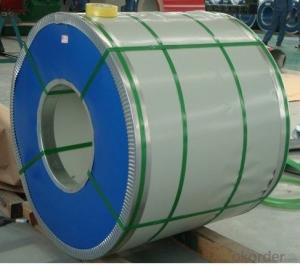

0.12mm-1.3mm Thickness Prepainted Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Surface Treatment:Galvanized

Certification:ISO, SGS

Technique:Cold Rolled

Standard:ASTM, JIS, AISI, DIN

Application:Container Plate

Edge:Slit edge

Stock:Stock

Steel Grade:Q235B

Thickness:0.12mm-3.0mm

Coil Weight:3-8 Tons

Gloss:65%-80%

Export Markets:Global

ID:508mm

Zinc Coating:50g-250g/Psm

Feedback:Within 24 Hours

Additional Info.

Packing:Export Standard Package or as Request

Standard:AISI, ASTM, BS, DIN, GB, JIS

Origin:China

HS Code:7210701000

Production Capacity:150, 000tons/Year

Specifications:

1. Thickness: 0.12mm-1.3mm

2. Width: 600mm-1250mm

3. Length: According to client's demands

4. Top paint: 15 to 25 um (5 um + 12-20 um)

Back paint: 7 +/- 2 um

5. Gloss: Normal or High gloss

6. Zinc coating: Z50-Z275G/psm

7. Inside Diameter: 508mm/610mm

8. Outside Diameter: 1000mm-1500mm

9. Coil weight: 3-8 tons

10. Payment: T/T, L/C, D/P, Paypal, Western Union

11. Trade Term: FOB, CFR, CIF

12. MOQ: 25 Mt

13. Package: Export standard package or as request

14. Shipment: By container

15. Standard: AISI, ASTM, BS, DIN, GB, JIS

16. Grade: JIS G3322, CGLCC, ASTM A755, CS-B

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day

- Q: Can steel coils be used in the production of medical equipment?

- Medical equipment production often incorporates steel coils. Steel, being a versatile material, is renowned for its strength, durability, and ability to withstand diverse environmental conditions. It is frequently employed in the manufacture of medical equipment such as surgical instruments, orthopedic implants, hospital beds, and diagnostic machines. The usage of steel coils as raw materials is commonplace in the production process. They can be processed and shaped into a multitude of forms, sizes, and components essential for medical equipment. By cutting, shaping, and welding the coils, intricate parts with precise specifications can be crafted, guaranteeing the quality and performance of the final product. Additionally, steel coils can undergo surface treatment to enhance their resistance to corrosion. This makes them appropriate for use in medical environments where cleanliness and hygiene are crucial. Electroplating or powder coating can be applied as protective coatings, offering an extra layer of defense against rust and other forms of degradation. Moreover, steel proves to be a cost-effective material, making it an appealing choice for manufacturers of medical equipment. Its availability and affordability render it a preferred option for producing high-quality medical devices while managing production costs. To summarize, the utilization of steel coils in the production of medical equipment is indeed viable. Their strength, durability, versatility, and cost-effectiveness make them an ideal selection for manufacturing various components and instruments utilized in the healthcare industry.

- Q: What are the different methods of tempering steel coils?

- There exist numerous techniques for tempering steel coils, each possessing unique advantages and disadvantages. Some of the most prevalent techniques include: 1. Air cooling: This method, the simplest and most commonly employed, involves heating the coils to a specific temperature and allowing them to cool naturally in the surrounding air. Although relatively speedy and cost-effective, this technique can result in uneven cooling and may lack precise control over the final properties of the steel. 2. Water quenching: In this approach, the steel coils are heated and then rapidly cooled by immersing them in a water bath. Water quenching provides a swifter and more controlled cooling rate than air cooling, resulting in increased hardness and strength. However, it may also cause heightened distortion and the development of internal stresses in the steel. 3. Oil quenching: Similar to water quenching, this method entails immersing the steel coils in an oil bath to rapidly cool them. Oil quenching offers a slower and more uniform cooling rate in comparison to water quenching, leading to reduced distortion and internal stresses. Nevertheless, it yields slightly lower hardness and strength than water quenching. 4. Salt bath quenching: This technique necessitates immersing the steel coils in a heated bath of molten salt for rapid cooling. Salt bath quenching ensures an even and controlled cooling rate, resulting in improved hardness and strength compared to air or water quenching. However, it requires specialized equipment and may not be suitable for all steel types. 5. Induction hardening: In this method, the steel coils undergo induction heating before being rapidly cooled using air, water, or oil quenching. Induction hardening permits precise control over the heating and cooling process, thereby achieving specific hardness and strength properties in desired areas of the steel. Nonetheless, it demands specialized equipment and is generally employed for specific applications or sections of the steel coils. Ultimately, the choice of tempering method relies on various factors, including the desired properties of the steel coils, the type of steel employed, and the specific requirements of the end application.

- Q: What is the average lifespan of a steel coil?

- Several factors can influence the average lifespan of a steel coil. These factors encompass the quality and type of steel utilized, the conditions in which the coil is stored or used, and the maintenance and care it receives. Typically, a steel coil that is well-maintained can endure for approximately 10 to 30 years. Nevertheless, this is merely an approximation, and the actual lifespan can be either shorter or longer depending on the aforementioned factors. For example, if the coil is exposed to severe environmental conditions, such as extreme temperatures or corrosive elements, its lifespan may be diminished. Regular upkeep and proper storage can significantly prolong the longevity of a steel coil. This entails ensuring that the coil is stored in a dry and safeguarded environment, frequently inspecting and addressing any indications of corrosion or damage, and conducting routine cleaning and lubrication as necessary. Ultimately, the average lifespan of a steel coil is contingent upon various factors, and it is advisable to consult the manufacturer or industry experts for a more precise estimation based on specific circumstances and conditions.

- Q: steel strutural

- IS-2062-92 STEEL IS FOR GENERAL STRUCTURAL PURPOSES. Fe410 is the specification of IS2062-1999. For properties and for more , please click: stainless-steel.in/productspeci3....

- Q: i have recently gotten into DIY and am planning on making my own knife. My question is what kind of steel would be good to use for heat treating if i plan on using water and not oil in the process.

- Go to junkyard get old leaf spring, cut out knife, start sharpening. Why waste time heat treating steel when the spring steel as already be done.

- Q: How are steel coils used in the manufacturing of consumer goods?

- Steel coils are used in the manufacturing of consumer goods as a primary material for various applications. They are commonly used in the production of appliances, automotive parts, construction materials, and packaging materials. The coils can be shaped, cut, and formed into different components or structures, providing strength, durability, and versatility to the end products.

- Q: What are the safety standards for steel coil manufacturing?

- To ensure the well-being and protection of workers, as well as the quality and reliability of the products produced, the safety standards for steel coil manufacturing have been designed. These standards encompass various aspects of the manufacturing process and include both general safety guidelines and industry-specific requirements. One of the primary safety standards for steel coil manufacturing involves implementing proper safeguards for machinery and equipment. This entails ensuring that all machinery and equipment used in the manufacturing process are adequately maintained, regularly inspected, and equipped with safety features such as emergency stop buttons and safety guards. Workers must also receive sufficient training on the safe operation of these machines and be aware of potential hazards. Another crucial safety standard is the utilization of personal protective equipment (PPE). Workers engaged in steel coil manufacturing must be provided with appropriate PPE, including safety goggles, gloves, ear protection, and protective clothing, in order to safeguard them against potential hazards such as flying sparks, noise, and chemical exposure. Additionally, safety standards for steel coil manufacturing emphasize the proper handling and storage of materials. This includes guidelines on how to safely lift and transport heavy steel coils, as well as regulations for stacking and storing them to prevent accidents and injuries. Fire safety is also of utmost importance in the safety standards for steel coil manufacturing. Measures should be implemented to prevent and control fires, such as regular inspections of electrical systems, proper storage and handling of flammable materials, and the availability of fire extinguishers and emergency evacuation plans. Furthermore, safety standards necessitate regular safety training and awareness programs for all employees involved in steel coil manufacturing. This ensures that workers are well-informed about potential hazards, safety procedures, and emergency protocols. Regular safety audits and inspections are also conducted to evaluate compliance with these standards and identify areas for improvement. Overall, the safety standards for steel coil manufacturing strive to establish a safe working environment, minimize the risk of accidents and injuries, and ensure the production of high-quality steel coils. Compliance with these standards is crucial for preserving the well-being of workers, protecting the environment, and upholding the reputation of the manufacturing industry.

- Q: How are steel coils protected from humidity?

- Steel coils are typically protected from humidity through a process called galvanization, where a layer of zinc is applied to the surface of the steel. This zinc coating acts as a barrier, preventing moisture from coming into contact with the steel and causing corrosion. Additionally, the coils may be stored in a controlled environment with low humidity levels to further protect them.

- Q: Bronze came before steel, right? thanks

- Yes, bronze was created a long time before steel. Steel came a long time after iron too.

- Q: Are steel coils used in the oil and gas industry?

- Yes, steel coils are commonly used in the oil and gas industry for various applications. They are utilized in the manufacturing of pipelines, storage tanks, and other equipment due to their strength, durability, and resistance to corrosion. Steel coils are also employed in the construction of offshore platforms and drilling rigs, where they provide structural support and ensure the safety and reliability of the infrastructure.

Send your message to us

0.12mm-1.3mm Thickness Prepainted Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords