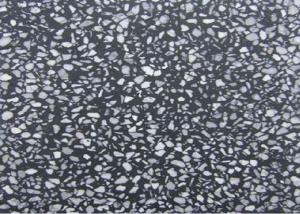

85% Microsilica Concrete Admixture

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Tons m.t.

- Supply Capability:

- 3600 Tons per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1.85% Microsilica -concrete admixture

2.Stable quality

3.high tempreture to 1600 degree

4.good activity indicators

Technical Data:

Parameters | Standard Value |

Silicon Dioxide(SiO2) | min 85 % |

Loss on Ignition(L.O.I) @ 975°C | max 4 % |

Moisture Content | max 3 % |

Percent Retained On 45μm (325 sieve) | max 2 % |

Bulk Density | 600-700kg/m3 |

Microsilica CAS #: 69012-64-2

Microsilica Packing: 900kg/jumbo bags and 25kg small plastic woven bags.

- Q: I'm considering using hydraulic cement to stop my basement from leaking, We would like to finish it someday but want to make sure it won't leak later and cause more problems. Is it better to apply to the inside wall of the foundation or to dig around the house and apply to the outside? We don't have any obvious huge cracks that we've seen yet. Has anyone used hydraulic cement and have any tips/advice? Any help would be appreciated! Thanks!

- There is nothing magic about hydraulic cement in terms of trying to stop a leak. It is really used as a no shrink cement for anchoring posts, anchor bolts, etc into concrete. You need to determine exactly where the water is coming from and deal with it. You may have a severe ground water problem, poor drainage, or other causes.

- Q: Which type of cement

- portland cement, 3 parts gravel 2 parts sand 1 part cement just enough water to make a paste

- Q: which are the top brand cement in India, Top to Bottom?

- The top brand of cement in india are: 1. Ultra tech 2. Jaycee 3. Ambhuja 4. Shree Ultra 5. JK Super cement 6. Binani 7. Bhangur 8. Birla Chetak 9. Acc Cement and so on....

- Q: stop dog from pooping in backyard cement walkway where kids come and go we try to show him where theres a corner of dirt by our trash cans , he went there once only

- I'm sorry, after all the 'my dog poops all over the house' questions, this just strikes me as hilarious! Maybe some of those people that can't seem to get their dog to poop in the backyard at all can help you out! LMAO! Seriously though, you were doing the right thing with taking her on a leash and using praise and treats, it's just going to take longer to really get the dog to understand that this is where it needs to go. Just give it more time. When the dog starts to lead you to that spot, you'll know she has it down and doesn't need the leash anymore.

- Q: Make the yard with cement is cheaper or brick is cheaper? thanks!?

- Get contractor estimates for both. Cement is a lot of manual labor, but the materials will be cheaper. Brick is the other way around. Good luck! We are in the middle of our own extensive backyard remodeling, and found that the cost of materials will vary greatly depending on your locale and how far the materials have to be transported. I'd shop around a couple local garden supply stores, and then get estimates for the labor from contractors. If you don't know the price of your materials, contractors are likely to inflate the prices if they procure them for you.

- Q: Okay, I have some 4quot;PVC to 2quot;PVC reducer, a 4quot; PVC tank/endcap, and a ball valve. It is going to be under a lot of pressure (70-100PSI), this is my first time bonding PVC so what should i do in steps? I heard PVC Primer then Cement it together. Anything else?

- Make sure your reducer (as well as other parts) are NOT Drain/Waste/Vent, as they are not rated for that much pressure. The main difference is how deep the socket(female) is. If it is about 1/2 inch on the 2 inch side, it won't hold that much pressure. 1/4 turn is all that's needed, and hold for about 15 seconds. Wipe off any excess. It doesn't hurt anything, the glue bonds by melting the PVC, and it will reharden.

- Q: I had the foundation repaired in my basement a while back and the dust from the cement is still there, I've washed the floor about 5 times since and it still hasn't come off, got any suggestions about what I should do?

- The cement is doing what it should. A previous questioner had trouble with the concrete floor in his garage. He spilt some vinegar on the floor and found it had eaten the surface the next day. If you can convince your wife to let you have some for an experiment ??? Beware vinyl stained by vinegar and swapping one problem for another. GL>

- Q: The wind knocked over part of our wood fence. Two of the wood posts that were cemented into the dirt were uprooted. I figure the best way to fix the fence would be to use new posts (or bust off the old cement) and bury them in the ground with fresh cement. I'm feeling lazy and wonder if I do as good of a job just burying the old posts with the old cement back into the ground. Will it hold? Maybe this is a no-brainer for some folks - useful comments appreciated.

- Plywood will rot. Build a form out of 2 X 4's or 2 X 6's around the whole thing and then put an inch cap over the whole thing. Then this in turn will fill the hole and you will have a nice flat surface. If you want to patch it you have to take the old concrete out that is lose all the way to the subgrade then pour a patch but doing this you will still allow a small seam to allow moistuire to get in if it freezes it will pop it up. So the best thing to do is to add a lip of one inch above the whole thing. You will also have to break lose any loose concret e and remove before doing the whole lip. Also put a broom finish on top and this will allow moisture to run off of the concrete.

- Q: We're casting cement for testing, and we're not sure about how to calculate for the quantities. We're using a 15.24 cm diameter and 30.48 cm tall mould. We're using a water-cement ratio of 1:2, and a cement-sand-gravel ratio of 1:3:3. We're not sure how to calculate how much of everything we need, and we need the specific quantities for our methodology. Can anyone help?

- Total volume of the mould is pi r^2 h = 3.14159 (30.48) (15.24)^2 cm^3 = 22240 cm^3 The usual practice is to dry-blend the solids before adding the water, but I'm going to assume you really mean that the water amount is 1/2 the cement amount (not 1/2 the amount of total solids). You really need only enough water to make the mixture workable, but if 1/2 the cement is the correct amount of water, then the needed quantities are water 22240/15 = 1483 cc = 1.483 liters cement 44480/15 = 2965 cc (dry) sand 44480/5 = 8896 cc gravel 44480/5 = 8896 cc total = 22240 cc Probably best to mix up a bit extra of all the dry stuff in case the amt of water needed turns out to be less than you think.

- Q: I am looking forward to building a block fence. I ran into a YouTube video on the Quikwall surface bonding cement and was curious on your thoughts about that product. Have you tried it? On what and what do you think about it? Thanks!

- Hello Monika, Surface bonding cement can be a good construction technique. I like the ability to adjust the blocks until the bond beam or the stucco is applied. For me this has always been easier than setting each block in a mortar bed. Quikwall is the most prominent product of the surface bonding cements but I don't believe it is the best. I have had customers across the country report mixed results with it. Sometimes it has been outdated bags other times it looks like the product has been leaned out as much as possible for value engineering. Lately I have been suggesting to people to use any premium product other than Quikwall. There are several brands across the country. Mixing any SBC correctly is very important. If you can use a small mortar mixer it will work better than hand mixing. Another option for fencing that I have seen is to do the dry stack block and then fill several of the cores like a regular block wall. With this approach people often save money by using fibered stucco over the blocks because they don't need all of the structural fibers or waterproofing additives in the SBC mix..

Relying on many years of a good reputation and good service, we have many customers from at home and abroad. We have established long-term and steady business relationship with them. Our Microsilica products are not only selling well in China, but also exported to the United States, Germany, Australia, Asia, and other countries and regions around the world.

1. Manufacturer Overview

| Location | Luoyang, Henan, China (Mainland) |

| Year Established | 2011 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Oceania; Mid East; Eastern Asia |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

85% Microsilica Concrete Admixture

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Tons m.t.

- Supply Capability:

- 3600 Tons per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords