Tower Crane TC7050 with stable braking

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of TC7050 Luffing Tower Crane

Feature: Tower Crane

Condition: New

Max.Lifting Load: 20T

Span: 70m

Place of Origin: China(Mainland)

Model Number: TC7050

Packaging & Delivery of TC7050 Luffing Tower Crane

Packaging Detail: Nude package

Delivery Detail: 25-30days

Specifications of TC7050 Luffing Tower Crane

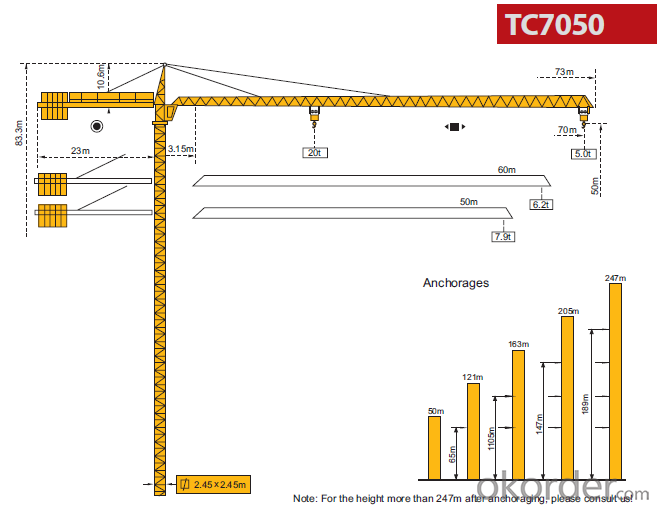

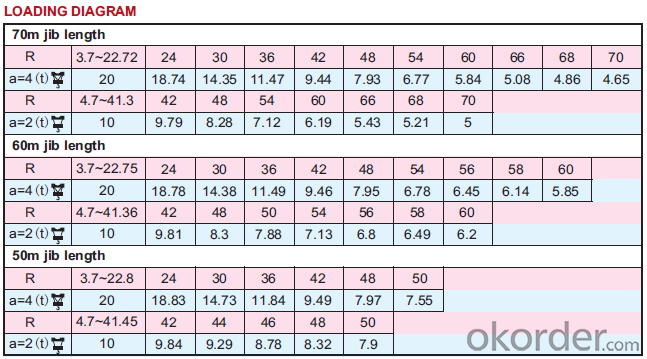

● Max. working range 70m, tip lifting weight 5.0T and Max. lifting weight 20T.

● Slewing mechanism equipped with two sets moment motor of HL 185.250.195 mechanism, stable braking

and less shock when shifting.

● Trolleying mechanism equipped with moment motor of 12DVF mechanism.

Free standing height (m) | 50 | ||||

Max height with attachment (m) | 200 | ||||

Working range can be adjusted(m) | 50、55、60、65、70 | ||||

Min working range(m) | 2.5 | ||||

Max lifting capacity(t) | 20 | ||||

Tip load @ 70m(t) | 5 | ||||

Hoist mechanism (VFD+PLC) | Falls | 2 | 4 | ||

Lifting capacity(t) | 0-5 | 0-10 | 0-10 | 0-20 | |

Speed(m/min) | 0-80 | 0-40 | 0-40 | 0-20 | |

Motor | YZPBF280S-4-75KW | ||||

Trolleying mechanism (VFD+PLC) | Speed(m/min) | 0-60 | |||

Motor | YPBE132M-4-11KW | ||||

Slewing mechanism (VFD+PLC) | Speed(r/min) | 0-0.6 | |||

Motor | YTRVF 132M2-4-9KW×3 | ||||

Climbing speed(m/min) | 0.45 | ||||

Counterweight(t) | 25 | ||||

Mast section size(L×W×H)m | 2.45×2.45×5 | ||||

Working temperature | -40-+60℃ | ||||

Total power (KW) | 115 | ||||

Power supply requirement (KVA) | 370KVA for generator | ||||

Cable type ( within 35 meters from site power source to lower electric box of tower crane ) |

| ||||

Startup voltage & current | 380V×95%=361V 408A | ||||

Rated working voltage & current | 380V 273A | ||||

Images of TC7050 Luffing Tower Crane

FAQ of TC7050 Luffing Tower Crane

Q: What is the principal to quote the right tower crane to the client?

A: First, we need to know clients’ requirements. Normally the following information should be clarified by the client: max lifting capacity, height (height under hook), tip load and jib length.

Second, we need to know what the foundation requirement from the client is. (Fixed/undercarriage/ undercarriage with traveling system), mast section type (panel/integrated), power supply source (voltage, ampere and frequency), the distance between the machine and power supply……

Third if there are special needs, we could suggest proposal according to clear data provided by the clients. End-user, as construction machinery buyer, knows the site situation well and should make decision, such as the machinery specification, type…….

Q: What about our tower crane's warranty?

A: Usually there is one-year quality warranty including main electronic parts (not including consumable parts). There are consumable spare parts together with whole machine and normally they are enough for one year.

Q: What is 3 main mechanism of the tower crane?

A: there are trolleying mechanism/ slewing mechanism/ hoisting mechanism.

Q: Can you equip with light on tower crane jib, monitor, remote control and anemometer?

A: Sure. All of these could be provided with extra cost upon the clients’ requirements. But according to general practice, remote control is not suggested because most of the operator feedback operation in the cabin will provide a wide working view.

To Lead The Revoluation of International Trade

- Q:I have recently mounted a Meiller MK 40 R / 2 crane on my truck and I wonder if my truck's hydraulic pump can support it without problems. I have a Mercedes-Benz 813 truck of 1987 and the crane is more or less the same years by the way. Should I change my truck's pump?

- Click here to find your answer

- Q:is was about making this game where this guy knows crane style

- There okorder /

- Q:I was told that this was taking place, so i would like to fax the info to the proper local

- Every city and every state has their own set of rules, where there are any. Also, the federal government has rules also. and the contractor has a set of rules also. And if you are in a union, they have a set too. So it depends on the country, state, city you are in. Do a search for Philadelphia Crane operator rules on google, for example. But i doubt any of them will say dogs are allowed. However, probably none of them will mention a dog at all, the assumption being that common sense will tell any competent operator that dogs and cranes do not mix. And I doubt any of them say pet snakes not allowed either. .

- Q:Equipment safety of tower crane

- Safe distance tower and transmission line is not up to the requirements of the tower frame door frame to design, erection principle to power erection, do not use metal materials, bamboo and other materials can be used. The distance between a bamboo pole and a power line shall not be less than 1m, and a certain degree of stability shall be taken to prevent the wind from blowing. The tower crane height and bottom bearing size ratio is large, and the center of gravity of the tower body, high torque, braking frequency, impact force, in order to increase its stability, we will analysis the main causes of the tilting of the tower crane has the following:Overloading. Different types of cranes usually adopts the lifting torque based control, when the amplitude exceeds the rated load weight increase or the corresponding weights, the overturning moment more than stable moment of it, it may cause the collapse of the tower crane.Two, inclined hanging. Slant weights will increase its overturning moment, the lifting point will produce horizontal force and vertical force on the crane, bottom supporting point will produce an additional overturning moment, and the stability coefficient is reduced, resulting in tower crane collapse.Three, the tower crane foundation is uneven, the ground endurance is insufficient, the perpendicularity error is too big, also can cause the tower crane to overturn the moment to increase, causes the tower crane stability to reduce. Therefore, we should proceed from these key factors to strictly check, check and check, and prevent major equipment personal safety accidents. State explicitly eliminated the model should resolutely prohibit the use of, in disrepair, tower crane in the identification of the repair, to limit the use of load, tower crane for the use of fixed number of years there is no uniform standards, opinions vary, different places have different provisions.

- Q:How often should the crane be inspected regularly?

- Crane safety supervision regulations twenty-fourth in lifting machinery safety regular supervision and inspection cycle for two years, elevator and manned elevator safety regular supervision, inspection cycle for a year.Eighteenth lifting machines should check the lifting machines regularly, including annual inspection, monthly inspection and daily inspection:I. at least one full inspection shall be carried out annually on the lifting machinery used.The load test can be carried out by lifting the heavy load which is equivalent to the lifting weight, and checking the safety performance of the mechanism such as lifting, running, turning and amplitude according to the rated speed.Lifting machines which have not been used for more than one year should be examined comprehensively before use.Crane in case of four or more earthquakes or major equipment accidents, outdoor work crane after more than nine winds, should be used before a comprehensive inspection.

- Q:What do you do after you made 1000 paper cranes. I know you string them up, but storing them is hard. Do you ceremoniously burn them or what? When can they be gone? This is the missing link in the story I want to know. I have 846 and I want to know what to do after I'm done.

- i know this big organisation in Japan and some of my frineds live there... if you are interested, I can give you the address and more details...etc

- Q:tell me how to do it, in the easiest way

- It's okorder /

- Q:What does the crane mean to the Korean people?

- The crane mates for life. Most birds do not and very few mammals. So it is a symbol of fidelity and faithfulness or loyalty to one's chosen mate. They are also very long-lived, up to 70 years in captivity, and so are symbols also of longevity. See nationalzoo.si.edu/Animals/Birds/...

- Q:How do they erect HUGE cranes without a crane?

- They use Hydraulics. I don't know if you have any understanding of Fluid power but a hydraulics system can lift up to 400% of its weight multiplyed by its density. There are other factors to consider such as cylinder size, flow, and pressure but these are usualy constants. For example: If the hydraulic fluid used weighs 5 lbs. per gallon and its density is .9 gram per cubic centimeter then 1 gallon of this fluid could lift 53.1441 lbs. A jack system is hydraulic

- Q:so yeah i know that cranes do the main work but i guess there are no such really toll cranes to do that with skyscrapers ?

- That is a good answer. Ordinary cranes build the steel frame to a height of perhaps 60 feet. The frame is designed so a specially designed crane can climb up the side (like climbing a ladder) to about 50 feet where the climbing crane can complete the frame to about 100 feet, then the crane can climb to the 90 foot level and build the frame to about 150 feet etc. Another method is the floor at about the 60 foot level is completed and extra strong. A crane is assembled on that floor and can complete the steel frame to about 100 feet where another extra strong floor is built. The crane at 60 feet is then dismantled and moved to the floor at the 100 foot level, or perhaps this is a second crane. Repeat until the full height of the building is frame work. As cranes are removed at the lower levels, more floors can be installed and some of the finishing work done. Either way, you can see why very tall buildings are very expensive. Likely both methods are used for some very large and very tall buildings. Neil

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tower Crane TC7050 with stable braking

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords