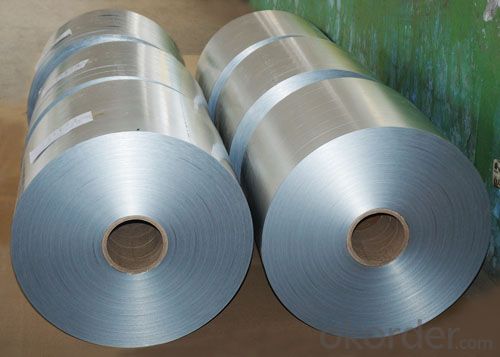

APV 25 Aluminum Coil 1100 1200 O H14 H24 Mill Finish

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1100 1200 O H14 H24 Mill Finish Aluminium Coil

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above

3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment.

6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications.

Description

item | 1050 1060 1100 3003 Aluminum coil | |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

Material | 1060,1050,1100 3003,3103,3004,3005,3105 5052, 5454,5754 | |

Size | Thickness | 0.5mm-3.5mm |

Width | 800-1500mm | |

Weight/Roll | About 1.5MT/3MT | |

Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. | |

Surface | Bright, polished, hair line, brush, checkered, embossed, etc | |

Trade terms | Price term | ,FOB, CNF, CIF, etc |

Payment Term | TT,L/C | |

MOQ | 2MT | |

20 GP Capacity | About 20-25MT | |

Delivery time | 1.The products will delivery immediately after receiving the payment. 2.According to the order quantity, prompt delivery. | |

Export to | Ireland,Singapore,Indonesia,Ukraine,Spain,Canada,USA,Brazil,Thailand,Korea,Iran,India,Egypt,Kuwait, Oman,Viet Nam, South Africa, Dubai, Russia, etc | |

Package | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | |

Application | 1)Further making utensil.2)Solar reflective film3)The appearance of the building4)Interior decorating:ceilings,walls,etc.5)Furniture cabinets6)Elevator decoraction7)Signs,nameplate,bags making.8)Decoration inside and outside the car9)Household appliances:refrigerators,microwave ovens,audio equipment,etc.10)The consumer electronics:mobile phones,digital cameras,MP3,etc. | |

- Q: What are the potential applications of laminated aluminum coils?

- Laminated aluminum coils have a wide range of potential applications. They can be used in industries such as electrical, automotive, aerospace, and construction. Some specific applications include electrical transformers, heat exchangers, automotive radiators, air conditioning systems, and architectural facades. The lamination process enhances the durability, heat and corrosion resistance, and electrical conductivity of the coils, making them suitable for various demanding environments and applications.

- Q: What are the different coil diameters available for aluminum coils?

- The coil diameters for aluminum coils can differ based on specific needs and applications. Typically, aluminum coils are offered in various diameters to accommodate different requirements. These diameters can vary from a few inches to several feet. Manufacturers and suppliers may have different options for coil diameters. It is crucial to consider that the chosen diameter will affect factors like coil weight, handling, and compatibility with machinery or equipment. Therefore, it is recommended to consult with suppliers or manufacturers to determine the available coil diameter options for aluminum coils based on intended use and requirements.

- Q: Are there any limitations to the minimum coil width of aluminum coils?

- Yes, there are limitations to the minimum coil width of aluminum coils. The minimum coil width is determined by various factors, including the manufacturing process and the equipment used. Generally, the coil width is limited by the capabilities of the rolling mill or other processing machinery. The minimum coil width is typically determined by the size of the rolls or mandrels used in the production process. If the coil width is too narrow, it may cause issues with the stability and integrity of the coil, making it more difficult to handle and transport. Additionally, a narrower coil width may also affect the overall efficiency of the manufacturing process. Therefore, it is important to consider these limitations when determining the minimum coil width for aluminum coils.

- Q: Explain the differences between aluminum coil and aluminum sheet in a few sentences.

- <p>Aluminum coil and aluminum sheet are both flat aluminum products but differ in form and usage. Aluminum coil is a long, continuous roll of aluminum that can be easily unrolled and cut to length, making it ideal for manufacturing processes where the material needs to be fed through machines. It is commonly used in industries such as construction, packaging, and automotive for applications like roofing, siding, and food packaging. Aluminum sheet, on the other hand, comes in flat, rectangular pieces with specific dimensions and is typically thicker than coil. It is used in applications where a solid, non-continuous piece is required, such as in signage, furniture, and decorative elements. The thickness and surface finish can also vary between coils and sheets, with sheets often being available in a wider range of finishes and thicknesses.</p>

- Q: How are aluminum coils used in the manufacturing of household appliances?

- Aluminum coils are used in the manufacturing of household appliances as they provide excellent conductivity, durability, and corrosion resistance. These coils are commonly used in appliances such as refrigerators, air conditioners, and heating systems. They help in transferring heat efficiently, improving energy efficiency, and ensuring the longevity of the appliance. Additionally, aluminum coils are lightweight, making them easier to handle during the manufacturing process.

- Q: Can aluminum coils be used in the production of architectural façades?

- Yes, aluminum coils can be used in the production of architectural façades. Aluminum is a popular choice for façades due to its lightweight nature, durability, and versatility. Aluminum coils can be easily formed and shaped to create various architectural designs, making them suitable for use in the construction of façades.

- Q: What is the typical fatigue strength of aluminum coils?

- The fatigue strength of aluminum coils can vary depending on several factors, such as the alloy composition, heat treatment, manufacturing process, and the specific application. However, compared to other metals like steel, aluminum is generally known to have relatively low fatigue strength. Typically, the fatigue strength of aluminum coils falls within the range of 30% to 50% of their ultimate tensile strength (UTS). This means that the fatigue limit or endurance limit of aluminum coils is usually less than half of their maximum strength. It is worth noting that factors such as surface defects, stress concentrations, and environmental conditions like temperature and humidity can also affect the fatigue strength of aluminum coils. These factors can further decrease the fatigue strength of aluminum coils. Hence, when designing and using aluminum coils in applications where fatigue is a concern, it is crucial to consider the specific alloy and processing conditions. Additionally, implementing suitable design practices and maintenance procedures is vital to mitigate the risk of fatigue failure.

- Q: Can aluminum coils be used in the production of aircraft fuel tanks?

- Yes, aluminum coils can be used in the production of aircraft fuel tanks. Aluminum is a commonly used material in the aerospace industry due to its lightweight, strong, and corrosion-resistant properties. It is an ideal choice for fuel tanks as it can effectively withstand the harsh conditions and requirements of aircraft operations.

- Q: I did a activity series lab and on my data table, it shows that lead reacted more than aluminum did, but aluminum is more active than lead. So, why does it show that lead is more active when it really isn't? Is it human error?

- Aluminum is more active than lead. You should double check your activity data table. If you confirm that the table says that lead is more active than aluminum, the table is in error.

- Q: What are the common safety precautions when working with aluminum coils?

- When working with aluminum coils, it is important to follow several safety precautions to ensure the well-being of individuals and prevent accidents. Some common safety precautions when working with aluminum coils include: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE such as safety goggles, gloves, and aprons when handling aluminum coils. This protective gear helps protect against potential injury from sharp edges, cuts, or burns. 2. Proper Handling Techniques: Use proper lifting techniques to avoid strain or injury. Aluminum coils can be heavy, so it is essential to lift with your legs, not your back, and use lifting aids or equipment if necessary. 3. Secure Storage: Store aluminum coils securely to prevent them from falling or rolling. Avoid stacking coils too high to prevent them from toppling over and causing injuries. 4. Proper Ventilation: Ensure that the work area has adequate ventilation to prevent the buildup of fumes or dust particles. Aluminum coils may release harmful particles or gases when cut or processed, so proper ventilation is crucial for maintaining a safe working environment. 5. Fire Safety: Aluminum is highly flammable, so it is vital to prevent sparks or open flames near aluminum coils. Use non-sparking tools and avoid smoking or using flammable materials in the vicinity. 6. Sharp Edges: Be cautious of sharp edges on aluminum coils, as they can cause cuts or lacerations. Handle coils with care and use appropriate tools to mitigate the risk of injury. 7. Training and Safety Guidelines: Ensure that all personnel working with aluminum coils are properly trained in handling procedures and safety guidelines. This includes understanding the correct use of equipment, emergency procedures, and knowledge of any specific hazards associated with aluminum coil handling. 8. Regular Maintenance: Maintain equipment and tools regularly to ensure they are in good working condition. This includes inspecting and repairing any damaged or worn-out parts that could pose a safety risk. 9. First Aid and Emergency Response: Keep a well-equipped first aid kit nearby and ensure that employees are aware of its location. In addition, establish clear emergency response protocols and train employees on what to do in case of an accident or injury. By adhering to these common safety precautions, individuals can minimize the risks associated with working with aluminum coils and create a safer working environment.

Send your message to us

APV 25 Aluminum Coil 1100 1200 O H14 H24 Mill Finish

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords