5052 Mill Finish Mirror Aluminum Coil for Channel Letter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Mirror Aluminium Coil for Channel Letter

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of Mill Finish Mirror Aluminium Coil for Channel Letter

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of PVDF Painted Aluminum Coil Competitive Price and BEST Manufacture and factor

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

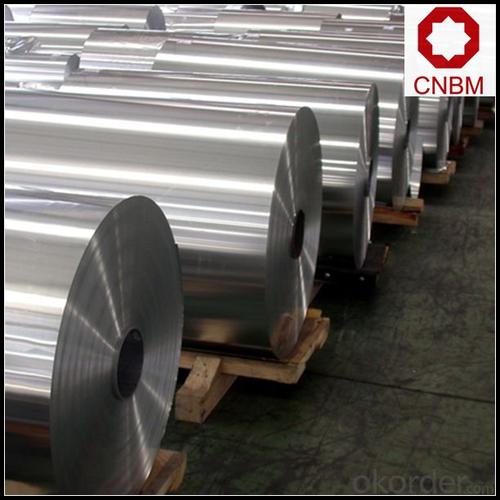

5. Image of Mill Finish Mirror Aluminium Coil for Channel Letter

6. Package and shipping of Mill Finish Mirror Aluminium Coil for Channel Letter

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: I am sanding tool marks out of aluminum rims and plan on polishing them. Any help to make sanding them easier would be welcome.

- Eastwood okorder /

- Q: Can aluminum coils be used in building facades?

- Building facades can indeed incorporate aluminum coils. Due to its numerous advantages, aluminum is a favored material for such applications. Its lightweight nature, durability, and resistance to corrosion make it ideal for exterior use. Furthermore, aluminum coils can be shaped into various forms and sizes, enabling limitless design possibilities. Additionally, aluminum offers a wide selection of finishes, such as anodized, painted, and coated, enhancing customization options for building facades. Moreover, aluminum is an environmentally sustainable material as it can be 100% recycled, making it an eco-friendly choice for construction projects. In conclusion, aluminum coils offer both aesthetic appeal and functional performance, making them a feasible choice for building facades.

- Q: What is the role of aluminum coils in the construction of ships?

- Aluminum coils are used in the construction of ships primarily for their lightweight and corrosion-resistant properties. They are commonly used in the fabrication of ship hulls, decks, and superstructures. The use of aluminum coils reduces the overall weight of the ship, improving fuel efficiency and increasing payload capacity. Additionally, the corrosion resistance of aluminum helps to prolong the lifespan of the ship, reducing maintenance costs in the long run.

- Q: which metal is very common today and which one will be most common in future. steel or aluminum

- aluminum costs more to produce, but has some very good proprieties, you will likely see steel and aluminum way into the future in about the same ratios as today

- Q: What are the compositions of aluminum coil coating?

- The common compositions are crylic resin, solid inorganic filler, different pigments, flatting agent and so on.

- Q: Can aluminum coils be used for electrical conductivity purposes?

- Using aluminum coils for electrical conductivity purposes is not possible. Although aluminum is a decent conductor of electricity, it is not appropriate for coils that are specifically intended for electrical conductivity. Aluminum has a higher resistance in comparison to materials like copper or silver, which are frequently used for electrical conductivity purposes. Furthermore, aluminum has a lower melting point than copper, therefore utilizing it in coils for high electrical currents can result in overheating problems. Consequently, it is more typical to use materials such as copper or silver for electrical conductivity purposes, particularly in situations where high conductivity and low resistance are necessary.

- Q: Can aluminum coils be bent or shaped?

- Yes, aluminum coils can be bent or shaped. Aluminum is a highly malleable and ductile metal, meaning it can be easily manipulated and formed into various shapes without breaking or cracking. The flexibility of aluminum allows it to be bent, rolled, or shaped into coils, making it a popular choice for various applications such as in the manufacturing of air conditioning systems, automotive parts, and packaging materials. The ability to bend and shape aluminum coils makes them versatile and adaptable to specific design requirements, allowing for efficient and precise customization in various industries.

- Q: What are the density and specific gravity values of aluminum coils?

- The density of aluminum coils is approximately 2.7 grams per cubic centimeter (g/cm³) or 2700 kilograms per cubic meter (kg/m³). The specific gravity of aluminum coils is approximately 2.7.

- Q: Are aluminum coils compatible with different joining methods?

- Yes, aluminum coils are compatible with different joining methods. Some common joining methods for aluminum coils include welding, soldering, brazing, and mechanical fastening. The choice of joining method depends on the specific application and requirements.

- Q: Are aluminum coils suitable for architectural applications?

- Yes, aluminum coils are suitable for architectural applications. Aluminum is a highly versatile and durable material that is commonly used in the construction industry for various architectural applications. Aluminum coils offer several advantages for architectural use, including their lightweight nature, corrosion resistance, and ability to be easily formed into desired shapes and sizes. These coils can be used in architectural applications such as roofing, cladding, facades, and gutters, among others. Additionally, aluminum coils can be coated with different finishes, providing a wide range of aesthetic options for architects and designers. Overall, aluminum coils are an excellent choice for architectural applications due to their strength, durability, and flexibility.

Send your message to us

5052 Mill Finish Mirror Aluminum Coil for Channel Letter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords