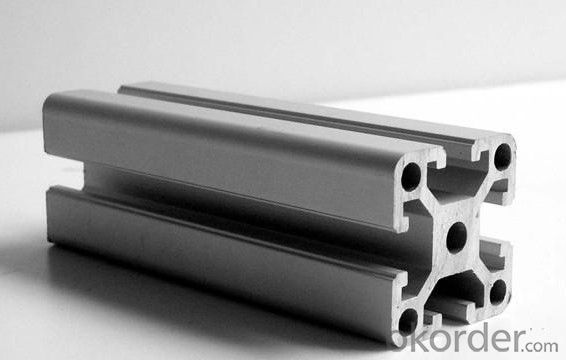

2020 T Slot Aluminum Profiles Extrusion - Aluminium Industrial Profile Hot Selling

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.5

- Supply Capability:

- 0.5 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

aluminium industrial profile

used on the industrial,we extrude these profile very well.

Industial Aluminum Profile

Alloy: 6063, Temper: T5, T6.

surface:mill finished,anodized3.

widely used for building,furniture,transportation

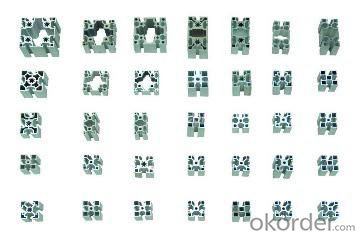

Industial Aluminum Profile

Alloy: 6063,

Temper: T5, T6.

building,furniture,transportation,machine

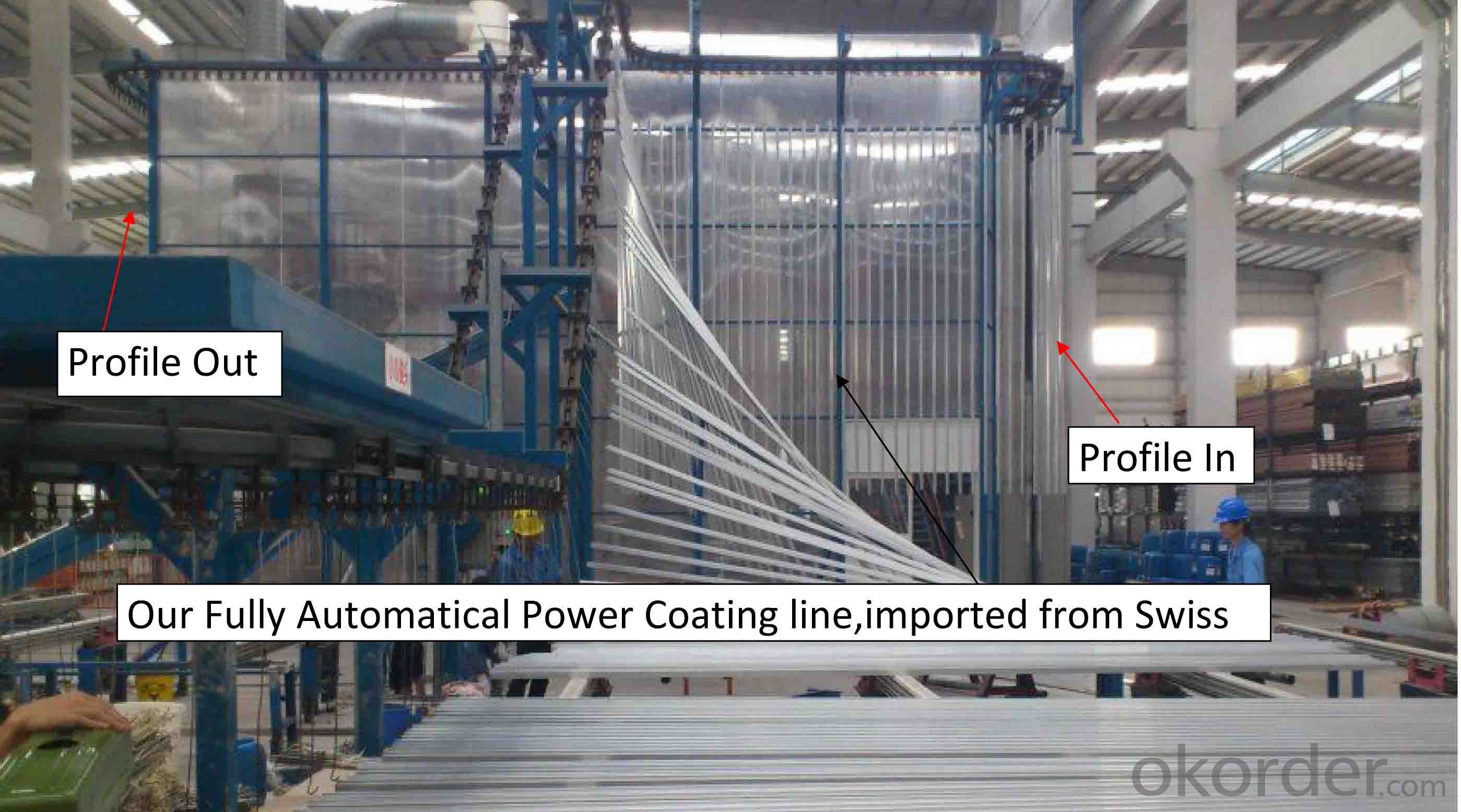

Anodized silver, anodized champagne, anodized bronze, anodized black, powder coated, electrophoresis, polished, Thermal break, wooden grain.

Length: 5.8---6 meters, depend on customers' requested.

Packing: kraft paper, carton, or on customers' requested.

Exported to different countries worldwide.

- Q: This question asks about the variety of colors offered for aluminum profiles used in exterior siding and trim applications.

- <p>Aluminum profiles for siding and trimming are available in a wide range of colors to suit various architectural styles and design preferences. Common colors include white, black, brown, beige, and gray, which are popular for their neutrality and versatility. Additionally, there are bolder options such as red, blue, green, and yellow for more distinctive looks. Some manufacturers also offer custom color matching services for specific projects. The finishes can be powder-coated or anodized, providing durability and resistance to weathering. It's always best to check with specific manufacturers for the most up-to-date color offerings as they may introduce new colors or discontinue others based on market trends.</p>

- Q: What are the various types of connectors that can be used with aluminum profiles?

- <p>Aluminum profiles can be connected using a variety of connectors designed for different applications and structural needs. Common types include: 1. T-slots connectors, which slide into the T-slots of the profiles for secure attachment. 2. Angle connectors, used to join profiles at right angles. 3. Corner brackets, for creating 90-degree corners. 4. Clamping blocks, which hold profiles together without screws. 5. Hinges, allowing for pivoting movements. 6. End caps, to cover the ends of profiles. 7. Cylindrical connectors, for joining round tubes. 8. Linear connectors, for straight-line connections. 9. Specialized connectors for specific applications, such as cable management or mounting brackets. These connectors are crucial for assembling aluminum profile systems in various configurations.</p>

- Q: What are the surface finishes available for aluminum profiles?

- Some common surface finishes available for aluminum profiles include anodizing, powder coating, polishing, brushing, and chemical etching.

- Q: Are there any specific safety precautions when working with aluminum profiles?

- Yes, there are specific safety precautions when working with aluminum profiles. These include wearing appropriate personal protective equipment such as gloves, safety glasses, and hearing protection. It is also important to ensure proper ventilation in the workspace to prevent inhalation of aluminum dust or fumes. Additionally, precautions should be taken to avoid sharp edges and use proper lifting techniques to prevent injury.

- Q: This question asks for an explanation of the various types of aluminum profiles that are specifically used in the manufacturing and construction of windows and doors.

- <p>Aluminum profiles for windows and doors come in various types, each serving specific functions and designs. Common types include: 1) Casement profiles, used for side frames and meeting stiles in casement windows; 2) Mullion profiles, for vertical and horizontal structural members in window walls; 3) Transom profiles, used in the top or bottom of windows to support glazing; 4) Sash profiles, forming the main frame of the window sash; 5) Threshold profiles, used at the bottom of doors for weather sealing; 6) Header profiles, supporting the top of a door or window opening; and 7) Specialty profiles, designed for specific architectural needs like corner posts or decorative elements. Each profile is engineered for strength, durability, and compatibility with glazing and浜旈噾閰嶄欢.</p>

- Q: How do aluminum profiles contribute to sustainable infrastructure development?

- Various ways exist in which aluminum profiles contribute significantly to the promotion of sustainable infrastructure development. To begin with, aluminum, being a lightweight material, requires less energy for transportation and installation when compared to heavier materials like steel. Consequently, this reduces greenhouse gas emissions and the overall carbon footprint associated with construction projects. In addition, aluminum profiles possess exceptional durability and corrosion resistance, enabling them to withstand harsh environmental conditions and prolong the lifespan of infrastructure projects. As a result, the frequency of repairs and replacements is reduced, leading to a decrease in waste generation and resource consumption. Moreover, aluminum is a material highly amenable to recycling, as it can be recycled infinitely without losing its original properties. This fosters a circular economy by minimizing the necessity for primary aluminum production and reducing the demand for raw materials. Additionally, the recycling process for aluminum requires significantly less energy compared to primary production, resulting in decreased energy consumption and lower emissions. Furthermore, aluminum profiles offer design flexibility and compatibility with diverse construction methods, thereby permitting the implementation of innovative and sustainable infrastructure solutions. They can be readily integrated into energy-efficient systems, such as solar panels or LED lighting, to further enhance sustainability. On the whole, the incorporation of aluminum profiles in infrastructure development contributes to the creation of a more sustainable built environment by reducing energy consumption, minimizing waste generation, promoting recycling, and enabling the implementation of energy-efficient solutions.

- Q: What are the potential hazards or risks associated with the use of aluminum profiles in construction projects?

- <p>Safety concerns related to using aluminum profiles in construction include potential corrosion due to exposure to harsh weather conditions, risk of electrical conductivity which may lead to electrocution hazards, and the possibility of thermal expansion and contraction causing structural instability. Additionally, improper installation can lead to structural failure, and the lightweight nature of aluminum may not provide sufficient strength in load-bearing applications. It's crucial to ensure proper design, quality materials, and adherence to safety standards to mitigate these risks.</p>

- Q: How do you prevent galvanic corrosion in marine environments with aluminum profiles?

- One way to prevent galvanic corrosion in marine environments with aluminum profiles is by using sacrificial anodes made of a different, more active metal. These anodes, typically made of zinc or magnesium, are connected to the aluminum profiles and act as a sacrificial material that corrodes instead of the aluminum. This helps in protecting the aluminum profiles from galvanic corrosion. Additionally, proper insulation and coating of the aluminum profiles can also be effective in preventing direct contact with other metals and reducing the risk of galvanic corrosion.

- Q: Can aluminum profiles be used in telecommunications infrastructure?

- Yes, aluminum profiles can be used in telecommunications infrastructure. Aluminum is a lightweight and durable material that offers excellent structural integrity and corrosion resistance, making it suitable for various applications within telecommunications infrastructure, such as antenna towers, cable trays, and equipment racks. Additionally, aluminum profiles can be easily customized and fabricated to meet specific requirements, making them a versatile choice for telecom installations.

- Q: Are aluminum profiles suitable for balcony railings?

- Yes, aluminum profiles are suitable for balcony railings. Aluminum is a popular material choice for balcony railings due to its durability, strength, and low maintenance requirements. It is resistant to rust and corrosion, making it highly suitable for outdoor use. Additionally, aluminum profiles can be easily customized and shaped to fit any design preference or architectural style. They are lightweight, yet sturdy enough to provide the necessary support and safety for balcony railings. Aluminum railings are also available in a variety of finishes and colors, allowing for endless design possibilities. Overall, aluminum profiles are a reliable and stylish option for balcony railings.

Send your message to us

2020 T Slot Aluminum Profiles Extrusion - Aluminium Industrial Profile Hot Selling

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.5

- Supply Capability:

- 0.5 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords