Tower Crane CMAX TC4808 Construction Machiney

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

Tower Crane is a machinery used for vertical lifting and horizontal delivering of building materials and any other heavy items during construction process. It can lift and lay down, horizontally shift, and rotate, so it has big working range. The whole body can be fixed or movable.

Features:

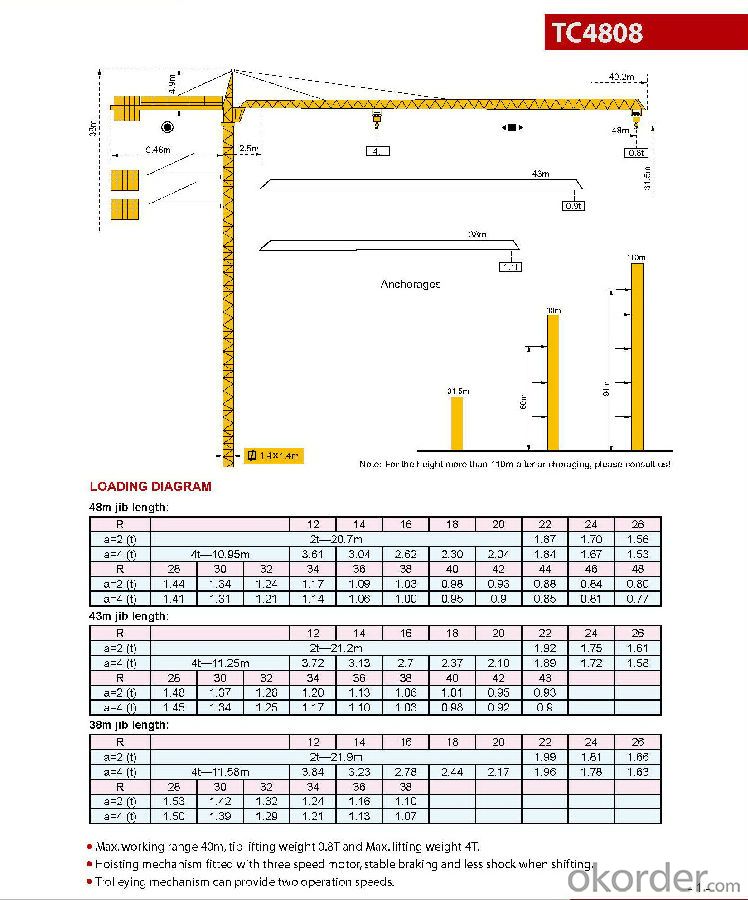

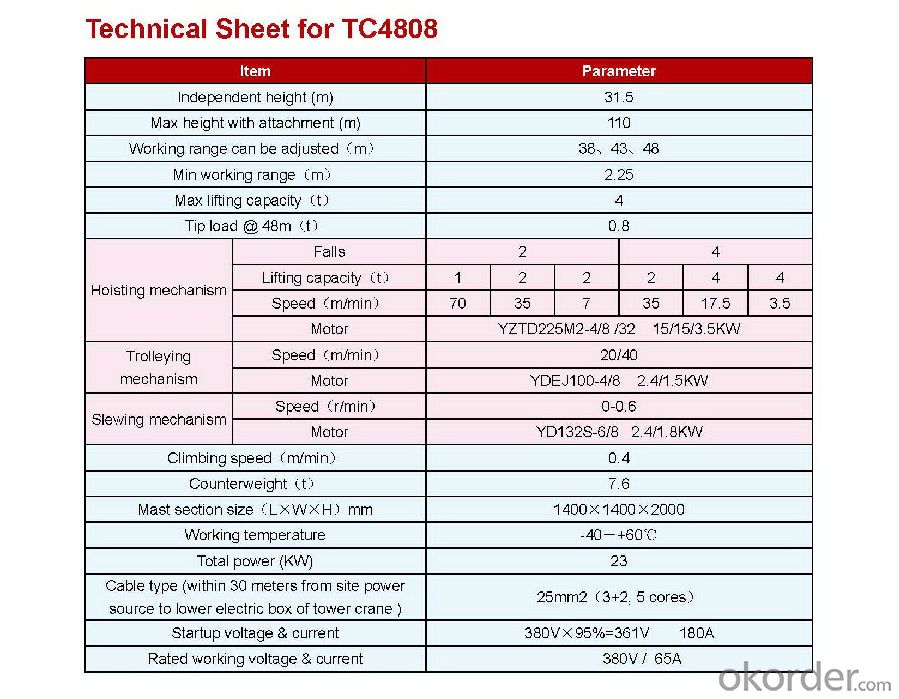

1. A universal model, suitable for various construction projects and working conditions.

2. Adopt standard section hydraulic lifting and connecting, can adjust crane height according to height of the building

without affecting the lifting capacity.

3. Use three-speed motor and mono-speed ratio decelerator, trolleying mechanism can provide two operation speeds: low speed for heavy and high speed for light load. Steady operation, stable braking and less shock when shifting.

4. With complete set of safety devices, with lifting height limiter, dolly range-change limiter, moment limiter, weight

limiter, circumgyrating limiter and so on.

5. Scientific layout, beautiful appearance design. The operator's room is set independently on one side, with good vision field.

Specifications:

- Q:would a tower crane be a first class, second class, or third class?

- The crane is balanced, with a fulcum somewhere between the ends. On one end, you have counter weight sometimes can be moved. On the end, you usually have the crane part, which can be trolleyed from the end toward the fulcum. If my memory serves me. a wheel barrow is a type 2, because the fulcum is on the end and the load is toward the middle. So this leaves you with a type 1 or 3. Try searching using the key word group lever type fulcum and I'll bet you get your answer.

- Q:She was editing some of his writings. She was appalled(prim proper Nebraska gal) by his lack of punctuation. He said he didn't have the time for it. He was right. Shortly after he died of TB. Do you ever feel that time is your enemy; that you have only so many years to make a difference?

- Wow. What a well-read intelligent question. I had forgotten that I had ever heard of Willa Cather. I really wish I did feel, or had ever felt, that I only have so many years to make a difference. Maybe I wouldn't waste my time so much. I think I feel now that it's too late to start. #sigh#

- Q:I know that you have to unfold the origami paper crane, but how do you find the surface area of it???????????????????????????/ please help...........

- Do you remember the formula for determining area? For a flat object (like your paper) the formula is Length X Width = Area. or LW=A So unfold your paper, and measure the length and the width, and simply multiply the two numbers. The resulting number will be your area. Of course, that is the area of the unfolded paper. Your crane in it's folded form will have a much different, and harder to find, surface area value.

- Q:Any difference?

- The crane part can be identical, but the vehicle part differs: in the former case it's a road-going (even multi-axle) truck, in the latter case it's an off-road vehicle with oversize all-terrain tires and appropriate traction and transmission capabilities. In either case, the vehicle must be stabilized on adjustable hydraulic struts before hoisting.

- Q:Is their a difference between a flamingos and cranes birds?

- their beaks and feather coloring

- Q:what does a paper crane represent/symbolize?

- A fun activity to do when you have nothing else to do!

- Q:does wing chun and karate come from the same white crane style of wushu/kung fu?

- Ng Mui, the Shaolin monk that survived to carry the research in Wing Chun, was a specialist in the white crane style, I have heard.

- Q:how dose a crane work

- No, crane can not lift itself (unless you mean can it pick another crane up, then answer is yes, of course: as you did not ask if the crane can pick itself up) You can also be a 'crane'. You can pick a dog up, maybe the same weight as you!.. but you can not pick yourself up (maybe part of you, like your leg, your arm) there are many different cranes, go to a building site and see (or see the web site I gave you below) Whuch crane you talking about? *Types of crane *Ancient crane *Medieval crane *Railroad crane *Mobile crane *Telescopic crane *Tower crane *Truck-mounted crane *Rough terrain crane *Crawler crane *Loader crane *Gantry crane *Overhead crane *Stacker crane *Floating crane Most NB for crane is its stability (it was found them tipping over): In order for a crane to be stable the sum of all moments about any point such as the base of the crane must equate to zero. In practise the magnitude and combination of anticipated loads is increased so that a crane should have a factor of safety against toppling of about ten times (it is based on leverage) hope it answered you, best regards Desert

- Q:I started to make 1000 paper cranes to make a wish come true and before I start I have a few questions. How many times can you make 1000 cranes to make a wish come true? Do you have to string them? And how long do you have to make them?

- I think it's a one time deal. You don't have to string them. You have as long as it takes. Look up Sadako Sasaki. She was a 12 year old Japanese girl who tried to fold 1000 cranes while in the hospital in the 1950's. She had A bomb disease, also know as leukemia. She got it because of the bombing of Hiroshima as a baby. She died after only making 650 or so cranes. It's a very good true story though.

- Q:i have a report on it and its due on the 20th

- They're loud. I've stopped traffic many times to let them walk across the road. They mate for life. I saw a Chinamen try to catch one so he could eat it once. True story.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tower Crane CMAX TC4808 Construction Machiney

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords