Aluminum Sheets Trinidad - 3003 Aluminum Sheet Price from Chinese Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.General Information

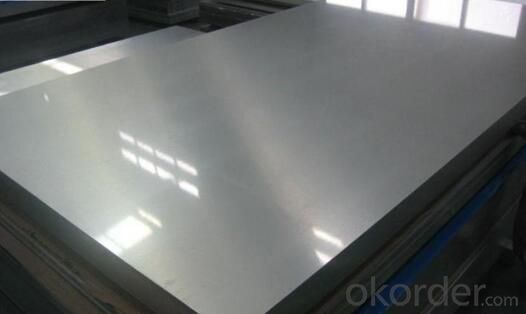

Aluminum sheets is between 0.1 mm and 500mm in thickness and has a wide variety of uses in the construction industry including aluminium siding and roofing. Sheet is also used widely in construction, decoration, transport applications and other various industrial filed, such as automobile body panels, airframes, curtain walls and the hulls of boats etc.

We produces aluminum sheets which meets the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. Our aluminum complying with YS/T 429-2000(Chinese Industry Standard),GB/T 3880,EN485,ASTM B209.

The main producing procedure includes the following steps:

Rolling--Annealing--Slitting--Sawing, Cut-To-Length, Shearing

2. Technical Data

Alloy

AA1050,AA1060, AA1070, AA1100

Temper:

H12, H14, H16, H18, H22, H24, H26, H32,HO, F

Thickness:

0.10-500mm

Aluminum Sheets D.C 3XXXis cut from aluminum coils 3xxx.

Aluminum Sheets D.C 3XXXhas great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Sheets D.C 3XXX is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

3.Main Features of the Aluminum Sheets D.C 3XXX

Superior quality of raw material

Reasonable and stable chemical composition

Accurate tolerance

Goode mechanical property

- Q: Are aluminum sheets suitable for construction purposes?

- Aluminum sheets are indeed appropriate for construction purposes. This material is lightweight and possesses an excellent strength-to-weight ratio, making it an optimal selection for various construction applications. It is resistant to corrosion, has a long-lasting nature, and boasts a high melting point, enabling it to withstand extreme weather conditions and fluctuations in temperature. Furthermore, aluminum sheets can be easily shaped, formed, and fabricated to fulfill specific construction requirements. They are commonly utilized in residential, commercial, and industrial buildings for roofs, wall cladding, window frames, doors, and other structural elements. In conclusion, aluminum sheets provide numerous benefits in the construction field, rendering them a fitting choice for a wide array of construction purposes.

- Q: What are the advantages of using aluminum sheets in the packaging industry?

- There are several advantages of using aluminum sheets in the packaging industry. Firstly, aluminum is a lightweight material, which makes it easier to handle and transport. Secondly, aluminum is highly resistant to corrosion, ensuring the protection of the packaged products. Additionally, aluminum has excellent barrier properties, providing a strong barrier against light, moisture, and oxygen, thus extending the shelf life of the packaged goods. Moreover, aluminum is malleable, allowing for easy shaping and customization of packaging designs. Lastly, aluminum is recyclable, making it a sustainable choice for the packaging industry and contributing to environmental conservation efforts.

- Q: I need to know what composite bats do and how (or if) they are better than aluminum bats.

- one is made of aluminum and one isn't. haha i saw a movie and it had a guy and he said yo man i don't have your money

- Q: What is the weight of aluminum sheets per square foot?

- The weight of aluminum sheets per square foot varies depending on the thickness of the sheet. On average, aluminum sheets weigh around 0.96 pounds per square foot.

- Q: Can aluminum sheet be used for decorative purposes?

- Indeed, aluminum sheet serves as a suitable option for decorative uses. With its adaptability, aluminum can be effortlessly molded, trimmed, and fashioned into an assortment of patterns, rendering it an excellent choice for embellishing ventures. Whether utilized to fashion decorative paneling, sculptures, signage, furnishings, or numerous other ornamental components, aluminum proves itself indispensable. Furthermore, aluminum can be anodized or painted in an extensive array of hues, enabling additional personalization and accentuating its visual allure. Additionally, its lightweight composition and corrosion resistance render it a pragmatic selection for both indoor and outdoor decorative endeavors.

- Q: Can aluminum sheet be used for roofing?

- Yes, aluminum sheet can be used for roofing. Aluminum is a popular choice for roofing due to its numerous advantages. Firstly, aluminum is lightweight, making it easier to install and reducing the load on the structure of the building. Secondly, aluminum is highly durable and resistant to corrosion, which means it can withstand harsh weather conditions, such as heavy rain, snow, and UV radiation. Additionally, aluminum is non-combustible, making it a safe choice for roofing. Furthermore, aluminum is an environmentally friendly material as it is 100% recyclable, reducing its impact on the environment. Overall, aluminum sheet is a reliable and efficient option for roofing applications.

- Q: i have a aluminum bicycle the first time i painted it i painted over the original paint(didnt know any better). The second time i sanded it down with some paint left on it. Now this time im sanding it but im using 60grit it looks good to me is 60 grit to much.

- Home or do-it-yourself spray jobs most of the time come out looking like - fill in word of your choice. Why? Because the person hasn't done their homework in advance. First, you will need to strip the bike down to the bare frame - remove everything. Are you qualified to do all of this? Do you have all the tools needed? The next best step would be to have the frame professionally sand blasted, powder-coated clear coated by possibly an auto body shop that does this kind of thing on the side. Can't do that? Consult Google link below. So much FREE information on the Internet, it's amazing.

- Q: Is it possible to use aluminum sheets in extreme weather conditions, including very hot and very cold temperatures?

- <p>Yes, aluminum sheets can be used in harsh environments, including hot and cold climates. Aluminum is known for its excellent corrosion resistance and durability, making it suitable for various weather conditions. It does not rust and maintains its strength in both low and high temperatures. However, it's important to consider the specific alloy and protective coatings used, as these can affect performance in extreme conditions. Properly treated and coated aluminum can withstand significant temperature fluctuations without significant degradation.</p>

- Q: I am engaged in line cutting, because the cut aluminum plate conductive block wear more fierce, molybdenum wire is often broken card, I do not know that heroes have unique skills, say, we share. Thanks.

- Wire cutting is electrical discharge machining, which is developed on the basis of EDM, punching and forming. In some ways, EDM has been replaced by electrical discharge drilling. The processing object can be as long as the conductive metal parts. Cutting aluminum plate, steel plate effect is basically the same, but the cutting speed is different.

Send your message to us

Aluminum Sheets Trinidad - 3003 Aluminum Sheet Price from Chinese Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords