5xxx Series Aluminum Coil - Aluminum Tread Plate with Five Bars Embossed Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Description of Auminium Tread Plate with Five Bars Embossed Sheet

Alloy: 1050, 1060, 1100, 3003, 3005, 3105, 5052, etc

Thickness: 0.2mm~20mm

Temper: H14, 18, 24, 26, 32

Width: 10mm- 1500mm

2. Application of Auminium Tread Plate with Five Bars Embossed Sheet

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Auminium Tread Plate with Five Bars Embossed Sheet

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

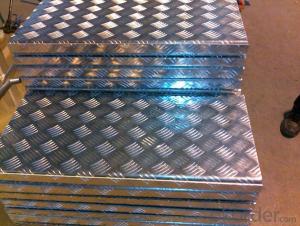

5. Image of Auminium Tread Plate with Five Bars Embossed Sheet

6. Package and shipping of Auminium Tread Plate with Five Bars Embossed Sheet

eye to sky

eye to wall

with wooden pallet (wooden case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How do aluminum coils contribute to energy-efficient appliances?

- Aluminum coils contribute to energy-efficient appliances by enhancing the heat transfer process. Due to their high thermal conductivity, aluminum coils facilitate the rapid transfer of heat, allowing appliances such as air conditioners, refrigerators, and heat pumps to operate more efficiently. This improved heat transfer ensures that the appliances require less energy to achieve the desired cooling or heating effect, ultimately reducing overall energy consumption and promoting energy efficiency.

- Q: What is the typical hardness of aluminum coils?

- The typical hardness of aluminum coils can vary depending on the specific alloy and temper used, but generally falls within the range of 40-70 on the Rockwell B scale.

- Q: I am so confused right know. I want to cook something using an aluminium foil. Is the reflective side supposed to be inside or outside?

- not usually too big a deal either way really, but make absolutely sure you NEVER use it in a microwave as bill suggested!!!

- Q: What specific conditions or considerations need to be taken into account when utilizing aluminum coils in high-temperature settings?

- <p>When using aluminum coils in high-temperature environments, it's crucial to consider the material's melting point, which is around 660掳C (1220掳F). Ensure that the operating temperature does not exceed this threshold to avoid deformation or failure. Additionally, aluminum's strength and conductivity can be affected by high temperatures, so it's important to account for potential changes in performance. Protective coatings or treatments may be necessary to prevent oxidation and maintain the coil's integrity. Always consult material specifications and consult with material science experts to determine the suitability of aluminum coils for specific high-temperature applications.</p>

- Q: Are aluminum coils suitable for coil coating applications?

- Yes, aluminum coils are suitable for coil coating applications. Aluminum is widely used in coil coating due to its excellent corrosion resistance, lightweight nature, and high strength-to-weight ratio. It is also highly malleable, allowing for easy shaping and forming during the coil coating process. Additionally, aluminum coils can be coated with various types of paints and coatings, providing a wide range of color and finish options. Overall, aluminum coils are a popular choice for coil coating applications due to their versatility, durability, and aesthetic appeal.

- Q: how tall is a crushed aluminium soda can compared to a non crushed one.i need measurements in centimeters please.ALSO!! AN IMAGE that actually has both of the two with the measurements would be SUPER HELPFUL

- I recognize that there are places in this world where aluminum beverage cans are very exotic, very rare, and may even be quite expensive. I can also understand that, in such a special place, one may have never actually held one of these objects in your own hands. If you live in such a place, then I can understand why you need to seek assistance on Yahoo Answers. I am, personally, quite surprised that you would have internet access in such a place. For your answer... it depends on how you crush the can but it is quite possible to crush your standard aluminum beverage can to a thickness of fractions of a centimeter.

- Q: Can aluminum coils be welded or soldered?

- Yes, aluminum coils can be welded or soldered. Welding and soldering are two common methods used to join aluminum coils together. Welding involves melting the aluminum material in the coils and fusing them together using heat and pressure. This process requires specialized equipment and skilled operators. On the other hand, soldering is a process that uses a lower melting point filler material, called solder, to join the aluminum coils. Soldering is typically used for lighter applications and requires less heat than welding. Both welding and soldering can effectively join aluminum coils, but the choice between the two methods depends on the specific requirements of the project, the equipment available, and the expertise of the operator.

- Q: I was going to buy a turkey roaster pan today and an elderly couple stopped me and told me to buy another one that was made of stainless steel instead of aluminum because aluminum does something to your brain. What is the story?Just curious. Does this also ring true for using a sheet of aluminum foil over baking sheets while cooking cookies or fries or something? I always coat my cookie sheets with foil. Just curious...

- Don't know what it does to your brain, but it does dissolve and leach into the food, especially when salt comes into contact with it. Buy an enameled roasting pan, it will last your lifetime, and you can clean it with oven spray. When making cookies or cake, use parchment or even wax paper. It works really good, and parchment is non-stick. Wax paper is great for lining cake pans with, cut out the rings and line the insides with strips. After you remove the cake, peel off the wax paper and all the crumbs go with it. Makes them real nice to frost. I use wax paper in the microwave instead of paper towels or plastic wrap. It's very versitile and cheap!

- Q: Can aluminum coils be used in the production of aluminum composite panels?

- Yes, aluminum coils can be used in the production of aluminum composite panels. Aluminum coils are often used as the base material for manufacturing aluminum composite panels (ACP). ACPs are made by bonding a thin aluminum coil to a thermoplastic core using a bonding adhesive. The aluminum coil provides strength and stability to the panel while the thermoplastic core offers insulation and rigidity. The use of aluminum coils allows for flexibility in design and customization of the panels. Additionally, aluminum coils are durable, lightweight, and resistant to corrosion, making them an ideal choice for ACP production.

- Q: This question asks for a comparison of the costs involved in purchasing new aluminum coils versus recycling old ones.

- <p>The cost of buying new aluminum coil versus recycling old ones can vary significantly based on several factors including market prices, quality of the recycled material, and the cost of recycling processes. Generally, recycling aluminum is more cost-effective as it requires less energy and resources compared to producing new aluminum from raw materials. The cost of recycled aluminum can be as low as half of that for new aluminum. However, the exact cost will depend on current market conditions and the specific requirements of the aluminum coils in question. It's advisable to get quotes from suppliers and recycling companies to determine the most economical option for your specific needs.</p>

Send your message to us

5xxx Series Aluminum Coil - Aluminum Tread Plate with Five Bars Embossed Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords