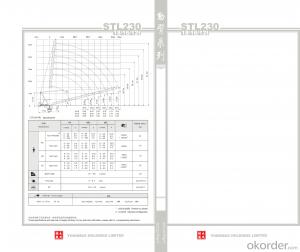

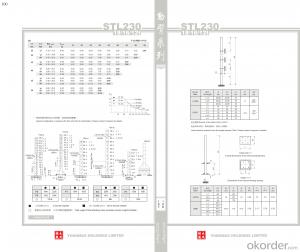

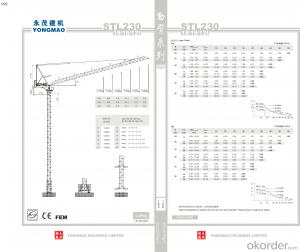

YONGMAO STL230 tower crane

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tower Crane Model Type:Luffing

Max. Lifting Capacity:18/16/12T

Tip load:2.0/2.0/2.0T

Arm Length:55M

Independent Height:48.2M

Founded in the year of 1996, Yongmao is one of the key suppliers specialized in manufacturing construction machinery and engineering equipment.

We currently offer a variety of tower cranes which are broadly classified under the Topless STT series, the ST series, the Luffing STL series and the Derrick QD series, as well as crawler cranes and modified vehicles.

Yongmao tower cranes have not only been working for various domestic projects like hydroelectric power plants, nuclear power plants, shipyard, wharf, bridge, aerospace etc. but also acting in numerous construction projects all over the world.

Yongmao appreciates the reliance and confidence given by its valuable users all over the world and feels very proud of its ability and capability to contribute value added services to its users both at home and abroad.

- Q:Some of my friends are trying to see what is the most creative, yet still meaningful way to ask a girl to prom. I decided to use 1000 origami cranes, and for those who don't know, the meaning (in Japanese lore) behind 1000 cranes is that the maker gets to make one wish, and its also traditional to give them to someone to wish happiness and prosperity upon them.

- I love the idea!!! it's really cute!!! I have the perfect idea...it just hit me! MY IDEA: Do you have a lake or some type of water flowing in your school yard? Trees too? If yes, then here's the idea: 1. Put some type of plastic wrap at the bottom of each crane so they can float on the water. 2. Hang those oragomis you've shown in trees. 3.Have one of your female friends get her and bring her to the area. 4. Then when she's wondering what's going on....here's where you come in. You said that 1,000 oragomis stand for a wish right? This is what you say with a crane out of the water in your hand: Behind these cranes, is a maker who has a wish. When you hand her the crane, she'll get the point. Hope she says yes! And if she says no, screw her! I wish the guy who asked me was that creative. Any girl should happy to have a guy go through this much just for her. Good Luck Dude!!!!!

- Q:i live in cali and these things are really starting to piss me off!!!!!!! I never noticed any before ( when i lived in colorado) but it seems lately that they are all over!!!! every time i open my damn door AT LEAST 5 of them come in! THERE SO GROSS with there big hanging legs! EWWWWW! Anyways, when will they go away and what do i do to keep them from getting in my house?

- The crane fly season only last for a month or so. There are years when they can reach almost plague proportions but within another 2-3 years their numbers should return to normal.. They can cause some damage to farm crops but the good news is that they are harmless to us.

- Q:What is the fundamental differences between Goju-ryu Karate and Fujian White Crane?

- Are these some sort of new pokemon?

- Q:Iv done some research and I cant seem to find a place that might sell jibs locally here in Phoenix. Iv been considering the ProAm DVC 200 crane but I would also like to see others in like a store. If anyone has any info it would be appreciated!

- I went down that path last year in the SF Bay Area in California. I could not find a store that carried any cranes or jibs - so I just started asking around. Stay away from any that use cables to keep the stage steady - we used one at a shoot - setting up is an interesting challenge. I thought I wanted the same unit you are looking at - and decided I needed to trust the crane a bit more with my HDR-FX1... I had to wait longer to save more $, but I really like the crane and tripod kit I ended up with... from Kessler Crane... I never got to see it before I bought it and I was, um... nervous... but I am glad I made the investment - and Eric Kessler is REALLY helpful and great to work with. One of the other cranes I looked at uses a heavy duty PA speaker stand as its tripod base. After watching light trees and PA speakers fall over because of leg failure, I could not bring myself to trust them to hold my camcorder. I can STAND or JUMP on the Kessler tripod and it does not budge. It is rock-steady and really strong. The Hercules head is silk-smooth and the crane-arm and camera stage are steady and easy to manipulate. After a little practice, it now takes me about 10-15 minutes from the time I start unpacking until I am ready to start shooting. That includes mounting the camcorder, setting the counterweights, mounting a portable DVD player with AV-in as the monitor mounted to the tripod-head so I can see what the camcorder is shooting and running the AV, headphone and LANC cables and making the whole thing pretty with velcro strips.

- Q:quick answer or i'll delete it!

- spongebob gives me a headache.

- Q:A family of cranes are at my house they are attacking my ducks and im scared they will kill them

- call fish and game or animal control. if they are on your property and are injuring or frightening your own animals, l am sure you are within your rights to take the matter in your own hands. harrass or chase them until they decide they don't like your property and leave on their own. l watched one kill a grebe on my local lake and fly off with it. l had no idea they would attack waterfowl. l think most states allow you to protect your private property from predation by wild animals. as long as they aren't whooping cranes (which they most likely are not), as soon as hunting season arrives (or sooner!), they may be edible... whooping cranes are the only federally protected ones. should a family of those arrive, consider yourself fortunate. but protect your ducks.

- Q:i need help with my essay,Question: Analyze the poem om terms of its structure, its themes, and its imagery. If youre stuck on themes consider God's absence indifference of nature, or the inronies of war. What is ironic about the poem? How does Crane criticize the romantic hero?

- The poem is ironic because the speaker is trying to make the soldier's family feel like he was meant to die in the war, even though no one's purpose in life is to die for their country. Good luck!

- Q:any kind of sayings

- You could just say whooping crane in another language, like Grue blanche (French) or Grulla blanca (Spanish). .

- Q:Do they need another crane to get the concerete blocks to the top? And how do they move the blocks from one end of the crane to another. This has been bothering me for some time so anyone who knows the answer I would love to hear it!

- Its simple man, The company produces the concrete blocks called as hollow blocks also, they are lifted up using man power or lifts or cranes, dont know what was difficult to you in understanding that.

- Q:type of dc motors used by electric train/subway,crane & fan.give a brief explanation to your answer?

- I believe that electric trains and subways use series motors when DC motors are used because the series motor has a torque vs. speed curve that provides high torque at low speed and low torque at high speed. Since power is equal to torque times speed, that is essentially a constant power mode of operation. I believe that mode is selected because it results in a smaller and less expensive complement of power delivery equipment and more efficient operation. Although it has been many years since DC motors were used extensively for cranes, I believe that series motors were used more than other types for the same reasons stated above. However, compound or separately excited motors may have been used for better speed and torque control at low speeds. Except for heater fans in vehicles, I don't believe DC motors have ever been used much for fans. Today, permanent magnet DC motors are used for all of the little motors in vehicles including the radiator fan that was formerly belt driven by the engine. A permanent magnet motor is like a separately excited motor or a shunt motor. The optimum DC motor for a fan would probably be a shunt motor because a fan requires increasing torque as speed increases. Today, computers are cooled by brushless DC motors.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

YONGMAO STL230 tower crane

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords