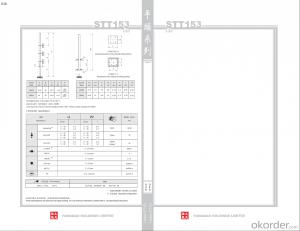

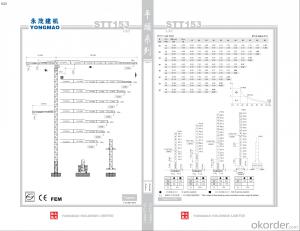

YONGMAO STT153 tower crane

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tower Crane Model Type:Topless

Max. Lifting Capacity:8T

Tip load:1.5T

Arm Length:65M

Independent Height:39.3M

Founded in the year of 1996, Yongmao is one of the key suppliers specialized in manufacturing construction machinery and engineering equipment.

We currently offer a variety of tower cranes which are broadly classified under the Topless STT series, the ST series, the Luffing STL series and the Derrick QD series, as well as crawler cranes and modified vehicles.

Yongmao tower cranes have not only been working for various domestic projects like hydroelectric power plants, nuclear power plants, shipyard, wharf, bridge, aerospace etc. but also acting in numerous construction projects all over the world.

Yongmao appreciates the reliance and confidence given by its valuable users all over the world and feels very proud of its ability and capability to contribute value added services to its users both at home and abroad.

- Q:More specifically, do Sandhill Cranes eat squirrels?

- No. Dont have the mouth for it.

- Q:I'll be graduating from a Korean language extra school in 1,5 years, and one of the teachers there is really amazing. Essentially, she has taught me the most compared to any other teacher there.Would giving her a 1000 cranes (and a bouquet maybe?) an appropriate and good 'thank you and goodbye' gift? Is it too little? Or overkill? She really means a lot so I want to give something!

- I think that gift would be perfect for a teacher! If I was a teacher and a student gave that to me i'd cry. Have you heard about that book of the 1000 paper cranes? (Can't remember the name) but it says if you make a 1000 paper cranes then you get a wish. Well anyways make sure you present the presents nicely. Like put the cranes in a pretty jar with a beautiful ribbon wrapped around it and get flowers that're her favorite colors.

- Q:Safety rules for tower cranes

- Three. Check after shutdown3.1 after the tower crane has stopped operation, it is necessary to select the suitable position of the barrier and the middle of the track when the turret is turned and the arm to stop along the wind, and then lock all the rail clamps.All 3.2 tower crane rotary mechanism with a normally closed or braking device, in the stop after the operation, the driver must remove the handle, release the brake for crane in the wind blowing in under the direction of rotation.3.3, the hook should be lifted to the minimum distance from the lifting wall, not more than 5m position, hanging on the hook is strictly prohibited. Not to take reliable measures, not by any means, limiting the boom rotate with the wind.

- Q:Who thinks William Shatner is adorable as Denny in Boston Legal? I do!! I just want to pinch his cheeks. He looks so lovable (in a chubby old guy kind of way. Lol.)AhahaAnd Shirley. She's so funny.Lincoln, suck. my. lobe. lol!Anywho...answer my denny question!!

- It's just you, you poor thing.

- Q:Basically what it says on top. Also provide maybe a video to prove it.

- Do you watch American Dad? And i think it would be difficult for it to actually work unless you modified it so no if its a traditional origami crane, but if you work backwards and made the wings of the crane to resemble a paper airplane then i think its possible

- Q:Can anyone help me interpret the poem Fear by Hart Crane? or North Labrador?

- Analysing Poetry Close reading may seem like a foreign and unfamiliar approach to analyzing a piece of text. However, it can often yield insights that will help you to create a unique paper developed from your own interpretation of the text. To analyze the work effectively, it is useful to concentrate on specific components of literature used to build and reveal the themes in the work. This process will help you explain how a passage relates to central themes in the text allowing you to reach an intelligent and creative thesis for a literary analysis. First, choose a passage (or a series of passages) that intrigues you.

- Q:What are the types of cranes?

- Three, crane according to the way of operation is divided into fixed and mobile. (1) tower cranes and cantilever cranes belong to fixed cranes. (2) bridge cranes, tire cranes, crawler cranes and railway cranes belong to mobile cranes. Mobile cranes are divided into rail and trackless two. Bridge crane is rail type, caterpillar and automobile are trackless. For example, the search network, the address is xxko, followed by com remember Oh, because this site is also facing the world, if you want to know a certain brand of crane, can look at its official website, this is also the line.

- Q:What is the allowable range of vertical deviation for tower cranes?

- The specified installation, construction, demolition of tower crane safety technical regulations in JGJ196--2010: the allowable deviation of verticality Tower: in the wind under no-load, the tower axis line should be less than 4 per thousand of the bearing surfaces of the lateral vertical deviation; after the attachment, the highest attachment point following the vertical deviation should be less than 2 per thousand. According to the installation state of tower crane, the deviation range of verticality is divided into 4/1000 or 2/1000. Tower crane maximum independent installation height (maximum installation height, does not need to be attached to the wall of the instructions specified in the free end) and height (the highest point of a tower crane attached to the wall above the height, body the following provisions in the specification of tower crane slewing) the vertical deviation range was 4/1000; tower crane attachment verticality deviation below the allowable range is 2/1000.

- Q:The truck has a Comprehensive Motor insurance cover. There is no exclusion in the policy in respect of tools of trade.

- The crane and the truck are one and the same vehicle, so I can't see why a claim on fully comp. wouldn't be valid. If this is not the case, then the crane IS the cargo, so surely the claim would go to the insurer of the crane, and not the lorry.

- Q:Type and specification of tower crane,

- QTZ40分4708、4808、500850 500863 5010 5013 551080 5513125 6015160 6018180 6524250 7030315 7050

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

YONGMAO STT153 tower crane

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords