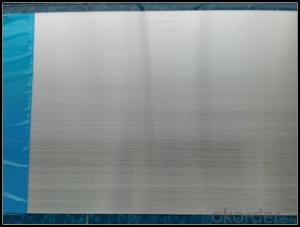

4x8 Brushed Aluminum Sheets for Curtain Wall 1050 1060 H12 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. specification aluminium alloy sheets/plates

Material | 1,2,3,5,6,7,8 series |

Temper | O, F, H14, H34, H32, H112, T4, T6 |

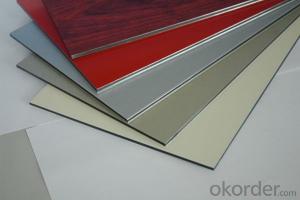

Surface treatment | Mill Finish,Anodized,Eletropharesis,Powder Coated, Wooden Finish, Polish |

Colour | Silver,Black,Red,Blue,or as required |

Length | As required |

Shape | Plainen,bossed,or as per the drawings and samples |

Fabrication | cutting,drilling,punching,bending,etc |

Tolerances | As per your requirements |

Package | inner plastic paper interleaving each piece profile,outer fixed by plywood, or as per your requirements |

Payment terms | TT |

Price terms | FOB;CIF;CNF |

Delivery time | 15-20 days after order confirmation |

Certification | ISO 9001:2008; |

Application | Decorations,Fence,Building,Aviation industry,Mechancal equipment |

Capacity | 5000 tons per month |

Min order quantity | 5 Metric ton |

Chemical Composition | %SiFeCuMnMgCrNiZnTiZrMin0.000.003.800.301.200.00 0.000.00 Max0.100.124.400.901.800.10 0.250.15

|

2. Properties:

1.High hardness, hard aluminum series.

2.Fair corrosion resistance. Heat treatable

3.Good workability. Good appearance

4.High quality and reasonable price.

5.Our product is your best choice.

3.Size

Thickness: 0.15-3.0mm(Tolerance:+/-0.02mm)

Width:150-2000MM(Tolerance:+/-1mm)

Length:600-6000MM(Tolerance:+/-1mm)

4.Products category

Thick plate | PS plate |

Oversized plate | Backing plate |

Soft alloy sheet | Contour plate |

Hard alloy sheet | Bottle caps sheets |

Equipment cabinet plate | Can lid plate |

Thread plate | Plain aluminum sheet |

Curtain wall plate | Quenched plate |

High grade plate | Pre-stretching plate |

5. Capacity of aluminum sheets/plates

Our main products are aluminum alloy materials, including aluminum alloy seamless

pipes, aluminum alloy welded pipes, aluminum alloy cold drawn pipes, aluminum alloy

extruded pipes, aluminum alloy extruded bars, aluminum alloy plates and sheets, and

aluminum alloy coils, aluminum alloy forging, etc .

Aluminum alloy Typical Mechanical Properties

Grades and status | Tensile strength (25°C MPa) | Yield Strength (25°C MPa | Hardness force 500kg 10mm | Elongation thickness 1.6mm(1/16in) |

5052-H112 | 175 | 195 | 60 | 12 |

5083-H112 | 180 | 211 | 65 | 14 |

6061-T651 | 310 | 276 | 95 | 12 |

7050-T7451 | 510 | 455 | 135 | 10 |

7075-T651 | 572 | 503 | 150 | 11 |

2024-T351 | 470 | 325 | 120 | 20 |

6. Application

Building material, insulation, shoes and tens eyes, corner beads, automotive industrial,

POP can bottle and cap, deep-proceeding case, light industry,

TV back board, PP caps, cell mask and so on.

7.Photos

- Q: could aluminum sheet be attracted by magnet?

- no, it couldn't.

- Q: What is the density of the 2A12 aluminum plate?

- 2.75 density. Shenzhen dexincheng metal plate is sold. Specifications are all complete.

- Q: Can aluminum sheets be an alternative to wood in certain applications?

- Yes, aluminum sheets can be an alternative to wood in certain applications. Aluminum sheets have several advantages over wood, including being lightweight, durable, and resistant to corrosion and fire. They can be used in various industries such as construction, automotive, aerospace, and marine, where wood may not be suitable due to its limitations. However, the selection of material depends on the specific requirements of the application and the desired properties needed.

- Q: This question asks for the method to determine the quantity of aluminum sheet required for a specific project.

- <p>To calculate the amount of aluminum sheet needed for a project, first determine the dimensions of the area to be covered. Measure the length and width to find the total area in square units. If the project involves complex shapes, break it down into simpler shapes like rectangles and circles, and calculate the area for each. Multiply the total area by the thickness of the aluminum sheet required. Finally, consider any additional material for overlaps or wastage, typically around 5-10%. The total volume calculated will give you the amount of aluminum sheet needed for the project.</p>

- Q: Can aluminum sheets be used as a substitute for steel in certain applications?

- Certain applications can utilize aluminum sheets as a replacement for steel. Aluminum, a versatile and lightweight material, offers numerous advantages over steel. Its high strength-to-weight ratio allows it to deliver comparable strength while being considerably lighter. This quality makes aluminum sheets an outstanding option for weight-sensitive applications, like those in the aerospace, automotive, and transportation industries. Furthermore, aluminum boasts exceptional corrosion resistance, negating the necessity for supplementary protective coatings or treatments. Consequently, aluminum sheets are suitable for employment in marine environments or other corrosive settings. Additionally, aluminum sheets possess remarkable thermal conductivity, making them ideal for applications that necessitate heat dissipation, such as heat exchangers or radiators. Moreover, aluminum is more pliable than steel, facilitating easier shaping and forming. This attribute renders aluminum sheets suitable for applications that require intricate or complex designs. However, it is vital to acknowledge that aluminum has lower tensile strength in comparison to steel. Consequently, in applications demanding substantial load-bearing capacities or structural integrity, steel may remain the preferred choice. In such instances, a thorough evaluation of specific requirements and trade-offs between weight, strength, and cost should be conducted before opting to use aluminum sheets as a steel substitute.

- Q: This question asks for criteria or factors to consider when selecting a high-quality aluminum sheet.

- <p>To choose a quality aluminum sheet, consider the following factors: 1) Thickness and weight, which should meet your specific project requirements. 2) Surface finish, ensuring it's smooth and free from defects. 3) Purity and alloy type, as different alloys have different properties. 4) Certifications, ensuring the sheet meets industry standards. 5) Supplier reputation and customer reviews for reliability. 6) Price, ensuring it's reasonable for the quality. 7) Conductivity and strength, depending on your application. 8) Corrosion resistance, important for longevity. Always inspect the sheet for any visible defects and ensure it's from a reputable supplier.</p>

- Q: Can aluminum sheets be used for roofing applications?

- Yes, aluminum sheets can be used for roofing applications. Aluminum is a lightweight and durable material that offers excellent resistance to corrosion. It is particularly suitable for areas with high humidity or coastal regions where saltwater exposure is common. Aluminum roofing sheets are known for their longevity and low maintenance requirements. They are also fire-resistant and can withstand extreme weather conditions, making them a popular choice for both residential and commercial roofing projects. Additionally, aluminum sheets are easy to install and can be shaped and formed to fit various roof designs. Furthermore, aluminum is a sustainable material as it can be recycled repeatedly without losing its quality, making it an environmentally friendly option for roofing applications.

- Q: Can aluminum sheets be used in aerospace industries?

- Yes, aluminum sheets can be used in aerospace industries. Aluminum is commonly used in the aerospace industry due to its lightweight, high strength-to-weight ratio, and corrosion resistance properties. It is used for various applications such as aircraft structures, wings, fuselages, and skins.

- Q: My new home has a mix of copper and aluminum wiring. My mother used a shop vac in one of the recepticles last week and blew two of them in my bedroom. Then this weekend my brother was replacing my exhaust fan in the bathroom and that proceeded to blow the entire bedroom and bathroom including ceiling fans, lights and all recepticles. Does anyone have any ideas?

- You said new home. Aluminum hasn't been used in house wiring for many years. It is now only used for the main service wires coming in to the panel. Shop vacs can trip 15 amp bedroom circuits. I think you need to call in an electrician if your dad reset all the breakers. Have him do the exhaust fan too. Let your brother help mom with the cleaning. Forget about doing your own wiring or replacing things yourself. Hire an electrician. The firefighters will thank you.

- Q: Are aluminum sheets suitable for electronic enclosures?

- Certainly, aluminum sheets are a fitting choice for electronic enclosures. Aluminum is extensively employed in the production of these enclosures owing to its exceptional characteristics. It possesses the advantage of being both lightweight and sturdy, ensuring optimal protection for electronic components. Moreover, aluminum exhibits excellent thermal conductivity, effectively dissipating heat generated by electronic devices. Additionally, it is non-magnetic and non-sparking, thereby guaranteeing safety and preventing interference with electronic signals. Furthermore, aluminum can be easily molded, machined, and finished, providing opportunities for customization and aesthetic appeal. All in all, aluminum sheets offer a dependable and cost-efficient solution for electronic enclosures.

Send your message to us

4x8 Brushed Aluminum Sheets for Curtain Wall 1050 1060 H12 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords