TCT5013 (6T) Topless Tower Crane From CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description:

The 6t climbing building construcion tower crane construcion tower crane in china features stable operation and reliable management due to the adoption of various advanced technologies. It is configured with diverse devices like the hydraulic self-propelling device, frequency converting slewing device and a series of reliable safety devices like hoisting height limiter, slewing range limiter and multifunctional limiter. It is thus easy for this heavy lifting equipment to control the hoisting capacity, load moment and trolley traveling range more precisely. Additionally, multiple electric safety devices such as anemoscopes and obstacle lights effectively prevent the breaking of trolley axles and wire ropes.

The PLC (Programmable Logic Controller) adopted by our aerial equipment can timely diagnose the cause of breakdowns. The frequency converter easily realizes continuously variable speed regulation and greatly improves the stability, reliability, and operability of the control system as well as the work efficiency of the flat top tower crane. In addition, the electric components are introduced from world-class enterprises including Omron, YASKAWA, Schneider (TE) and MEAN WELL. They ensure a low failure rate of the electric control system.

Main Product Features:

1. Widened equipment capacity and working scope.

2. Suitable for the groups of tower cross framework.

3. Noise relief stability with and combination amplitude range.

4. Can sustain height adjustment for occasional exceptional height construction procedures.

5. Large weight capacity, effectively solving high steel structure construction lifting capacity requirements.

Product Specifications:

Minimum Order Quantity: | 1 set | Unit: | set | LoadingPort: | |

Supply Ability: | 1000 set/month | Payment Terms: | TT OR LC | Package: | set |

Product Images:

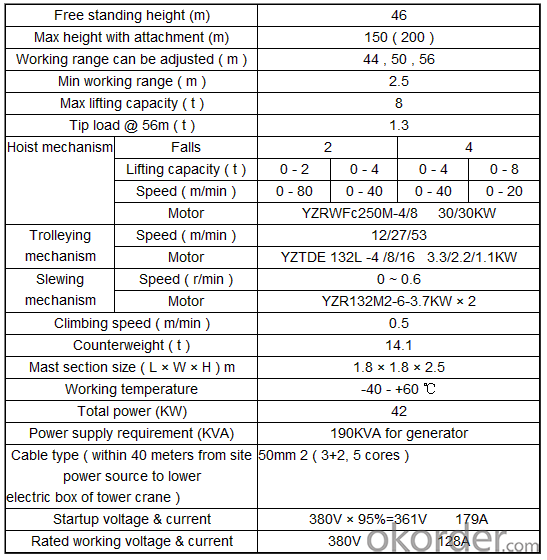

tower crane Specifiction

FAQ:

1.How about the shipment?

You can put 2 sets of of wheel loaders in one 40HQ container. The spare parts are packed with boxes.

The delivery time is 20 days.

2. What about your service?

We have our factory, we can meet customers needs as soon as possible.

We have first rate professional technology and provide good after-sales service.

3.After Sales Service

We offer the Preventative Maintenance and After Sales Service. For we strongly feels about the importance of supporting our customers and the product solutions we provide. Consequently we offer comprehensive maintenance options to prevent equipment issues before they become problems. Also we offer one year guarantee period.

- Q:Crane lifts a 600-kg bin with an initial acceleration of 2 m/s^2. Determine the force in each of the supporting cables due to this motion.?

- F = ma Assume the crate is uniformly loaded, both cables will carry the same force F(AB)(4/5) = (600/2)(9.8 + 2) F(AB)(4/5) = 3540 F(AB) = 4425 N F(BC) = 4425 N F(B-Crane) = 600(9.8 + 2) F(B-Crane) = 7080 N As a form of exchange, please remember to vote a Best Answer from among your results. This is not the same as like or thumbs up which are also nice and do boost points, but only after asker awards initial points with their vote.

- Q:i have 5 tower cranes outside my window at different construction sites and they all position their cranes the same direction at the end of the day. is there a reason for this.

- I would think it's wind-related. If they were all pointed differently, one would catch more wind and spin more. If they were close enough, this one may hit another. If they were all pointed the same, this would be less likely (although not guaranteed). They SHOULD be spaced apart sufficiently, though, so during operations there is no chance of hitting another. So, it's more likely because of something on the ground. Maybe at last drop off they were all pointing in the same direction?

- Q:I know they will leave because last year they left after a few weeks. I have seen that they normally leave after a month. They annoy me and I want them gone. They have been around since the end of February or beginning of March. Does anyone else have these in their house. It seems like they are leaving slowly usually there is like 1 or 2 a day in moms room but the last 2 days there have not been any. They have been in my room, just one a day it seems like and maybe one in the kitchen. We swat them or spray them and they die eventually but when will they be gone atleast for a little while?

- Crane flies are totaly harmless to humans.They fly for some time and fall down to earth.Ants will take them away.These flies never byte or sting. Pet Cats like to play with it and catch it.They will disappear after some time. Do you know that crane flies spend most of their lives underground in their larval forms, which are known as leatherjackest?. Leatherjackets were very common round here, and are a favourite food of the local crows .These leatherjackets transform into crane flies.Summer is their growth time.

- Q:A crane lifts a 425 kg steel beam vertically a distance of 117m. How much work does the crane do on the beam if the beam accelerates upward at 1.8 m/s^2? Neglect frictional forces.a.) 3.4 x 10^5 Jb.) 4.0 x 10^5 Jc.) 5.8 x 10^5 Jd.) 4.9 x 10^5 JSolved as W= mgh but obviously that is wrong. Where do I go wrong?

- You have the right idea, the answer is d. EDIT: Well I actually read the rest of the question (sometimes I get an itchy trigger finger!), and the net force should be found first, the net force includes the weight and the tension in the crane's cable (so you need to find the tension): ∑F = ma = T - mg T = m(a + g) = 425kg(1.80m/s? + 9.80m/s?) = 4930N So the net force is the sum of the tension in the cable and the weight of the beam, or: F = T - mg = 4930N - (425kg)(9.80m/s?) = 735N Then, the work done by the crane is: W = FΔy = 735N(117m) = 8.95 x 10^4J Does not match any of your choices, so I am perplexed! Maybe someone will straighten me out. Apologies if I failed to help.

- Q:i need to write a 2 pg paper on this, and i cant even begin

- Stpehen Crane used interesting literary techniques such as colorful metaphors which can easily be identified in eg like knowing eyes which represent the people of Dunnet (ammons, 84). Another literary technique he uses often is irony which is seen in chapter with Mrs. Todds variety of personality which shows how Mrs. Todd has this varied personality(eden, 141). Other literary techniques shown are comparisons and contradictions, dramatic personification and powerful paradox.

- Q:Are the creators of the Karate Kid movies apologetic about the white crane defensive stance?

- Why should they be? That stance is from an art that is practiced by a small number of practitioners in Okinawa known as Hakutsuru, which means White Crane. It was hollywood-ized... so what? The original movie was written by a practitioner of Goju Ryu, who trained in NYC under an instructor from the Bronx named Kao Loong Ong. He knew there was a link between White Crane and the development of Okinawan Karate. Robert Kamen trained with Kayo, as he is known, who is Chinese and is well known in NYC's China Town. If they should apologize, hollywood must apologize for their misrepresentation of SO many things - insults to practically all the cultures of the world.

- Q:About tower crane torque limiter with 4 limit switches, each play a role, thank you

- The maximum amplitude control: when the weight exceeds or prohibit increase load rate of more than 105% or greater than the maximum amplitude (amplitude limit) output control, allowing the car to be near range by car distance to increase amplitude is prohibited.Minimum range control: when the amplitude is less than the minimum amplitude (amplitude lower limit), the output control allows the car to move to a distant range, i.e., to increase

- Q:A crane operator must ensure that the load is within load chart ratings for _________ and the __________ of the crane.A. Boom length; CenterpointB. Boom length; Load RadiusC. Center Point, Load RadiusD. Center of Gravity; Load Radius

- B. The load radius is the horizontal distance from the center of rotation of the crane to the center of gravity of the load being lifted. The load radius is a critical consideration when determining what size crane is required for most lifts. There is generally a chart that tells what that machine will lift at any boom length,

- Q:if someone have formula for that, one telescopic crane is lifting and i know about the boom lenght and redius,then how i can calculate the angle,if crane crane angle indicator is not working.thankyou.

- Boy! You really need to get the angle indicator fixed and calibrated! There are ways to estimate, but they are inaccurate and therefore not safe, if you have not got the expierence to do it. Don't use the crane for any load close to your SWL!!! An addition: unless you want to measure your reach, i.e. the distance from the crane pedestool to your load, then you can calculate the angle, but you don't need to anymore as you now know what the distance of your lift is and therefore you can look up the SWL on your chart. Get it fixed.

- Q:I heard on the TV and found it hard to believe. I mean, they are soooo goddamned stupid and dont look like they could muster up the intelligence to bite someone anyway. Also my pet rat catches them and eats them when they blunder into the house and he seems fine! On TV it said they were one of the most poisonous creatures of their species! Should my bullsh1tometer be off the charts?

- crane flies are perfectlt harmless to you and your pets, they are just annoying.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

TCT5013 (6T) Topless Tower Crane From CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords