A Light Weight Lightgage Steel Joist For Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Specifications

Lightgage Steel Joist

1.Material: Galvanized Steel

2.Accept Customization

3.Free Sample Offer

4.Promptly delivery

Lightgage Steel Joist

2,Details

1) Material: galvanized steel

2) Zinc coating: from 100~275g per square meter

3) Yield strength 400mpa.

purlin and wall beam of steel structure building

The C-shaped purlins have excellent anti-bending property and are easy to install. They are widely used as the supporter of roof and wall in large-scale and mid-scale construction, such as factory, warehouse, garage, exhibition center, cinema, theatre, garden and so on.

Advantage:

(1). Design according to customers’ requirements

(2). Manufacture under complete quality control system---ISO9001

(3). Installation with instruction of experienced engineers

(4). Easy to assemble and dismantle

(5). Eco-friendly material: can be used for several times and can be recycled

(6). Shorter construction period, longer using time

(7). High strength and stiffness, high weight bearing.

3.Image

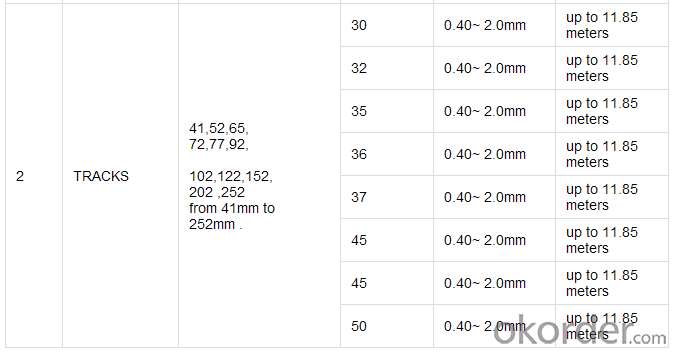

4.Detailed Specification

5.FAQ

1) Light steel structure

2) Color steel sandwich panel(EPS) panel for roof and wall

3) Color steel sandwich panel has a good fire proof and heat insulation

performance for the characteristic of the color steel sheet and polystyrene material.

4) The material of doors and windows are plastic steel

5) Easy to assemble and disassemble for several times without damage

6) Cost saving and transportation convenient

7) Anti-rust and normally more than 10 years using life

8) The house resistance to typhoon of force 12 degree, resistance to earthquake of force 7 degree

- Q: Decoration light steel keel ceiling in the side of the keel main keel vice keel What is the meaning?

- The main keel is generally carrying keel, vice keel is connected to carry keel and gypsum board, while the keel is used in the wall around to fix the main keel

- Q: Ceiling light steel keel specifications are models which several

- Wall keel main specifications are divided into Q50, Q75, Q100 and Q150. Ceiling keel main specifications are divided into D38, D50 and D60 and so on. According to their cross-sectional shape is divided into U-type, C-type, T-type, H-type, V-type, L-type, CH-type seven, light steel keel mark the order: product name, code, cross-sectional shape of the width, Thickness and standard number. Customers should be based on process and decoration requirements, decided to use the wall keel, ceiling keel and specifications and cross-sectional shape.

- Q: Is this a ceiling that can be built? Use light steel keel gypsum board or wood keel? Trouble in detail under the construction process

- With light steel keel with three or four to mention the mention of the shape of it! Absolutely solid!

- Q: Tectonic hierarchy of light steel keel

- Main machine The main equipment includes: saws, toothless saws, nail guns, hand saws, hand plane, pliers, screwdrivers, moving, square feet, steel ruler, steel level and so on.

- Q: Light steel keel ceiling price 60 level probably need much money

- Gypsum board or aluminum plate or mineral wool board. The Up to 7000 or less. Minimum of 4000 or less

- Q: Light steel keel ceiling price is not expensive?

- Light steel keel 45 yuan package package materials, light industry 15 yuan, silicon calcium board package package materials 20 yuan light industry 10 yuan

- Q: Light steel keel ceiling hidden information, including what ah

- Electrical wiring, electric pipe threading and other electrical professional projects have been done;

- Q: Ecological wood veneer gypsum board closed light steel keel ceiling decoration drawings so what is the meaning? How to understand

- The above is just speculation in accordance with the practice only, the designer belongs to the garbage family, did not see such a "note". It is recommended to consult the designer, be confirmed, so as to avoid mistakes.

- Q: Light steel keel ceiling installation detailed process

- Light steel keel: With the level of the room in each corner of the wall to copy the level of the point, pop the horizontal line, with the amount of water to the ceiling design height plus a layer of thickness, with powder line along the column pop-up line, that is, Down line. At the same time, according to the ceiling plan in the concrete roof pops up the position of the main keel, the main keel should be from the center of the ceiling to the two points, the maximum spacing of 1000mm, and marked the boom of the keel should be from the ceiling to the two points, and marked the fixed point of the boom, The fixed point spacing of the boom is 900-1000mm. If the fixed point of the beam and pipe is larger than the design and procedure requirements, the fixed point of the boom should be increased.

- Q: Light steel keel paper gypsum board ceiling construction process

- 1. Process: Slide - → Install the big keel boom - → install the big keel - → install the keel - → install the keel - → install the cover cotton board - → install the pressure bar - → brush anti-rust paint 2. Pin line: According to the floor elevation line, with the ruler vertical volume to the top [shed design elevation, along the wall, the column around the ceiling height, and along the elevation of the ceiling line, draw a good line on the wall line. 3. Install the big keel boom: After playing the high level of the ceiling and the keel position line, determine the elevation of the lower end of the boom, press the big keel position and the hanging spacing, the boom without the end of the screw thread and the floor embedded rib Connection is fixed.

Send your message to us

A Light Weight Lightgage Steel Joist For Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords