geosynthetics, the country has put forward normative technical requirements from seepage, filtration, drainage, reinforcement, protection and other aspects, which has accelerated the pace of the popularization and application of new materials. The material is widely used in seepage-proof projects in canals. I will give a brief account of application technology of geomembrane combined with the construction practice.

- Q: How are geomembranes inspected for damage or leaks?

- Geomembranes are inspected for damage or leaks through various methods such as visual inspections, leak detection surveys, and non-destructive testing techniques. Visual inspections involve physically examining the geomembrane surface for any visible signs of damage or punctures. Leak detection surveys utilize specialized equipment like electronic leak locators, which can detect leaks by sensing changes in electrical conductivity or potential difference across the geomembrane. Non-destructive testing techniques, such as vacuum box testing or air lance testing, can also be employed to identify leaks by creating pressure differentials and observing any air or water bubbles indicating leakage. These inspection methods help ensure the integrity and functionality of geomembranes in various applications.

- Q: the using method of Film thickness gauge ?

- This instrument is widely used in manufacturing, metal processing industry, chemical industry, commodity inspection and other testing fields. it is the necessary equipment for the material protection. Magnetic measuring mechanism method, when the probe is in contact with the cladding, the probe and the magnetic metal substrates constituting a closed magnetic circuit, due to the presence of a non-magnetic coating, the magnetic resistance changes, by measuring the amount of change we can obtain the thickness of the coating.

- Q: Are geomembranes compatible with other materials used in construction?

- Yes, geomembranes are compatible with other materials used in construction. They can be easily integrated with various construction materials such as concrete, soil, rocks, and steel. Geomembranes are flexible and adaptable, allowing for seamless compatibility and effective performance in construction projects.

- Q: What is the geomembrane material?

- Function: anti-seepage, isolation Product use: geotechnical dam, rockfill dam, masonry dam and pressure concrete dam; dike, dam front level anti-seepage cover, vertical foundation impervious layer; tailings dam, Roads, highways, railway subgrade; roadbed and other ground salt control; expansive soils; roadbeds, reservoirs (pit, kangang); waste land; subway, basement and tunnel, tunnel seepage lining; And waterproof layer of collapsible loess; roof leakage.

- Q: How do geomembranes prevent seepage and leakage?

- Geomembranes prevent seepage and leakage by acting as a barrier between fluids, such as water or chemicals, and the surrounding environment. These synthetic liners are impermeable and resistant to punctures, corrosion, and degradation. When installed correctly, geomembranes create a reliable and durable barrier that prevents fluids from permeating through the underlying soil or rock, effectively containing them within the desired area.

Send your message to us

Agru Geomembrane Geocomposite for Landfill Wastewater Prevention

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords