Ceiling Profile C Channel & U Steel Channel for Office Partition Wall

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Lightgage Steel Joist

Features of light steel joist: high performance, easy cut apart, non-deforming, simply installation, dry construction, light weight and environment friendly.

Method to test the keel's quality

1. look. Appearance smooth, no spots.

2. galvanized thickness: 80g/m2( qualified), 100g/m2( A grade), 120g/m2 ( A+ )

We are a manufacturer of steel keel with well-equipped testing equipment and strong technical force.

With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in decoration and other industries.

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs.

We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

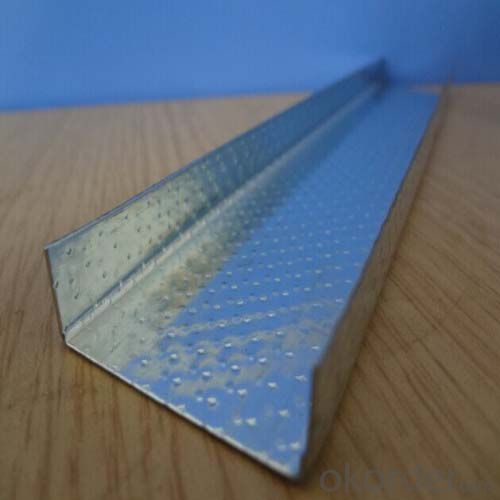

3.Image

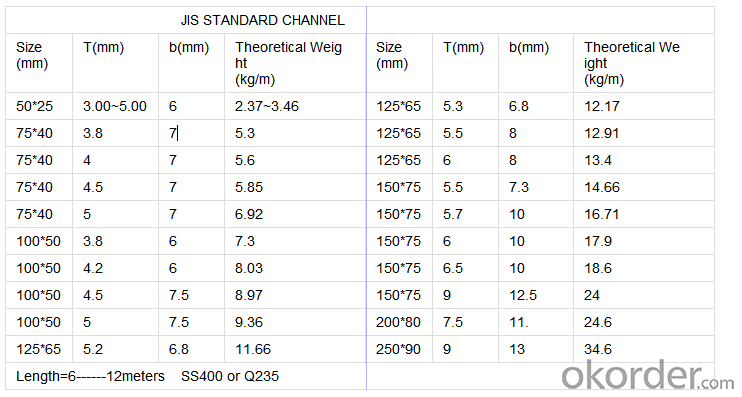

4.Detailed Specification

5.FAQ

zinc galvanized steel strip :

(1)Standard: ASTM, JIS

(2)Steel Grade: Q195

(3)Width :600mm-1500mm

(4)Surface:galvanized or Zinc

Packaging & Delivery

Hot rolled galvanized steel strip

1. thickness: 0.18mm - 1.5mm

2. width: 20mm - 580mm

3. material: Q195, Q195L, Q235

4. Origin of China

5. Package: export seaworthy packing

6. Galvanized or zinc

7. coil weight: 100kg-1000kg /coil

8. around 25 tons can be loaded in 1x20'FCL.

9. slit edge or mill edge.

10. Any third party inspection can accept.

- Q: Light steel keel ceiling which brand is better

- You can go to the forum to consult the other owners to see everyone's views

- Q: Toilet integrated ceiling with good or good light steel keel good

- Of course the light steel keel is good. Wood keel gradually not used in the bathroom, the ceiling is not ventilated, a long time will be wet moldy. Reminded one, many brands of multi-grade ceiling, to their own to compare the choice of different stores.

- Q: What kind of material is better for some kind of ceiling, such as wood keel, light steel keel, or

- After the line with the woodworking board to open about 200mm wide oval frame (upper and lower layers) and then use 200 * 400 (height) of the wood plate around the oval to do the upper and lower layers of the two oval connected inside and then sealed 5mm board plate Hang up to shape out (drawing very good description of the painting really can not say you do not know clearly)

- Q: 38 light steel keel standard thickness is how much? Built-in 38 light steel dragon thickness to achieve how much to meet the requirements?

- 38 keel of the national standard thickness is 0.8mm. Positive and negative tolerances are generally 0.02-0.03mm The width is 38mm. Should look for light steel keel information point of view. You do not seem to understand it at all. Light steel keel called 38.50.75.100 .. The The Is their width. GB height is 10mm. Length is customizable. Generally 3m and 4m. In addition, the minimum standard of the ceiling keel should be 50 of the main keel. If it is to do 600 * 600 decorative ceiling. 38 GB can also be. Do the ordinary gypsum board ceiling 38 models are also insufficient. Affect the quality of the project.

- Q: Is this a ceiling that can be built? Use light steel keel gypsum board or wood keel? Trouble in detail under the construction process

- This program is too rigid. The original is the pattern of the ground parquet. ... ... If you want to do the sky, then the outer circle with a splint, the middle floor with a grid (optional aluminum grille or wooden side) parquet can be used to clamp two decorative panels or fire, or then parquet with the top of the plywood Different colors of ICI

- Q: Light steel keel gypsum board ceiling technology

- Surface layer putty, brush paint, lamps and other calculations.

- Q: Attic light steel keel gypsum board ceiling construction drawings how to draw?

- To draw one or several sections, to express the steeple tilt angle and internal structure (light steel keel plus gypsum board) on the line

- Q: Play light steel keel cut off how not to damage the ceiling

- If the existing ceiling is gypsum board, there must be keel in the top

- Q: Now decoration light steel keel 600X600 mineral wool board (ordinary) ceiling how much money a square meter?

- Package workers a square meter twenty yuan or so, Bao Gong Bao material will be about a square meter 70 yuan,

- Q: Which is more cost-effective, want to get a professional answer Oh, anxious decoration it

- Certainly light steel keel wood keel is not fire waterproof

Send your message to us

Ceiling Profile C Channel & U Steel Channel for Office Partition Wall

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords