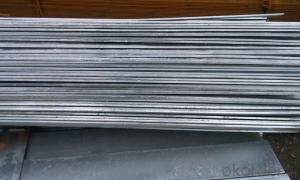

75x10 Flat Bar 50x10 Flat Bar 22mm/ Hot Rolled Flat Steel/ Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 23000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Are steel flat bars suitable for making cutting or scraping tools?

- Steel flat bars can indeed be suitable for making cutting or scraping tools, depending on the specific requirements and intended use. Steel is a strong and durable material, making it ideal for tools that require sharpness and longevity. Flat bars can be easily shaped and formed into various cutting or scraping tool designs, offering versatility and customization options. However, the choice of steel grade is crucial to ensure the desired performance. High carbon steel, for example, is known for its hardness and ability to hold a sharp edge, making it suitable for cutting tools like knives or chisels. On the other hand, stainless steel may be preferred for tools that require resistance to corrosion, such as scrapers used in wet or humid environments. Ultimately, the suitability of steel flat bars for making cutting or scraping tools depends on factors like the intended application, required hardness, and desired resistance to wear or corrosion.

- Q: Are steel flat bars suitable for machining operations?

- Yes, steel flat bars are suitable for machining operations. Steel flat bars are commonly used in various machining applications due to their versatility and durability. They can be easily machined using different processes such as cutting, drilling, milling, and turning. The flat surface of the bar provides a stable and consistent material for machining, allowing for precise and accurate operations. Additionally, steel flat bars offer excellent strength and toughness, making them ideal for heavy-duty machining tasks. Overall, steel flat bars are a reliable choice for machining operations in industries such as manufacturing, construction, and automotive.

- Q: What are the standards for the use of galvanized steel angles and flat steel for grounding?

- The top of the grounding body from the ground 0.5 ~ 0.8m, in order to avoid thawing soil, soil resistivity or steel angle as the root number of the ground around the body and decide, generally not less than two, each spacing is 3 ~ 5m

- Q: What line is the LEB line, please? Is it wire or flat steel or galvanized round bar?

- General requirements of the building's outdoor metal doors and windows, equipment shell, distribution box, etc., are required to do a second potential connection,It has not seen the specific technical requirements, we can use the past construction experience, building floor steel ring, Liang Gangjin, reinforced connecting line, equipment shell available 6 mm galvanized welded steel garden.

- Q: What are the different types of surface defects in brass steel flat bars?

- There are various types of surface defects that can be found on brass steel flat bars, which can occur during the manufacturing, processing, or handling of the material. Some common surface defects in brass steel flat bars include the following: 1. Scratches: Shallow marks or abrasions on the surface of the flat bar that can be caused by mishandling, contact with sharp objects, or improper storage. These scratches can affect the bar's appearance and potentially weaken its structural integrity. 2. Pitting: Small, localized cavities or depressions on the surface of the flat bar. Pitting can occur due to exposure to corrosive environments or chemical reactions. It can compromise the smoothness of the surface and may lead to further corrosion if not treated. 3. Rust or corrosion: When exposed to moisture, humidity, or aggressive chemicals, brass steel flat bars can develop rust or corrosion. Rust appears as a reddish-brown coating on the surface and can weaken the bar over time. Corrosion can also result in pitting or flaking of the surface. 4. Dents or dings: Small deformations or indentations on the surface of the flat bar. These defects can occur during handling or transportation, especially if the bars are not adequately protected. While dents may not significantly impact the structural integrity, they can affect the overall appearance. 5. Roll marks: Surface imperfections that occur during the rolling process used to shape the brass steel flat bars. These marks can appear as ridges, depressions, or patterns on the surface. Although they may not affect the functionality of the bar, they can impact its aesthetic appeal. 6. Scale: The layer of oxides that forms on the surface of brass steel flat bars during heating or high-temperature processes. Scale appears as a thin, flaky coating that can be easily removed mechanically. While scale does not affect the structural integrity, it can impact the surface finish. It is important to understand that the severity of surface defects can vary, and the acceptability of certain defects depends on the specific application or industry standards. Regular inspection, proper handling, and appropriate surface treatment methods can help mitigate and prevent these surface defects in brass steel flat bars.

- Q: Can steel flat bars be used for making brackets or supports for plumbing systems?

- Yes, steel flat bars can be used for making brackets or supports for plumbing systems. Steel is a commonly used material in construction and plumbing due to its strength and durability. Steel flat bars provide a sturdy and reliable option for creating brackets or supports that can effectively hold the weight of plumbing pipes and fixtures. Additionally, steel is resistant to corrosion, making it suitable for use in wet environments such as plumbing systems. Overall, steel flat bars are a suitable choice for making brackets or supports for plumbing systems.

- Q: What are the different types of surface patterns available for steel flat bars?

- There are several different types of surface patterns available for steel flat bars, each offering unique characteristics and benefits. Some of the common surface patterns include: 1. Smooth surface: This is the most basic and common surface pattern for steel flat bars. It has a plain, flat surface without any visible patterns or textures. A smooth surface is typically preferred when appearance is not a priority and the focus is on functionality. 2. Serrated surface: Serrated surface patterns feature small grooves or ridges along the length of the steel flat bar. This pattern provides enhanced grip and traction, making it suitable for applications where slip resistance is crucial, such as walkways, ramps, or stair treads. 3. Checker plate pattern: Also known as diamond plate or tread plate pattern, it features a raised diamond-shaped pattern on the surface. This pattern offers excellent slip resistance and is commonly used in industrial settings, loading docks, truck beds, or flooring applications. 4. Hammered pattern: Hammered surface patterns have a textured appearance that resembles the marks left by a hammer. This pattern adds an aesthetic appeal to the steel flat bar and is often used in decorative applications, such as architectural detailing or furniture. 5. Galvanized surface: Galvanization is a process where steel is coated with a layer of zinc to protect it from corrosion. Galvanized steel flat bars have a shiny and smooth surface, providing excellent corrosion resistance and durability. This surface pattern is commonly used in outdoor applications or areas prone to moisture exposure. 6. Painted or powder-coated surface: Steel flat bars can also be painted or powder-coated to provide a specific color or finish. This surface pattern allows for customization and can be used to match the surrounding environment or for aesthetic purposes. It is important to consider the intended use and requirements of the steel flat bar when choosing the appropriate surface pattern. Each pattern offers distinct advantages and selecting the right surface pattern can ensure optimal performance and longevity of the steel flat bar in its intended application.

- Q: Can steel flat bars be used for manufacturing kitchen equipment or appliances?

- Yes, steel flat bars can be used for manufacturing kitchen equipment or appliances. Steel is a versatile and durable material that is commonly used in the manufacturing industry. It offers excellent strength and resistance to corrosion, making it suitable for use in kitchen equipment that is exposed to moisture and high temperatures. Steel flat bars can be shaped, welded, and formed into various components and structures, making them ideal for constructing kitchen appliances such as cabinets, countertops, shelving, and even utensils. Additionally, steel is easy to clean and maintain, making it a practical choice for kitchen equipment where hygiene is essential. Overall, steel flat bars are a reliable and popular choice for manufacturing kitchen equipment and appliances due to their strength, durability, and versatility.

- Q: What are the common methods of protecting steel flat bars from corrosion?

- The common methods of protecting steel flat bars from corrosion include applying protective coatings such as paint or powder coating, using galvanization to create a protective zinc layer, employing corrosion inhibitors, and implementing proper maintenance practices such as regular cleaning and inspections.

- Q: Can steel flat bars be used for manufacturing furniture?

- Yes, steel flat bars can be used for manufacturing furniture. They are commonly used as structural components for creating sturdy and durable furniture pieces. Steel flat bars offer strength, stability, and versatility, making them suitable for various furniture designs and styles.

Send your message to us

75x10 Flat Bar 50x10 Flat Bar 22mm/ Hot Rolled Flat Steel/ Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 23000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords