White Vinyl Floor Tiles

White Vinyl Floor Tiles Related Searches

Led Light Bulbs For Ceiling Fixtures Decorative Ceiling Plate For Light Fixture Ceiling Plate For Hanging Light Pvc Tiles For Walls Fiberglass Sheets For Roofing Decorative Lights For Ceiling Ceiling Lights For Sitting Room Ceiling Brackets For Lights Hanging Ceiling Chairs For Bedrooms 42 White Ceiling Fan With LightHot Searches

Used Foam Board Insulation For Sale Plastic Roof Tiles For Sale Magnesium Oxide Board For Sale Hdf Board For Sale sintra board for sale Gypsum Board Price Per Sheet In India High Density Mdf Board Suppliers Calcium Silicate Pipe Insulation Price 5 8 Type X Gypsum Board Price Calcium Silicate Board Suppliers In Uae Gypsum Board Price Per Sheet Extruded Polystyrene Insulation Board Price Polyurethane Insulation Board Price White Melamine Board Price Black Melamine Board Price Pre Laminated Board Price List Durock Cement Board Price Century Waterproof Plywood Price List Greenply Waterproof Plywood Price List Solar Inverter Mounting BoardWhite Vinyl Floor Tiles Supplier & Manufacturer from China

Okorder.com is a professional White Vinyl Floor Tiles supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest White Vinyl Floor Tiles firm in China.Hot Products

FAQ

- nan

- PVC floors and wood floors: wood floors can be broadly divided into three categories: solid wood flooring, solid wood flooring and laminate flooring. The wood floor is natural materials, synthetic materials have irreplaceable advantages, non-toxic and tasteless, comfortable, warm in winter and cool in summer.

- nan

- It is not necessary, the general plastic floor for the warehouse floor, fire and less dust

- That is, after the lime on the ground after the laying of plastic sheeting and then spread the concrete above the floor tiles on the floor so good? Do not put it or put it (plastic cloth)

- First, the purchase is the key to how to choose some of the moisture resistance of the ceramic tile, is the key to continue to enjoy the dry life in winter, there are six criteria for everyone to choose. The first: low water absorption rate of this tile usually have good moisture resistance, when buying, we can crack is tile surface observation, other glaze layer thick ceramic tile will also increase the moisture resistance of ceramic tile to a certain extent. Therefore, the user in the selection of ceramic tiles to watch the special table when the water content, water content less, good moisture-proof tiles, of course, the price is also high

- nan

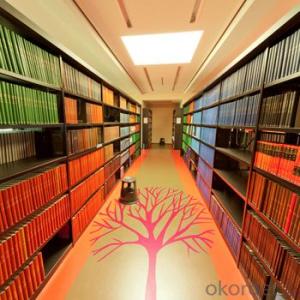

- 1 green environmental safety, such as now almost all hospitals are using plastic floor.2 colorful, beautiful and generous.3 convenient construction, the original ground, small space.

- nan

- Super slip: wear-resistant layer PVC plastic floor surface has a special anti-skid, and compared with common ground material, PVC floor (plastic floor) in the sticky water situations. More astringent, but not easy to slide into the water, which is more astringent. 6, fire retardant: PVC plastic floor fire index up to B1 level, B1 level that is very good fire performance, second only to stone. 7, waterproof: PVC plastic floor is the main component of vinyl resin, and water affinity, so its nature is not afraid of the water, as long as not long soak would not be damaged; and not because of high humidity and mildew

- nan

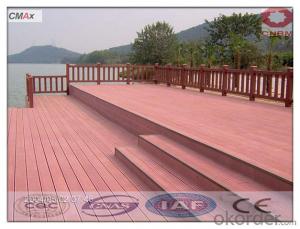

- In our minds the plastic floor are generally used outdoors, such as the use of polyurethane (also called PU) made of PU silicon PU stadium and stadium, and our common stadium plastic runway and so on, because the plastic floor will release some harmful substances, it is generally not used for indoor sports venues. But there is also a material PVC in our plastic floor, which is specially designed for indoor use.

- You master the family, to help me, I do not care about the color of plastic bags on the floor tiles, and how to rub are not wiped out, please help me master, I will add the score

- 3, polished tiles should be regularly waxing treatment, time interval of 2-3 months is appropriate.4, such as brick surface scratches, can be applied in the scratch of toothpaste, wipe with a dry cloth can be repaired.

- nan

- Thickness. The thickness of the PVC floor is mainly determined by two aspects, that is, the thickness of the bottom layer and the thickness of the wear-resistant layer. Currently on the market more common material layer thickness: 2.0mm, 2.5mm, 3.0mm, 3.5mm, 5.0mm these five kinds, and the wear layer thickness is 0.1mm, 0.12mm, 0.2mm, 0.3mm, 0.35mm, 0.5mm, etc.. In principle, the thicker the floor, the longer the service life, of course, the higher the price. Many consumers in the purchase of plastic floor when there is a big mistake, just look at the price does not ask the thickness, so businesses tend to take the thinnest products sold to consumers. Consumers should look for a professional business PVC flooring to buy.