1.0-6.0mm Thickness Aluminum Patio Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

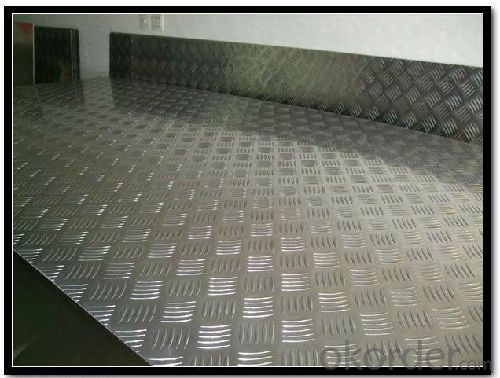

Aluminum tread sheet

1)Free sample available.

2)Manufacturer.

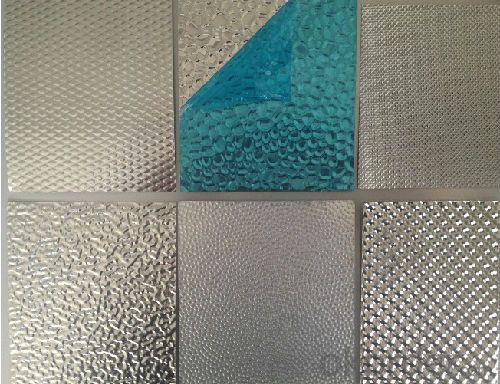

3)Different designs.

4)ISO 9001 and CE passed.

Specification

| Product | aluminum tread sheet |

| Alloy | 1050 1060 1100 3003 3004 5083 5754 |

| Temper | H12 H14 H16 H18 H22 H24 H26 H28 H112 |

| Thickness | 0.1-3.0 mm |

| Width | 8-2200 mm |

| Application | Regularly used in ships, vessels, vehicles, timber, automotive and aircraft panels welded, pressure should be strictly fireproof containers, refrigeration equipment, tower, drilling equipment, transportation equipment, missile components, armor, etc. |

| Certification | ISO 9001 and CE passed. |

| Welcome to visit our factory! | |

Packaging & Delivery

| Packaging Details: | aluminum tread sheet Standard seaworthy wooden case or pallet,and with pvc film inside |

| Delivery Detail: | 20 days upon receiving the deposit for embossed aluminum shee |

- Q: Are aluminum sheets suitable for outdoor use?

- Indeed, aluminum sheets are well-suited for utilization outdoors. With its exceptional durability and resistance to corrosion, aluminum emerges as an optimal material for outdoor purposes. Despite its lightweight nature, aluminum exhibits remarkable strength, enabling it to endure severe weather conditions including rainfall, snowfall, and the harmful effects of UV radiation. Furthermore, aluminum sheets can be coated or painted, amplifying their resistance to corrosion and furnishing supplementary safeguarding against environmental elements. Consequently, aluminum sheets have garnered significant popularity in the domain of outdoor construction, signage, roofing, and various other exterior applications where endurance and longevity are paramount.

- Q: This question asks about the various types of paint that can be used specifically for aluminum sheets, indicating an interest in paint compatibility and options for this particular material.

- <p>There are several types of paints suitable for aluminum sheets, each offering unique properties. These include: 1. Acrylic Paints - Water-based, easy to apply, and offer good adhesion. 2. Epoxy Paints - Known for their durability and chemical resistance, they provide a strong bond to the metal. 3. Enamel Paints - Provide a hard, glossy finish and are resistant to chipping and scratching. 4. Polyester Paints - Offer excellent durability and UV resistance, making them suitable for exterior applications. 5. Powder Coatings - Applied electrostatically, they provide a tough, scratch-resistant finish. 6. Specialty Paints - Such as heat-resistant or anti-corrosive paints, designed for specific industrial applications. The choice of paint depends on the application, desired finish, and environmental conditions.</p>

- Q: Are aluminum sheets suitable for use in marine or saltwater environments?

- Yes, aluminum sheets are suitable for use in marine or saltwater environments. Aluminum has excellent corrosion resistance properties and is known for its ability to withstand the harsh conditions found in marine environments. Unlike many other metals, aluminum forms a protective oxide layer on its surface when exposed to oxygen, which helps prevent further corrosion. This oxide layer acts as a barrier, protecting the underlying metal from saltwater and other corrosive elements. Additionally, aluminum is lightweight yet strong, making it an ideal choice for marine applications where weight reduction is important. It is commonly used in the construction of boats, ships, offshore structures, and other marine equipment.

- Q: What are the different surface finishes for aluminum sheets in the automotive industry?

- The different surface finishes for aluminum sheets in the automotive industry include mill finish, anodized finish, and painted finish. Mill finish refers to the untreated surface of aluminum sheets, which typically has a matte appearance. Anodized finish involves an electrochemical process that creates a protective layer on the surface of aluminum, enhancing its resistance to corrosion and increasing its durability. Painted finish involves applying a layer of paint onto the aluminum sheet, providing both aesthetic appeal and additional protection against the elements.

- Q: Other then pop cans, what else is aluminum that can be recycled?

- all of it.

- Q: Are aluminum sheets suitable for harsh weather conditions?

- Aluminum sheets are highly suitable for harsh weather conditions due to their exceptional properties. Aluminum is a lightweight yet durable material that offers excellent resistance against corrosion, rust, and UV radiation. This makes it particularly resilient against the damaging effects of extreme weather conditions such as heavy rain, snow, high winds, and intense sunlight. Furthermore, aluminum has a high strength-to-weight ratio, allowing it to withstand the pressure exerted by severe weather without sustaining significant damage. Additionally, aluminum sheets can be coated with protective finishes such as anodization or powder coating, further enhancing their ability to withstand harsh climates. Overall, aluminum sheets are an excellent choice for applications requiring resilience in harsh weather conditions.

- Q: Are aluminum sheets suitable for food contact applications?

- Aluminum sheets are indeed appropriate for food contact purposes. The food industry extensively employs aluminum because of its diverse advantageous characteristics. It is non-hazardous, non-responsive, and resistant to corrosion, thereby ensuring that it is safe to use alongside food. Aluminum sheets can be effortlessly molded into various shapes and sizes, rendering them suitable for a broad array of food packaging and cooking uses. Moreover, aluminum boasts exceptional thermal conductivity, facilitating efficient heat transfer during the cooking or baking process. It is also impervious to light, moisture, and oxygen, creating a protective barrier that preserves the freshness and quality of food. In general, due to their safety, adaptability, and durability, aluminum sheets are a highly favored option for food contact applications.

- Q: What is the thermal conductivity of 101 aluminum sheets?

- The thermal conductivity of 101 aluminum sheets is influenced by several factors, including sheet thickness, aluminum purity, and measurement temperature. Typically, aluminum exhibits a significant thermal conductivity, varying from 205 to 250 watts per meter kelvin (W/mK). Nevertheless, it is recommended to consult specific technical data or liaise with a manufacturer for precise information regarding the thermal conductivity of 101 aluminum sheets.

- Q: Could ring-pull can be transformed as aluminum sheet?

- Yes

- Q: is steel better for making bicycle frames.....how does it differ from the aluminum framed bikes?

- It depends on the type of riding you do. If you ride long distance you don't want aluminum, it is very stiff and will wear out your body with jolts from the road. Steel provides some degree of flex, which softens road jolts. You might want to go to a bike shop and hold a steel bike and alum bike so you can appreciate the difference in weight. Another thing about alum bikes is they do suffer from metal fatigue, so they will not last for 20 years like a steel bike (perhaps even much less depending on usage).

Send your message to us

1.0-6.0mm Thickness Aluminum Patio Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords