Tower Crane CMAX TC5013A Construction Machiney

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

Tower Crane is a machinery used for vertical lifting and horizontal delivering of building materials and any other heavy items during construction process. It can lift and lay down, horizontally shift, and rotate, so the working range is very large. The whole body can be fixed or movable.

Features:

1. All the components are designed to minimize the total number of trucks required to transport them.

2. The jib components can house the jib tiesto, which makes transport easier and quicker. Easy assembly of the jib and counter-jib ties.

3. The mechanisms are always used at full power. When hoisting, the speed is optimized according to the load and command. In distribution, progressive variation of speed and the maximum speed are adapted to the weight of the load. In orientation, there is controlled proportionalspeed with optimal acceleration and deceleration in accordance with the maximum admissible torque for the mast.

4. The auxiliary winch can be used on the derrick: this provides user with the possibility of a motorized derrick at the base of the machine.

5. DVF Distribution

The jib-footDVF mechanism is easily accessible in total safety.

Progressive speed variation by proportional control.

The speed depends directly on the controls manipulated by the crane operator.

To make driving the crane easier, 2 hard spots integrated into the controlsprovide better pinpointing of the speed.

6. RVF + orientation

The RVF Optima + orientation enables gentle rotating movements without jerking.

7. Fully integrated progressive control. Driving adapts to the behavior of the crane operator. The slow-down phase of the jib is managed by the frequency variator, Or by an inverted command in the slow-down phase, called a "counter-orientation" command.

8. The design of the electric sockets allows simple and quick connectionon all sites.

While operating or transporting, the cables are integrated and stored easily in the crane, increasing the service life of the electrical equipment and providing optimal conditions of safety.

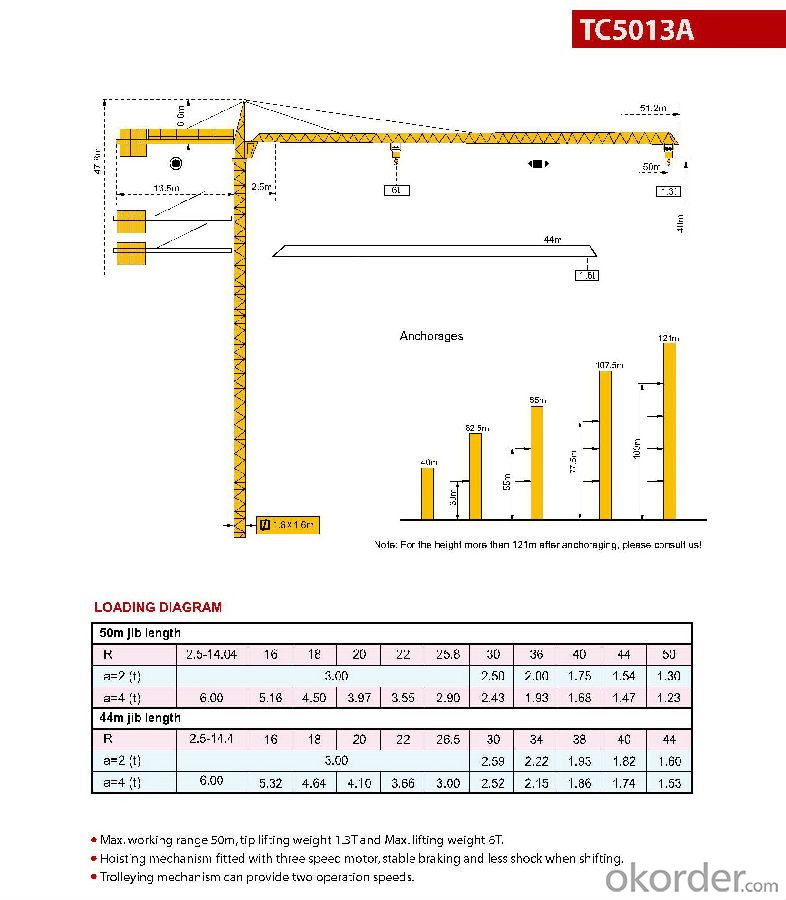

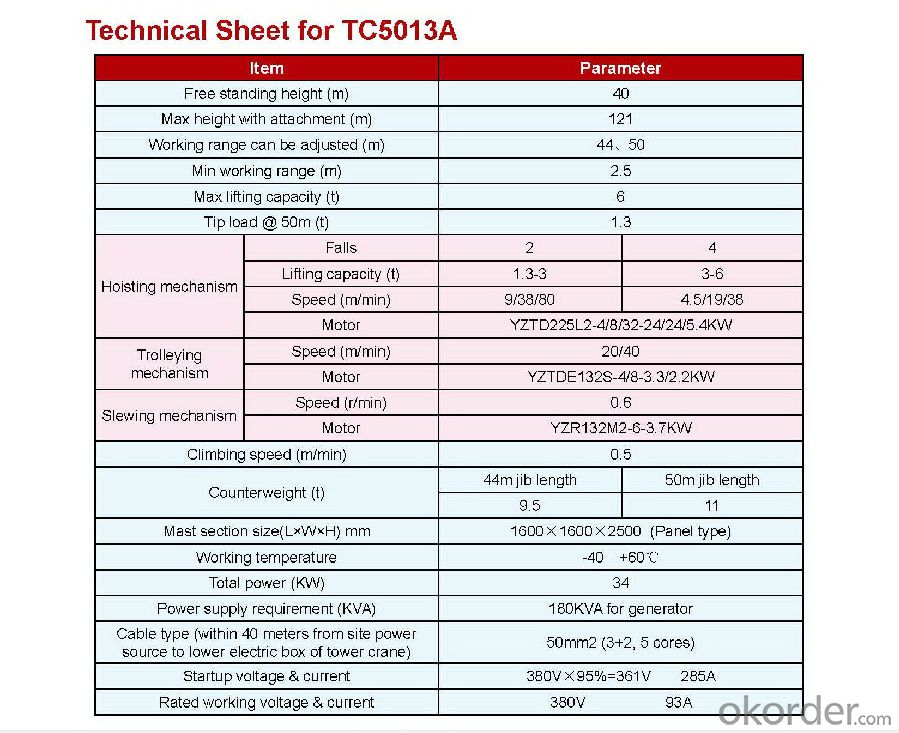

Specifications:

- Q:I loved Dr. Crane and his sexy glasses and eyes. Plus, I just love Cillian Murphy, haha. Is his character back in the Dark Knight, I heard he was...but I was wondering if anybody could confirm it?

- Yes for a short time in the beggining of the movie for like 5 minutes.

- Q:I don't like the cranes that use a wired pulley systems for controlling the camera.The crane will need to carry a 7 pound camcorder.

- Camera okorder /

- Q:Is there a certain direction and reason a construction worker will leave a crane facing a certain direction.

- not really they pretty much wanna just get home 2 their families

- Q:HOw to classify tower crane?

- From okorder / are divided into upper rotary tower crane and lower tower crane two broad categories.In which the carrying capacity of the former is high than the latter, in many Construction sites the tower cranes we have seen are On a rotary festival add up on the top of a high tower crane access. According to whether the move can move,tower crane are divided into: walking a line, and fixed ones. The fixed tower crane do not switch, installed in the block of concrete baseBasis, or installed in the form of X-shaped concrete foundation. In the housing construction generally use a fixed style.

- Q:my 7 year old son swears that a crane jumper is a type of animal...any one heard of this??

- I googled crane jumper and came up with nothing. Not to say there isn't such a creature, that could be a regional name for it, it might be called something else.

- Q:How many motors does the ZOOMLION TC6013A-6 tower crane use?

- Model: YZRDW225M-4/8 power: 24/24KW speed: 1420/725r/minDirect search {ZOOMLION QTZ80 (tc6013) _ crane Manual Part 1 (Part Two)}, can also be found.

- Q:What are the differences between the tower crane and the lift?

- Tower crane is a machine which transports construction materials within the construction site based on its radial range. Usually the radius of tower crane is around 50m to 60m. Capacity ranges from 3 to 6 tons Lift is only used for vertical transport of materials or people in certain building or construction site. Capacity ranges from 2 to 4 tons.

- Q:Where are gears used on a crane?

- Don't okorder

- Q:i will like to crane operator?

- You made a statement, you will like to crane (an) operator. Which operator is it you are going to like to crane? If you mean would you like to operate a crane, that is up to you. If you mean can you be a crane operator, that is up to an employer. You need to be employed as one, and that probably means training and experience before being allowed to operate cranes for him/ her.

- Q:It`s like a big box filled with toys and u insert a coin and then u have 2 handle the small crane to pick up a toy...

- a claw machine

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tower Crane CMAX TC5013A Construction Machiney

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords