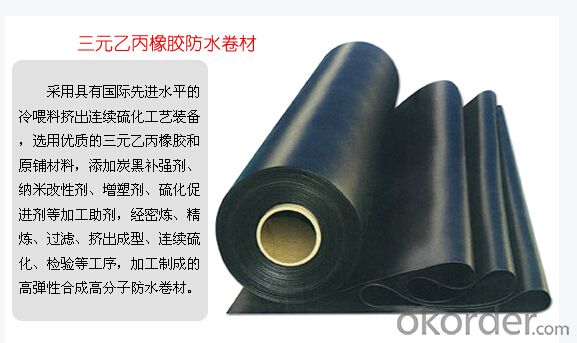

A Grade Quality EPDM Waterproofing Membrane for Roof Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Specification for EPDM Waterproof Membrane:

There are two installation ways.one is full sticking,the other is hot welding.

Type | EPDM Waterproof Membrane | |||

Material | EPDM Rubber | |||

Thickness | 1.0mm | 1.2mm | 1.5mm | 2.0mm |

Size | 1.2m(width) * 20m(length)/roll | |||

Type | Vulcanized | |||

Pattern | Non-reinforced(homogeneous) | |||

Packing | 24sqm--80sqm/roll, with plastic bag | |||

Color | Black | |||

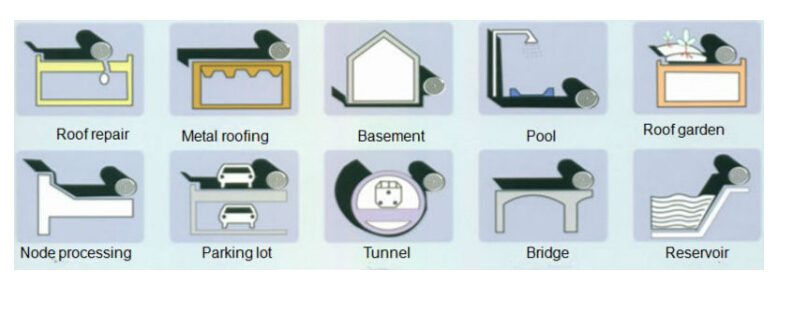

Application | Roofs, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | |||

2.Product Technicial Data for EPDM Waterproof Membrane:

No. | Item | Technical index | ||

JL1 | JF1 | |||

1 | Tensile strength at break Mpa | Normal temperature≥ | 7.5 | 4.0 |

60°C≥ | 2.3 | 0.8 | ||

2 | Elogation at break | Normal temperature≥ | 450 | 400 |

-20°C≥ | 200 | 200 | ||

3 | Tearing strength KN/m≥ | 25 | 18 | |

4 | Impermeability 30minutes No leak | 0.3Mpa | 0.3Mpa | |

5 | Low temperature flexibility °C≤ | -40 | -30 | |

6 | Heat air ageing 80°C x 168h | Tensile strength retention rate % ≥ | 80 | 90 |

Elogation retention rate % ≥ | 70 | 70 | ||

Apperance of 100% elogation | no crack | no crack | ||

3. Product Application:

a. Make sure the base surface smooth, clean and dry(Moisture<9%), then paint the delicated agent on the base surface. Start application till it is dry.

b. Reinforce the parts which are easy to leak, such as seam, hole, channel, wall, pipe and corner.

c. Application Method:

Lay the membrane directly. Be careful to control the overlaps of the long side and short side.

d. After application, a careful inspection is required. Make sure there is no air bubble, no fold, no falling away etc to guarantee the waterproof life.

4. Some photos:

- Q: SBs waterproof cold sticky how to do?

- 2, brushing the primary treatment agent. To enhance the adhesion of the web and the base layer, should be applied at the grass-roots level treatment agent (usually brush 2 cold base oil), brushing to be uniform, do not repeatedly brushing.

- Q: Is a waterproofing membrane resistant to solvents or chemical spills?

- Yes, a waterproofing membrane is typically resistant to solvents or chemical spills. Waterproofing membranes are designed to provide a protective barrier against water and other liquids, including solvents and chemicals. These membranes are often made of materials such as PVC, TPO, or EPDM, which have excellent resistance to various solvents and chemicals. However, the specific resistance may vary depending on the type and composition of the membrane. It is always recommended to check the manufacturer's specifications and consult with professionals to ensure the membrane's compatibility with specific solvents or chemicals before installation.

- Q: Does a waterproofing membrane affect the appearance or finish of a surface?

- Yes, a waterproofing membrane can affect the appearance or finish of a surface.

- Q: What are the requirements for frost resistance of basement floor polymer waterproofing membranes?

- Sbs elastomer modified asphalt membrane is -25 degrees,

- Q: Can a waterproofing membrane be used on tunnels with security systems?

- Yes, a waterproofing membrane can be used on tunnels with security systems. In fact, it is highly recommended to use a waterproofing membrane in tunnels, especially those with security systems, to protect the infrastructure and valuable equipment from water damage. Waterproofing membranes are designed to prevent water infiltration, providing a protective barrier against water leakage and potential moisture-related issues such as corrosion, mold growth, and structural deterioration. By using a waterproofing membrane in tunnels with security systems, the integrity of the tunnel structure and the functionality of the security systems can be preserved, ensuring the safety and security of the facility.

- Q: Can a waterproofing membrane be installed by a homeowner or is professional installation required?

- Professional installation is typically recommended for waterproofing membrane installation. This is because it involves complex techniques and specialized equipment that homeowners may not have. Additionally, professionals are trained to assess and address specific waterproofing needs, ensuring a more reliable and effective installation.

- Q: Can a waterproofing membrane be used in conjunction with drainage systems?

- Yes, a waterproofing membrane can be used in conjunction with drainage systems. The membrane provides a barrier to prevent water penetration, while the drainage system helps to channel and remove any water that may accumulate. This combination ensures effective and comprehensive waterproofing for various applications such as basements, roofs, and underground structures.

- Q: Is a waterproofing membrane resistant to punctures or tears?

- Yes, a waterproofing membrane is designed to be resistant to punctures and tears. It is specifically engineered to provide a durable barrier that can withstand potential damage from sharp objects or external forces.

- Q: Can a waterproofing membrane be used for green roofs?

- Yes, a waterproofing membrane can indeed be used for green roofs. Waterproofing membranes are commonly used as a crucial layer in green roof construction to prevent water leakage and protect the underlying structure. It provides an effective barrier against water infiltration, ensuring the green roof system remains watertight and preserving the integrity of the building.

- Q: Can a waterproofing membrane be used for a planter box wall?

- Yes, a waterproofing membrane can be used for a planter box wall. The membrane will help to prevent water from seeping into the wall, which can cause damage over time. Additionally, it will also help to protect the wall from moisture-related issues such as mold or mildew.

Send your message to us

A Grade Quality EPDM Waterproofing Membrane for Roof Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords