Wholesale Floor Tile Polished Porcelain Tiles

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1382 m²

- Supply Capability:

- 138200 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

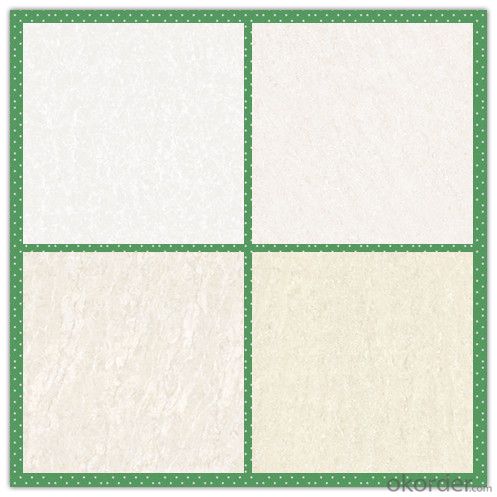

Key Specifications of Full Polished Porcelain Tile:

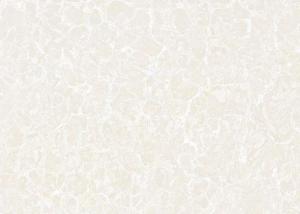

Full Polished porcelain tiles

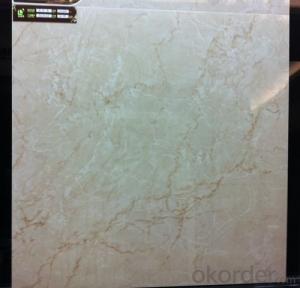

Great natural stone image and high glossy degree

Both silk printing and ink-jetting product available

Suitable for homes flooring tiles, high grade office buildings, high-grade hotel flooring tiles, government and corporate projects flooring tiles, deluxe clubs flooring and wall tiles

Water absorption:<0.3%

Sizes:600*600mm 800 x 800mm and 1200 x 600mm

Product features: resistance to fading, staining and discoloration, easy to clean

Package: carton + strong wooden pallet

Transportation: by sea

Advantages of Full Polished Porcelain Tile:

The porcelain polished floor tiles are non-slip and easy clean and with natural veins.

The porcelain polished tiles are hardness, which are resistant to acid and alkali, waterproof, wear resistance, dirt resistacne.

Good for indoor wall and floor decorations. Elegance, promote your decorate style.

The porcelain polished tiles with high quality are ideal for creating a beautiful feel in Hotel, House, Supermarket, Shopping Mall, etc

The porcelain polished tiles ,water absorption rate :<0.1%.< span="">

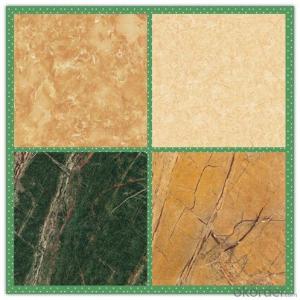

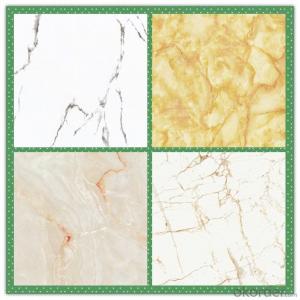

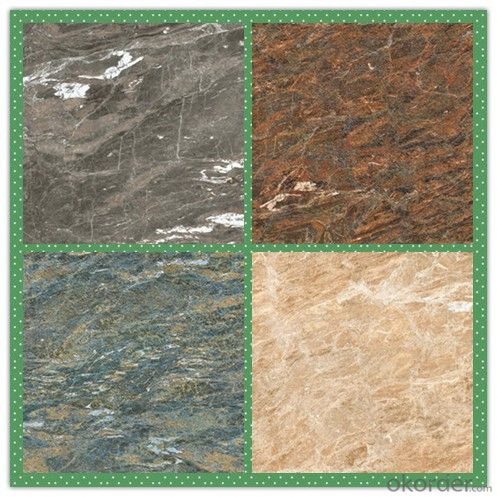

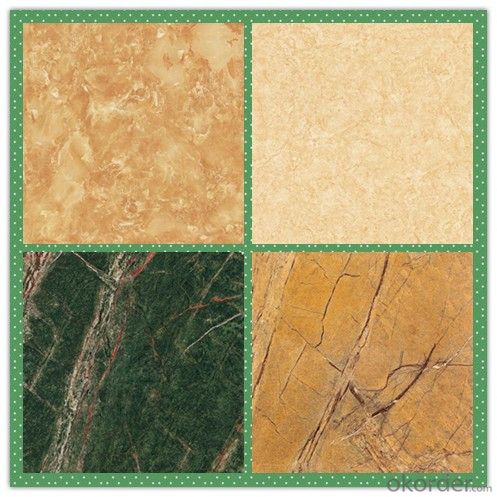

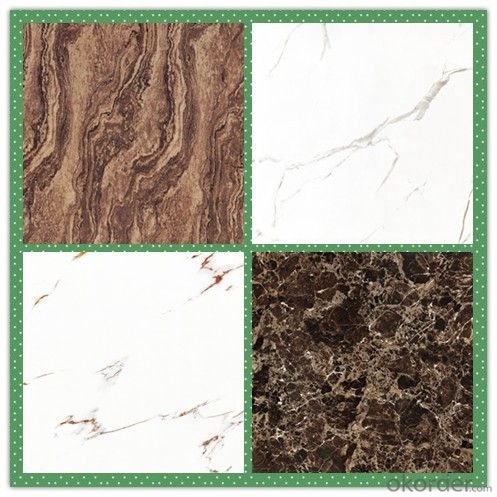

Many colors can be chosen.

The porceline tiles have 600*600,800*800 sizes, special sizes available according to request.

CE: GB/T19001-2008¬¬—ISO9001:2008

This is the best tile for hotel lobby flooring, airport, big project etc..

We have many different color and different design in this series. Please kindly check our website.

It's good for house flooring, super market, shopping mall, warehouse flooring, etc..

Our price is very competitive, and very good quality.

We have many certificates of our tiles

Main Export Markets:

Australasia

Central/South America

Eastern Europe

Mid East/Africa

North America

Western Europe

Product Pictures :

- Q:The walls of the decorative panels and tiles two materials in the interface where how to close the mouth

- If the two are in a plane, the operation is relatively simple, you can use natural sewing, sealing sealant closed, embedded in the T-shaped aluminum and other methods; if not in a plane, there are high and low, you can use L-shaped aluminum or stainless steel cover Prominent side.

- Q:Have very cheap lino in my kitchen. Am thinking of putting tile down myself.

- Putting Tile Over Linoleum

- Q:I am going to lay bathroom floor tiles in my bathroom but I have some questions before I start. 1. Can I lay the new tiles over the existing floor, which is vinyl flooring? Or do I have to remove that first? 2. If I have to remove the vinyl flooring do I have to add cement backer board? Or can I lay the tile right over whatever is under the vinyl flooring? 3. I have trim along that floor that I will be re-attaching, do I lay the tile right up to the wall or do I put a space in between the wall and the edge tile? Do I then grout into that space between the wall and the edge tile?

- I just retiled my kitchen floor and am in the process of doing the bathroom. Are you using the self stick type tiles? You don't have to remove the sheet vinyl if there is no damage to it. You would be best to lay the back board for a clean surface for the tiles to adhere to. If you are using the self stick tiles and don't want to lay the back board you can make the tiles stick buy applying a tile glue just a thin layer will make them connect to the floor permanent.

- Q:tiles to be applied in tub surround and ceiling

- Glass manufactres in all cases recomend using a white thinset mortar with additive for proper bond strench. Some suggestions include Custom Building Products megaflex Ultimate Thinset Mortar and Versabond Latex Modified Thinset.

- Q:Tiles of choice, how to see the quality of tiles is good or bad

- To see what to buy tiles, the ground or the wall is not the same as the identification method

- Q:How to identify the quality of ceramic tile and standard

- (10) Size deviation: Tile specifications can be measured with a caliper, good product specifications are small, paving products after the uniform, straight brick, decorative effect is good; poor product specifications deviation, product size is different; (11) color selection: the color of the external walls should be coordinated with the surrounding environment, high-rise buildings generally should not use white or too light-colored decorative wall, in order to avoid the building lack of texture: in the interior decoration. Floor tiles and inner wall tiles to coordinate with each other; (12) the choice of tile types: to use the specific environment to choose tiles, such as the living room should choose a larger size of polished tiles or antique tiles, and the kitchen and the best choice for non-slip, easy to clean the whole body bricks.

- Q:can I surface over my white tile flooring granet??

- If they are vinyl tiles stuck to the subfloor and you put another substrate, such as 1/2 cement board, yes you can. If the vinyl tiles are over another type subfloor, such as luan, then no, the vinyl and its substrate must come up and then the proper subflooring put down over the subfloor, correctly and then tile. If its a self stick tile, over slab, it must come up. If its a glued down vinyl tile over slab and bonded well, there are proper ways to put ceramic over this. If your doing ceramic over ceramic, and the ceramic is down well and no signs of cracks or loose tiles, again there are proper ways of putting ceramic ( or granite) over ceramic. Any questions you can e mail me through my avatar and heck my qualifications there. GL

- Q:I want to lay tile in my living room and I am on a fixed income. I have never done anything like this and so I do not know how hard it will be for me to do.

- We've done a lot of tile work and have learned a lot. Most books and websites have all the inof you need to know. If it's your 1st job, don't get too crazy w/the design, which can require more cutting. BUT, we have learned that the REAL CHEAP (like under .99/sq. ft.) tile from the superstores is hard to work w/since each tile it NOT the same size. This makes it hard to get straight grout lines. The tile we have bought from the tile stores have been better quality and youn can still find nice stuff in the .99 - $1.50 sq. ft. range. They are also a wealth of information! Good luck.

- Q:Just bought a new manual tile cutter, but it didn‘t come with instructions. Any help would be appreciated.

- === use your search box == how to use the workforce thd20 == please be aware that tile cutting is a learned art ... you have to go S L O W .. and cut at a fraction of an inch at a time if you want to avoid cracking the tile and breakage .... it is not lik

- Q:Hot tubs are in ground swimming pools are some times surrounded by border of tiles. The square hot tub has a side of length s feet. The tub is surrounded y a border tiles. Each square tiles measure 1 ft.to find the tile you have to use this: 4(s+1) now how is that expression same to (s+2)^2-s^2

- (s+2)^2-s^2 would provide the area of the tile border. It is equivalent to the area of the whole hot tub installation, including tile, minus the area of the tub itself. 4(s+1) would be a length in feet, and is not equivalent to any area. The perimeter of the hot tub is 4s, and the perimeter of the whole installation, including the tile is 4(s+2). 4(s+1), ignoring units, would give the number of tiles required for the border, which if multiplied by the area of one tile (1 ft^2) would give the area of the tile border. (s+2)^2-s^2 = s^2 + 4s + 4 - s^2 = 4s + 4 = = 4(s + 1) sq. ft. is also the area of the tile border. So they are the same, if you account for the difference in units.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wholesale Floor Tile Polished Porcelain Tiles

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1382 m²

- Supply Capability:

- 138200 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords