20x40mm Aluminum Profiles for Electric Power Engineering Sector

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminum Extrusion for Electric Power Engineering Sector Description

Aluminum Extrusion for Electric Power Engineering Sector is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminum Extrusion for Electric Power Engineering Sector

Aluminum Extrusion for Electric Power Engineering Sector | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminum Extrusion for Electric Power Engineering Sector

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminum Extrusion for Electric Power Engineering Sector

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminum Extrusion for Electric Power Engineering Sector

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

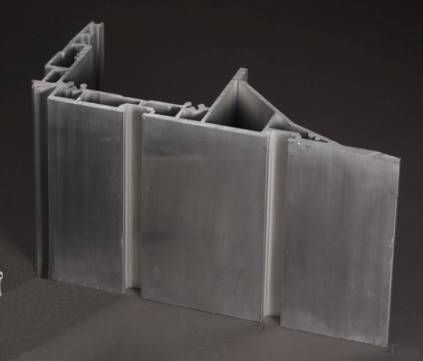

6. Image of Aluminum Extrusion for Electric Power Engineering Sector

7. Package and shipping of Aluminum Extrusion for Electric Power Engineering Sector

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the different finishing options available for aluminum profiles?

- The different finishing options available for aluminum profiles include anodizing, powder coating, painting, polishing, brushing, and sandblasting. These options allow for customization in terms of color, texture, and durability. Anodizing provides a protective layer and can be done in various colors. Powder coating offers a wide range of colors and a durable finish. Painting allows for custom colors and designs. Polishing creates a smooth and reflective surface. Brushing creates a brushed metal look. Sandblasting adds texture and can create a matte or satin finish. Overall, these finishing options enhance the aesthetics and functionality of aluminum profiles.

- Q: Can aluminum profiles be used for solar panel installations?

- Yes, aluminum profiles can be used for solar panel installations. Aluminum is a commonly used material in the construction industry due to its lightweight, durability, and resistance to corrosion. These characteristics make it an ideal choice for supporting and mounting solar panels. Aluminum profiles can be easily fabricated and customized to fit specific installation requirements, such as roof or ground mounting systems. Moreover, aluminum has excellent thermal conductivity, allowing for efficient heat dissipation from the solar panels, which is crucial for maintaining their performance and lifespan. Additionally, aluminum profiles are often used for framing solar panels, providing structural support and ensuring their stability in various weather conditions. Overall, aluminum profiles are a popular choice for solar panel installations due to their strength, longevity, and adaptability.

- Q: Can aluminum profiles be utilized in constructing building facades that necessitate superior thermal insulation?

- <p>Yes, aluminum profiles can be used for building facades requiring high levels of insulation. By incorporating thermal breaks or using insulated aluminum profiles, the thermal conductivity of aluminum can be mitigated. These profiles can also be combined with insulating materials like polyurethane or mineral wool to enhance the insulation properties. Modern facade systems often employ aluminum due to its strength, durability, and design flexibility, while ensuring energy efficiency through advanced insulation techniques.</p>

- Q: This question asks about the various applications of aluminum extrusions within the automotive manufacturing industry.

- <p>Aluminum extrusions are widely used in automotive manufacturing due to their lightweight, high strength, and corrosion resistance. They are utilized in several areas: 1) Structural components such as chassis, frames, and body parts to reduce vehicle weight and improve fuel efficiency. 2) Engine components to enhance engine performance and durability. 3) Heat exchangers and radiators for effective cooling systems. 4) Crash management systems to absorb impact during collisions. 5) Interior components like dashboards and door panels for lightweight and aesthetic appeal. 6) Electrical components such as battery casings and wiring harnesses. 7) Wheels and suspension components for improved handling and reduced unsprung weight. These applications contribute to the overall performance, safety, and efficiency of vehicles.</p>

- Q: Is it possible to utilize aluminum profiles in interior design projects?

- <p>Yes, aluminum profiles can be used for interior design. They are popular for their strength, durability, and modern aesthetic. Aluminum profiles are lightweight, easy to install, and resistant to corrosion, making them suitable for various applications such as window frames, door frames, shelving systems, and decorative elements. They can be powder-coated or anodized to achieve different colors and finishes, allowing for a wide range of design flexibility.</p>

- Q: How do you cut aluminum profiles?

- To cut aluminum profiles, there are a few methods you can use depending on the tools and equipment available to you. Here are three commonly used methods: 1. Power saw: A power saw, such as a miter saw or circular saw with a carbide-tipped blade specifically designed for cutting metal, is an effective way to cut aluminum profiles. Set the blade to the appropriate speed and angle for your desired cut, and slowly guide the saw through the profile, ensuring a smooth and accurate cut. 2. Hacksaw: If you don't have access to power tools, a hacksaw is an inexpensive and accessible option. Choose a fine-toothed blade designed for cutting metal and securely clamp the aluminum profile in a vice or workbench. Use long, steady strokes to cut through the profile, applying gentle pressure to maintain control and prevent the blade from binding. 3. Shearing: For thinner aluminum profiles, a manual shear can be used to make straight cuts. Place the profile into the shear, aligning the cutting edge with the desired cut line, and apply steady pressure to the handle, allowing the shear to slice through the aluminum. This method is ideal for cutting thinner profiles with precision and minimal risk of distortion. Regardless of the method you choose, it's important to wear appropriate safety equipment, such as safety glasses and gloves, to protect yourself from metal shavings and sharp edges. Additionally, always measure and mark your cut line accurately before beginning to ensure the desired result.

- Q: Are aluminum profiles suitable for use in chemical processing environments?

- Yes, aluminum profiles are generally suitable for use in chemical processing environments. Aluminum has excellent corrosion resistance properties and can withstand various chemicals, acids, and bases. Additionally, aluminum profiles can be further enhanced with protective coatings or anodization to provide even greater resistance to chemical exposure. However, the suitability may depend on the specific chemicals and conditions involved, so it is important to consult with experts or suppliers to ensure the best choice of aluminum profiles for a particular chemical processing environment.

- Q: Are aluminum profiles recyclable multiple times? If yes, explain the process.

- <p>Yes, aluminum profiles can be recycled multiple times. The recycling process for aluminum involves melting the scrap aluminum, which requires only 5% of the energy needed to produce new aluminum from raw materials. After collection, aluminum profiles are sorted, cleaned, and shredded into small pieces. These pieces are then melted in a furnace and cast into new ingots or billets. From there, they can be rolled, extruded, or forged into new aluminum products. This cycle can be repeated indefinitely without loss of quality, making aluminum one of the most sustainable materials.</p>

- Q: What are the different surface engraving or etching techniques for aluminum profiles?

- There are several surface engraving or etching techniques available for aluminum profiles, each offering unique benefits and results. Some of the commonly used techniques include: 1. Chemical Etching: This process involves the use of chemicals to selectively remove the top layer of the aluminum profile. It allows for precise and intricate designs to be etched onto the surface, making it suitable for decorative purposes. 2. Laser Engraving: Laser engraving utilizes a high-powered laser beam to vaporize the aluminum surface, creating a permanent etching. This technique offers excellent precision, allowing for detailed designs and logos to be engraved onto the profile. 3. Mechanical Engraving: Mechanical engraving involves the use of rotary cutters or diamond-tipped tools to physically engrave the surface of the aluminum profile. This technique is commonly used for industrial applications, such as marking product codes or serial numbers. 4. Electrochemical Etching: This technique uses an electric current and an electrolyte solution to etch the aluminum surface. It is commonly employed for creating durable and legible markings, such as product labels or identification codes. 5. Sandblasting: Sandblasting involves directing a stream of abrasive particles at high speed onto the aluminum surface. This process removes the top layer of the material, leaving a textured or frosted appearance. Sandblasting is often used for decorative purposes or to create a matte finish. 6. Acid Etching: Acid etching utilizes an acid solution to selectively remove the top layer of the aluminum surface. This technique is commonly used for creating a matte or satin finish, as well as for creating patterns or textures on the profile. These engraving and etching techniques offer a wide range of options for aluminum profiles, allowing for customization, branding, or functional purposes. The choice of technique depends on factors such as the desired design, level of detail, durability requirements, and the intended application of the aluminum profile.

- Q: What are the differences between aluminium profiles 6063 and 6463?

- 6063 aluminum introduction: Standard: GB/T 3191-1998, commodity name: 6063 aluminum bar, 6063 aluminum alloy bar.6063 aluminum alloy is a moderate strength heat treatment alloy in AL-Mg-Si system.

Send your message to us

20x40mm Aluminum Profiles for Electric Power Engineering Sector

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords