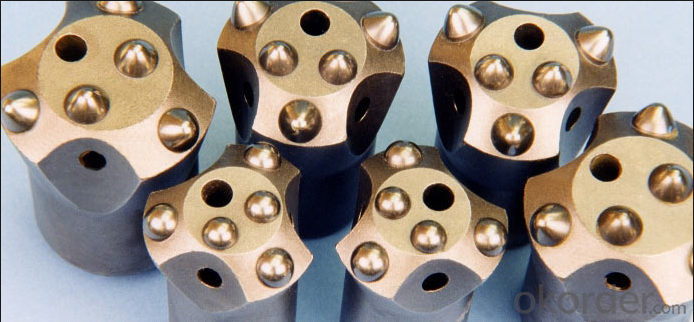

taper buttton bit from China high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are specialized in rock drilling tools,such as taper button bit, thread button bit, Integral drill rod, DTH bit, DTH hammer, Air leg rock drill, Excavator Mounted rock driling and splitter, expansive mortar.

Product:

Taper button bit as small hole bit is different with thread button bit as long hole bit to use taper match with bit with rod to be used for air leg or hand held jack hammer driller in quarrying, and mining. Tapered button drill bits are widely used for drilling hard or very hard work. In addition to tapered button drill bits, we provide tapered chisel drill bits, as well as taper drill rods, etc.

Description of button bit:

Our company supply all kind of button bits with Rope thread

R32-43MM, R32-45MM, R32-51, R32-64, R32-76;

T38-64, T38-76MM, T38-89, T38-102MM;

T45-76MM, T45-89MM, T45-102MM;

T51-89MM, T51-102MM, T51-127MM etc.

all face design, flat face, drop-center face, normal body and retrac body.more

Specification of button bit:

Tapered button bits Diameter(mm) | No*button diameter | Flushing hole | Weight | ||||

mm | inch | Front | Gauge | Angle | Front | Side | |

32 | 1 1/4 | 1*8 | 3*8 | 35° | 1 | 1 | 0.24 |

33 | 1 19/64 | 2*7 | 5*7 | 35° | 2 | 1 | 0.26 |

34 | 1 11/32 | 2*7 | 4*7 | 40° | 1 | 1 | 0.29 |

35 | 1 3/8 | 2*7 | 5*8 | 35° | 1 | 1 | 0.33 |

36 | 1 27/64 | 1*8 | 3*9 | 40° | 1 | 1 | 0.37 |

36 | 1 27/64 | 2*7 | 5*8 | 35° | 1 | 1 | 0.37 |

38 | 1 1/2 | 1*8 | 3*9 | 35° | 1 | 1 | 0.38 |

38 | 1 1/2 | 2*7 | 5*8 | 35° | 1 | 1 | 0.38 |

38 | 1 1/2 | 2*7 | 5*9 | 40° | 2 | 1 | 0.38 |

40 | 1 37/64 | 1*8 | 3*9 | 30° | 1 | 1 | 0.40 |

40 | 1 37/64 | 1*9 | 3*10 | 30° | 1 | 1 | 0.40 |

40 | 1 37/64 | 1*9 | 3*9 | 35° | 1 | 1 | 0.40 |

40 | 1 37/64 | 2*7 | 5*9 | 35° | 1 | 1 | 0.40 |

42 | 1 21/32 | 1*8 | 3*9 | 30° | 1 | 1 | 0.43 |

42 | 1 21/32 | 1*9 | 3*10 | 30° | 1 | 1 | 0.43 |

42 | 1 21/32 | 1*9 | 3*9 | 35° | 1 | 1 | 0.43 |

42 | 1 37/64 | 2*8 | 5*9 | 35° | 1 | 1 | 0.43 |

Company Profile:

CNBM is the largest state-owned enterprise in China building material & equipment industry. Up until October of 2011, our total assets exceeded RMB 190 billion, with 130,000 employees and over 300 subordinate companies. In the year 2012, we are ranked as No. 365 in World Top 500 Enterprises by Fortune, and No. 2 in global building materials industry, second only to Saint-Gobain.

FAQ:

1. Q: Can I get some samples?

A: We are honored to offer you samples for quality check.

2. Q: Do you have the products in stock?

A : Yes , We have sample for several models now could supply to you.

3. Q: What’s the delivery time?

A: It usually takes about 25 days to produce an order. But the exact delivery time might be different for different orders or at different time.

4. Q: Can I mix different models in one container?

A: Yes, different models can be mixed in one container, but the quantity of each model should not be less than MOQ.

5. Q: How does your factory do regarding quality control?

A: Quality is priority. Rock drilling tools workers always attach great importance to quality control from the every beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment.

6. Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. Our company is world top 500, that is the biggest supplier and manufacture in China, having a good reputation around the world.

7. Q: What's the payment you accept ?

A: As usual our payment is T/T, other payment can consider.

As the largest manufacturer and exporter of building materials in China, we avail ourselves of this opportunity to approach you for mutual-beneficial cooperation. If you want to know more, pls contact me freely.

- Q:Which is better, a white drill or a black drill?

- Color is not directly related to quality. High quality, fully ground, high-speed steel drills often appear in white. Of course, the rolling bit can also be made white by grinding the outer circle. The reason is that high quality, in addition to the material itself, in the process of grinding quality control is quite strict, the tool surface will not appear burns. Black is an oxygen treated drill. It is a chemical method to increase the durability of the tool after placing the cutting tool in a mixture of ammonia and water vapor and after 540-560C degrees of thermal insulation.

- Q:What drills should be used to drill holes with diameter 5mm and depth 65mm? Urgent! Thank you!

- You don't know what material you need to drill, what is the material, or how hard it is,Ordinary material on the ordinary line, and if the material hardness, then you have to use M35 cobalt or alloy drill.

- Q:Who can do this? Put the drill into it

- The method of assembling drill bits is incorrect. The easiest way is to clamp the hammer hammer down the legs, with the left index finger on four set head forward, pointing to the direction of the motor to pull the thumb and ring sleeve. Take the drill with your right hand

- Q:What bit is better for drilling 304 stainless steel?

- Cobalt cobalt high speed steel processing of stainless steel drill bit: high cobalt drill (M35 drill, M42 bit).. where M42 bit is best performance

- Q:Why can an electric drill pinch the drill so tightly?

- There are three teeth scattered drill chuck, the teeth are retractable, with different thickness of the drill bit used to hold, in the roots of teeth (in the rotating disc, invisible), a spin silk, when rotating clockwise, wire like screw the teeth out, caught the drill bit, otherwise return to loosen the drill bit.

- Q:How to change the drill bit of impact electric drill?

- Install the drill bit: or the handstand impact drill, the left hand down to the plastic ring, the right hand with the drill, rotating around the insertion

- Q:Is the drill fast to feed, easy to break, or slow to feed, easy to break?

- Therefore, the drill feed should be moderate, not only to ensure good broken, but also to ensure that the drill bit of cutting time.

- Q:What is the drill bit of the percussion drill, please?!

- The diameter of the drill is in units.

- Q:The whole alloy drill often breaks

- Drilling with carbide drills is the most afraid of bit feed instability, vibration and pulsation, which is the most likely to break the drill bit. If the drilling is not guaranteed, the cemented carbide bit can be used instead. The body of this drill is made of tool steel material, but only hard alloy material is inserted in the cutting part. The drill will not break the drill even when it is drilling.

- Q:How does the CNC lathe drill center to detail?

- That is, there are other tools on the lathe, such as cylindrical lathe tool, on the basis of other round turning tools, the outer surface of the cylinder to maintain XThe direction is constant, Z direction retract, then take a look at this knife, X direction of the mechanical coordinates of X1 (must be mechanical coordinates),The X value of the excircle tool you use to measure the caliper is X2 (diameter value), and the mechanical sitting of the drill bit in the center of the workpiece is calculatedStandard calculation method: X=X1-X2/2, and then the mechanical knife drill bit moving coordinate value in the way of using the handwheel, tool cutting tool number in direct input bit 0, and then click on the soft keyboard "measurement", so as to better.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

taper buttton bit from China high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords