Hot Rolled Steel Flat Bar with Enough Thickness 10mm Chinese Standard

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Hot Rolled Steel Flat Bar with Enough Thickness 10mm Chinese Standard Description:

Hot rolled steel flat bar with enough thickness 10mm Chinese standard is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Hot rolled steel flat bar with enough thickness 10mm Chinese standard is usually made of structural steel and is used in construction and civil engineering. The hot rolled steel flat bar with enough thickness 10mm Chinese standard resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Hot rolled steel flat bar with enough thickness 10mm Chinese standard theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Hot Rolled Steel Flat Bar with Enough Thickness 10mm Chinese Standard:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

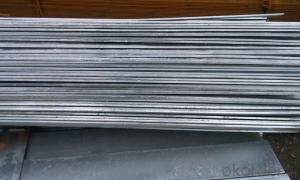

3. Hot Rolled Steel Flat Bar with Enough Thickness 10mm Chinese Standard Images:

4. Hot Rolled Steel Flat Bar with Enough Thickness 10mm Chinese Standard Specification:

Alloy No | Grade | Element(%) | ||||

C

| Mn

| S

| P

| Si

| ||

Q235

|

B

|

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

Alloy No | Grade | Yielding strength point(Mpa) | Tensile strength (Mpa) | Elongation after fracture(%) | ||||||

Thickness (mm) | Thickness (mm) | |||||||||

≤16 | >16--40 | >40--60 | >60--100 | ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | ≥ | |||||||||

Q235 |

B |

235 |

225 |

215 |

205 |

375--500 |

26 |

25 |

24 |

23 |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: Can steel flat bars be used for manufacturing railway components or tracks?

- Yes, steel flat bars can be used for manufacturing railway components or tracks. Steel is a commonly used material in the railway industry due to its strength, durability, and ability to withstand heavy loads. Flat bars made from steel are often used for various railway components such as brackets, clamps, fasteners, and supports. They can also be used for manufacturing sections of railway tracks, particularly for smaller tracks or temporary installations. However, for mainline railway tracks, the use of steel flat bars alone may not be sufficient, and other specialized components such as rails and sleepers are typically required for a safe and reliable track system.

- Q: How do steel flat bars perform in terms of water resistance?

- Steel flat bars are generally not very water resistant. Steel is prone to rusting when exposed to moisture or water. If the steel flat bars are not properly treated or protected, they can easily corrode and degrade when in contact with water. However, if the steel flat bars are coated with a protective layer such as paint or galvanized coating, their water resistance can be significantly improved. These coatings act as a barrier, preventing water from directly coming into contact with the steel surface and reducing the risk of rusting. Additionally, regular maintenance and proper storage of steel flat bars can help prolong their lifespan and enhance their water resistance.

- Q: Can steel flat bars be heat treated?

- Yes, steel flat bars can be heat treated. Heat treatment is a process used to alter the physical and mechanical properties of steel by subjecting it to specific heating and cooling cycles. This process is commonly used to increase the hardness, strength, and toughness of the steel flat bars. Heat treatment can be performed through various methods such as annealing, normalizing, quenching, and tempering, depending on the desired outcome. Each method involves heating the steel to a specific temperature and then cooling it at a controlled rate. Heat treatment is commonly employed in industries such as manufacturing, construction, and automotive to enhance the performance and durability of steel flat bars.

- Q: Are steel flat bars suitable for indoor or outdoor applications?

- Steel flat bars can be used both indoors and outdoors due to their versatility. Whether it's a construction project in any environment, steel is a popular choice. The durability and corrosion resistance of steel flat bars make them perfect for outdoor use, even in harsh weather conditions and with exposure to moisture. They can be utilized for various outdoor structures including fences, gates, and handrails. Additionally, indoor projects like furniture, shelving, and support beams can benefit from the use of steel flat bars. Furthermore, these bars can easily be painted or coated to prevent rust and enhance their appearance. In conclusion, steel flat bars are a dependable and adaptable option for both indoor and outdoor applications.

- Q: What is the maximum width-to-thickness ratio for steel flat bars?

- Industry standards and specifications typically determine the maximum width-to-thickness ratio for steel flat bars. These standards vary depending on the specific application and requirements of the flat bar. However, a widely accepted guideline suggests that the width should not exceed 12 times the thickness. Going beyond this ratio can result in heightened susceptibility to bending, twisting, or buckling when subjected to certain loads or stresses. To obtain more precise information about the maximum width-to-thickness ratio for a specific steel flat bar application, it is essential to refer to the appropriate standards and specifications or seek advice from a structural engineer or steel manufacturer.

- Q: Can steel flat bars be used in automotive manufacturing?

- Yes, steel flat bars can be used in automotive manufacturing. Steel flat bars are commonly used in various applications within the automotive industry due to their strength, durability, and versatility. They can be used in the fabrication of various automotive components, such as brackets, supports, frames, hinges, and reinforcements. Steel flat bars offer excellent structural integrity and can withstand heavy loads, making them suitable for use in automotive manufacturing. Additionally, steel is a cost-effective material and readily available, making it a popular choice in the automotive industry.

- Q: Can steel flat bars be used for making conveyor belts?

- No, steel flat bars are not suitable for making conveyor belts. Conveyor belts require flexible and durable materials that can bend and conform to the shape of the pulleys and rollers while maintaining strength and durability. Steel flat bars are rigid and inflexible, making them unsuitable for this purpose.

- Q: How do steel flat bars compare to fiberglass flat bars?

- Steel flat bars are known for their strength and durability, making them suitable for heavy-duty applications. They offer excellent load-bearing capabilities and are resistant to bending or warping under pressure. On the other hand, fiberglass flat bars have the advantage of being lightweight and corrosion-resistant. They are often used in applications where weight is a concern or where exposure to chemicals or moisture is a factor. Ultimately, the choice between steel and fiberglass flat bars depends on the specific requirements of the project and the desired properties of the material.

- Q: The technological process of flat steel

- The working principle of precision steel production process of flat steel finishing machine is cold flat bad hair with two sets of upper and lower staggered leveling wheel thickness pre leveling and final leveling; with a pair of oppositely disposed finishing wheel in the width direction of extrusion, the width is compressed and reaches the expected parameters and the amount of compression can be adjusted; with 5 aspects of straightening straightening wheel arrangement of the staggered width. This system is mainly composed of a control box, finishing roller, pre leveling unit, finishing unit, straightening unit.

- Q: Do lightning protection, lead out of the galvanized round steel, flat steel needs to be inspected?

- When you buy hot galvanized round steel and flat steel, please provide inspection documents. In addition, in the procurement of materials must be explained that hot galvanizing, or else the business to provide you with cold plating will not work; there is a certain price gap between the two.

Send your message to us

Hot Rolled Steel Flat Bar with Enough Thickness 10mm Chinese Standard

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords