254SMO stainless steel forgings/round bar/rod/pipe fittings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Stainless steel bars,profiles,beams

Product Information:

(Physical Properties)

Density | 8.24g/cm3 |

Fusion Point | 1320-1390°C |

Standard:ASTM A182 | |

Mechanical Property

Alloy and state | Tensile Strength | Yield Strength | Elongation | Hardness |

RM N/MM2 | RP0.2N/MM2 | A5% | HB | |

Thin plate/strips | >=690 | >=310 | ó=35 | <=223< span=""> |

Sheet | >=655 | >=310 | ó=35 | <=223< span=""> |

254SMO Application field:

1.Petroleum, petrochemical equipment, such as the petrochemical equipment in the corrugated pipe

2. Pulp bleaching equipment, such as pulp digester, bleaching equipment, filter scrubber for bucket cylinder and pressure roller, etc..

3. Power plant flue gas desulfurization device, the main use of the site: absorption tower tower body, flue, block door, inside, spray system, etc..

4.Marine systems or sea water treatment, such as the power plant in the use of seawater cooling of thin walled condensate pipeline, seawater desalination processing equipment, even in the sea may not flow equipment can also be used.

5. Desalination industry, such as salt or desalination equipment

6. Heat exchangers, especially in the working environment of chlorine ion exchanger.

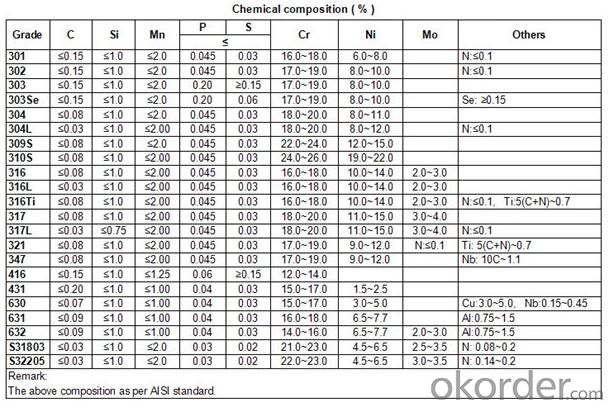

| 200 series: 201, 202 | |

| 300 series: 303, 304, 304L,321, 310S, 316, 316L | |

| 400 series: 410, 420, 430 | |

| Standard | AISI, ASTM, DIN, GB, JIS, SUS |

| Diameter | 2mm-300mm |

| Length | 1 meters to 9 meters or random |

| Surface | bright, black |

| Treatment | Hot rolled, cold drawn, Annealed, Grinding |

| Packing | Standard sea-worthy package or as required |

| Trade Terms | EXW, FOB, CFR, CIF |

| MOQ | 200 KGs Stainless Steel Round Bar |

| Payment | 30% deposit in advance, balance against copy of BL or irrevocable L/C at sight |

| Delivery | Usually 15-20 days upon receipt of deposit for 1 FCL |

Product Size Detail:

| Main operation | Main steel grade | Available size(mm) | Monthly capacity(mt) | Length(mm) | ||

| OEM | Stainless steel | 40~500 | 1500 | 4000~8000 | ||

| Hot | 303 303Cu 304/L 310S 316/L 321 416 420 | 12 ~200 | 3000 | 4000~7000 | ||

| 17-4PH WLA510 | ||||||

| ST Bar | 321 304/L 316/L 310S 17-4PH WLA510 | 19~110 | 2000 | 4000~7000 | ||

CD Bar | Round bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | |

| Square bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| Hex bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| CG Bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | ||

Specificate:

Our Advantages

• All products are made of high-quality imported raw materials.

• Our products are certified by ISO9001:2008 authentication quality systems.

• we are nominated as the AAA enterprise by Jiangsu government.

• Quick Response to Your Enquiry.

- Q: Are stainless steel bars suitable for escalator handrails?

- Yes, stainless steel bars are suitable for escalator handrails. Stainless steel is known for its durability, resistance to corrosion, and ease of maintenance, making it an ideal material choice for high-traffic areas like escalators. Additionally, stainless steel offers a sleek and modern appearance that complements the overall design of escalators.

- Q: Can stainless steel bars be used in mining conveyors?

- Yes, stainless steel bars can be used in mining conveyors. Stainless steel is a durable and corrosion-resistant material, making it suitable for use in harsh mining environments. It has high strength and can withstand heavy loads, making it ideal for use in conveyors that transport heavy materials in mining operations. Stainless steel bars can also resist high temperatures, making them suitable for conveyor systems that operate in hot mining environments. Additionally, stainless steel is easy to clean and maintain, which is important in mining operations where cleanliness and hygiene are crucial. Overall, stainless steel bars are a reliable and efficient choice for use in mining conveyors.

- Q: How do stainless steel bars resist acetic acid?

- Stainless steel bars have a high resistance to acetic acid due to their unique composition and properties. Stainless steel is primarily made of iron, with a minimum of 10.5% chromium content. This chromium forms a passive layer on the surface of the steel, known as chromium oxide, which acts as a protective barrier against corrosion. When acetic acid comes into contact with stainless steel, the chromium oxide layer prevents the acid from reaching the underlying metal. This barrier effectively cuts off the supply of oxygen, water, and other corrosive agents, which are necessary for corrosion to occur. As a result, the stainless steel bars remain highly resistant to the corrosive effects of acetic acid. Additionally, stainless steel bars may contain other alloying elements like nickel and molybdenum, which further enhance their resistance to corrosion. These elements increase the stability of the passive layer and provide additional protection against chemical attacks, including acetic acid. Overall, the corrosion resistance of stainless steel bars to acetic acid makes them suitable for various applications where they may come into contact with this acid, such as in chemical processing equipment, food and beverage industry, and pharmaceutical manufacturing.

- Q: Do stainless steel bars have good corrosion resistance in acidic environments?

- Stainless steel bars exhibit remarkable resistance to corrosion when placed in acidic environments. The corrosion-resistant nature of stainless steel is widely recognized, and this feature is further amplified through the inclusion of chromium. The addition of chromium creates a shielding coating called chromium oxide, which serves as a formidable barrier against the destructive impact of acids. Consequently, stainless steel bars are extensively employed in sectors like chemical processing, oil and gas, and food processing, where exposure to acidic surroundings is prevalent.

- Q: Can stainless steel bars be used in construction equipment production?

- Yes, stainless steel bars can indeed be used in construction equipment production. Stainless steel is a versatile and durable material that offers various benefits for construction equipment. It has excellent corrosion resistance, which is crucial for outdoor equipment that is exposed to harsh weather conditions and moisture. Stainless steel also has high strength and toughness properties, making it suitable for heavy-duty machinery and equipment that require robustness and reliability. Additionally, stainless steel bars can be easily fabricated and welded to meet specific design requirements, allowing for flexibility in construction equipment production.

- Q: What is the difference between stainless steel bars and stainless steel rods?

- Stainless steel bars and stainless steel rods share many similarities, but there are several distinct contrasts between them. To begin with, the most noticeable distinction is their shape. Stainless steel bars are elongated, straight, and rectangular, resembling beams or bars. They maintain a consistent width and thickness throughout their length. Conversely, stainless steel rods are cylindrical and maintain a uniform diameter from end to end. Another difference lies in their common applications. Stainless steel bars find frequent use in construction, engineering, and industrial projects where strength and durability are crucial. They serve as structural supports, frame materials, and components in machinery. Conversely, stainless steel rods are commonly employed in applications that demand precision and tight tolerances. They are frequently utilized in the production of screws, bolts, valves, and other small components. Regarding availability and manufacturing processes, stainless steel bars are generally produced in larger sizes and lengths, while stainless steel rods are obtainable in smaller diameters and lengths. Both are manufactured via hot rolling or cold drawing processes, but rods are typically cold drawn to achieve their precise dimensions. Lastly, there is a disparity in cost between stainless steel bars and rods. Due to their larger size and greater weight, stainless steel bars generally carry a higher price tag than rods. Additionally, the specific alloy and grade of stainless steel employed can influence the price difference. In summary, the primary disparities between stainless steel bars and stainless steel rods lie in their shape, applications, availability, manufacturing processes, and cost. Bars are rectangular and utilized in construction and industrial projects, while rods are cylindrical and commonly used for precision components.

- Q: Are stainless steel bars resistant to UV radiation?

- Generally, stainless steel bars are resistant to UV radiation. They possess excellent corrosion resistance, which includes protection against oxidation caused by UV radiation from the sun. The presence of at least 10.5% chromium in stainless steel forms a protective layer on the material's surface when it comes into contact with oxygen. This protective layer, referred to as a passive film, acts as a barrier against harmful substances, including UV radiation. Consequently, stainless steel bars can endure prolonged exposure to sunlight without experiencing significant degradation or discoloration. Nevertheless, it is important to note that the level of resistance may differ depending on the specific grade of stainless steel and the intensity of the UV radiation.

- Q: How do you determine the quality of stainless steel bars?

- To determine the quality of stainless steel bars, various factors need to be considered. These include assessing the grade and composition of the stainless steel, inspecting its surface finish and appearance for any imperfections or defects, checking for accurate dimensions and tolerances, and ensuring it meets relevant industry standards and specifications. Additionally, conducting mechanical tests such as hardness, tensile strength, and corrosion resistance evaluations can help determine the overall quality and performance of stainless steel bars.

- Q: How much temperature would you like to burn the stainless steel bar red?

- The metal will has 680 degrees, 960 degrees of dark redOrange 1100 colors, when the temperature exceeds 1300 degrees, will appear incandescent.

- Q: Can stainless steel bars be used in the automotive repair industry?

- The automotive repair industry can utilize stainless steel bars. Stainless steel is a versatile and durable material that offers numerous advantages in automotive repair applications. To begin with, stainless steel bars possess high resistance to corrosion, making them an ideal choice for automotive repair where exposure to chemicals, moisture, and other corrosive elements is common. This corrosion resistance ensures the bars' structural integrity and aesthetics remain intact over time, thereby improving the longevity and performance of repaired automotive parts. Furthermore, stainless steel bars exhibit exceptional strength and durability, which are vital qualities in the automotive repair industry. They can withstand heavy loads, impacts, and vibrations, making them suitable for reinforcing and repairing various automotive components such as frames, exhaust systems, suspension parts, and body panels. Moreover, stainless steel bars offer excellent heat resistance, enabling them to withstand elevated temperatures without warping or losing their strength. This characteristic makes them suitable for automotive repair applications involving exposure to high temperatures, such as engine components, exhaust systems, and heat shields. Additionally, stainless steel bars are relatively easy to manipulate as they can be cut, welded, and formed into desired shapes. This flexibility allows automotive repair technicians to customize the bars to meet specific repair requirements, ensuring precise and effective repairs. In conclusion, stainless steel bars are a valuable asset in the automotive repair industry due to their corrosion resistance, strength, durability, heat resistance, and versatility. By utilizing stainless steel bars, automotive repair professionals can enhance the overall quality and reliability of repaired vehicles, performing their tasks effectively and efficiently.

Send your message to us

254SMO stainless steel forgings/round bar/rod/pipe fittings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords