5005 Aluminum Coil - Color Coating PE Painting for Inside Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coating Aluminium Coil PE Painting for Inside Doors

Material | Alloy Aluminum 1XXX,3XXX,5XXX or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating,PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Color Coating Aluminium Coil PE Painting for Inside Doors

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coating Aluminium Coil PE Painting for Inside Doors

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

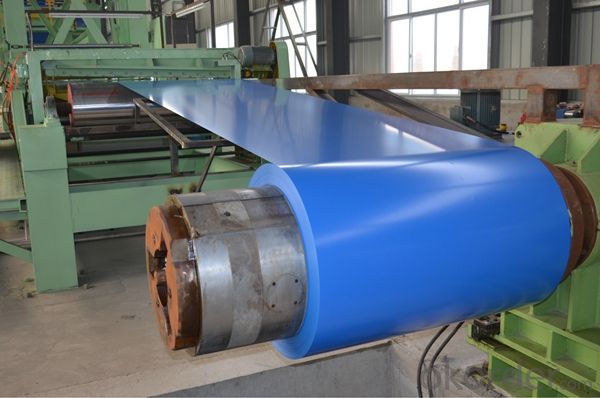

5. Image of Color Coating Aluminium Coil PE Painting for Inside Doors

6. Package and shipping of Color Coating Aluminium Coil PE Painting for Inside Doors

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the potential applications of laminated aluminum coils?

- Laminated aluminum coils have a wide range of potential applications. They can be used in industries such as electrical, automotive, aerospace, and construction. Some specific applications include electrical transformers, heat exchangers, automotive radiators, air conditioning systems, and architectural facades. The lamination process enhances the durability, heat and corrosion resistance, and electrical conductivity of the coils, making them suitable for various demanding environments and applications.

- Q: What is the corrosion resistance of aluminum coils in saltwater environments?

- Aluminum coils have excellent corrosion resistance in saltwater environments. This is due to the formation of a protective oxide layer on the surface of the aluminum, which acts as a barrier against corrosion. This oxide layer prevents the saltwater from coming into direct contact with the aluminum, effectively reducing the risk of corrosion. Additionally, aluminum is inherently resistant to saltwater corrosion because it is a relatively inert metal. As a result, aluminum coils are commonly used in various marine applications, such as boat hulls, offshore structures, and saltwater cooling systems. However, it is important to note that prolonged exposure to saltwater can still result in some level of corrosion over time. Regular maintenance and appropriate protective coatings can help enhance the longevity and performance of aluminum coils in saltwater environments.

- Q: What are the different types of aluminum alloys used for making coils?

- There are various types of aluminum alloys used for making coils, including 1100, 3003, 5052, and 6061. These alloys differ in terms of their composition and properties, such as strength, corrosion resistance, and formability, allowing manufacturers to select the most suitable alloy based on the specific requirements of the application.

- Q: Can aluminum coils be used in the production of electronic devices?

- Yes, aluminum coils can be used in the production of electronic devices. Aluminum is a commonly used material in the electronics industry due to its excellent conductivity, lightweight nature, and resistance to corrosion. Aluminum coils are often utilized in various electronic components like transformers, inductors, and coils for power supply applications.

- Q: And what are the advantages/disadvantages of steel aluminum in building cars?Which would be better for building cars?

- Similarities - They are both metals, conduct electricity and heat and deform elastically then plastically. Difference - every mechanical property there is! Density, elastic modulus (stiffness), strength and hardness are all higher for steel. But, for building cars it is about design, weight, forming, manufacturing, joining and cost. Better depends on what you are trying to acheive - cost or weight saving - and there is not a hard and fast rule as to which metal helps which. Have a look at either the Jaguar S type which is aluminium (as is the Audi A6). Most Ford cars are still steel (as are Renault). Check out the crash test results.

- Q: How are aluminum coils used in the production of gutters and downspouts?

- The production of gutters and downspouts relies heavily on aluminum coils. These coils serve as the main material for manufacturing seamless gutters, which are renowned for their durability, longevity, and aesthetic appeal. To initiate the production process, specialized gutter machines are utilized to feed the aluminum coils. These machines shape the coils into the desired gutter profile, usually in the form of a lengthy continuous piece. Subsequently, the coil is cut into appropriate lengths that correspond to the measurements required for a specific building or project's gutter system. Once cut, the aluminum coil undergoes various bending and folding techniques to shape and form it. This transformation allows the coil to assume the seamless gutter shape necessary for efficiently collecting and channeling rainwater away from a building's roof and foundation. The seamless design eliminates the risk of leaks and enhances the overall functionality of the gutter system. Moreover, the aluminum coils used in gutter production offer several advantages. Firstly, aluminum is lightweight yet sturdy, making it an ideal material for gutters and downspouts. It possesses resistance to rust and corrosion, ensuring the longevity of the gutter system even in harsh weather conditions. Additionally, aluminum is highly malleable, enabling customization of shapes and sizes to meet the specific requirements of different buildings. In conclusion, aluminum coils play an integral role in the production of aesthetically pleasing, durable, and highly functional gutters and downspouts. Their use as the primary material guarantees long-lasting performance, resistance to corrosion, and customization options to cater to various architectural needs.

- Q: Is it possible to create a baking pan using aluminum coil material?

- <p>Yes, you can use aluminum coil to make a baking pan. Aluminum is a popular material for baking pans due to its excellent heat conductivity, which allows for even heating. When creating a baking pan from aluminum coil, ensure that the coil is food-grade and that the edges are properly sealed to prevent any sharp edges. It's also important to consider the thickness of the aluminum, as a thicker gauge will distribute heat more evenly. Always follow safety guidelines and ensure that the aluminum coil is suitable for use in an oven.</p>

- Q: What are the weight savings achieved by using aluminum coils?

- Compared to materials like steel, significant weight savings can be achieved by using aluminum coils. Aluminum, a lightweight metal with a density approximately one-third that of steel, allows for greatly reduced overall weight when utilizing aluminum coils instead of steel coils. The benefits of weight savings attained through aluminum coil usage are numerous. In industries such as automotive and aerospace, reducing weight is crucial for enhancing fuel efficiency and increasing payload capacity. Lighter vehicles and aircraft require less energy for operation and can accommodate more passengers or cargo, resulting in cost savings, improved performance, and minimized environmental impact. Moreover, the weight savings obtained from aluminum coils can provide practical advantages in other applications as well. For instance, in HVAC systems, lighter coils facilitate easier installation and transportation, thereby reducing labor and logistics costs. The actual weight savings achieved by utilizing aluminum coils will vary depending on the specific application and design specifications. Nonetheless, it is widely acknowledged that aluminum coils offer a significant weight advantage over alternative materials. The actual weight savings can range from 30% to 70% or more, depending on the specific comparison being made. To summarize, the weight savings achieved through the use of aluminum coils can be substantial. This lightweight material offers numerous benefits in terms of fuel efficiency, payload capacity, performance, and cost savings. When prioritizing weight reduction, aluminum coils are an excellent choice for a wide range of industries and applications.

- Q: How do aluminum coils impact energy efficiency?

- Aluminum coils have a significant impact on energy efficiency due to their excellent heat transfer properties. They are commonly used in air conditioning systems and heat pumps as they enhance the heat exchange process, allowing for faster and more efficient cooling or heating. The high thermal conductivity of aluminum ensures that the system operates effectively, reducing energy consumption and increasing overall efficiency.

- Q: What are cold rolling aluminum coil and hot rolling aluminum coil? What are their features?

- If the rolling temperature is above the crystallization one, it is hot rolling, otherwise it is cold rolling.

Send your message to us

5005 Aluminum Coil - Color Coating PE Painting for Inside Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords