Submersible Sewage Pump 50Hp, Discharge Sewage Pump, Float Switch Submersible Sewage Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

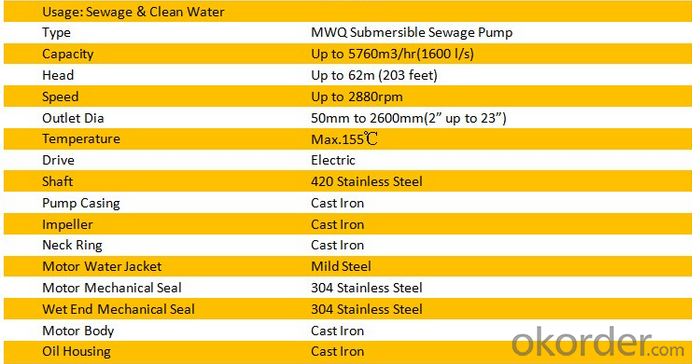

Item specifice

Submersible Sewage Pump 50Hp, Discharge Sewage Pump, Float Switch Submersible Sewage Pump

Company Introduce

My company has more than 40 years history, is the China general machinery pump industry association member units.

My company has organized product research and development team, experienced high, intermediate technical staff.

Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.

Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

My company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.

Relevant product standards (enterprise), metrology, standardization management system, etc.,

have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and aftersales service, are performed according to the system management standard.

Application

This series pump is widely used for sewage treatment of city construction discharge for architecture projects, hotel, mine, pond, dyeing and printing, paper making and textile industries.

It is the ideal tool for transportation of sludge, slurry, living sewage, feces and stale wastes, solid grains fiber, paper chips, sandy soil etc.

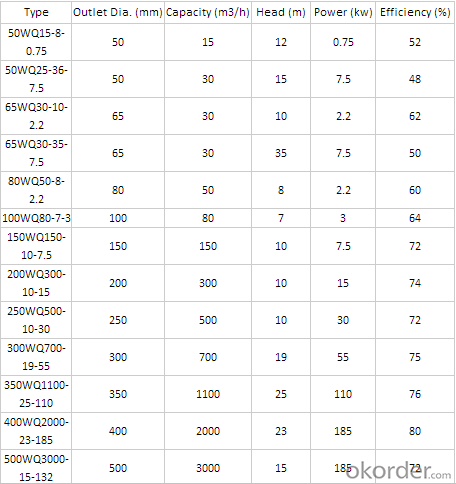

Model Description

100 WQ 50-30-3

100: Drain aperture (mm)

WQ: Submersible sewage pump

50: Capacity (m3/hr)

30: Head (m)

3: Power (kW)

Operations Conditions

1. The medium temperature should not be over 60oC, the density 1200Kg/m3, and the pH value within 5-9.

2. During running, the pump must not be lower than the permitted lowest liquid level.

3. Rated voltage 380 V, rated frequency 50 Hz. The motor can run successfully, only under the condition the deviations of both rated voltage and frequency are not over ± 5%.

4. The maximum diameter of the solid grain going through the pump has not to be larger than 50% of that of the pump outlet.

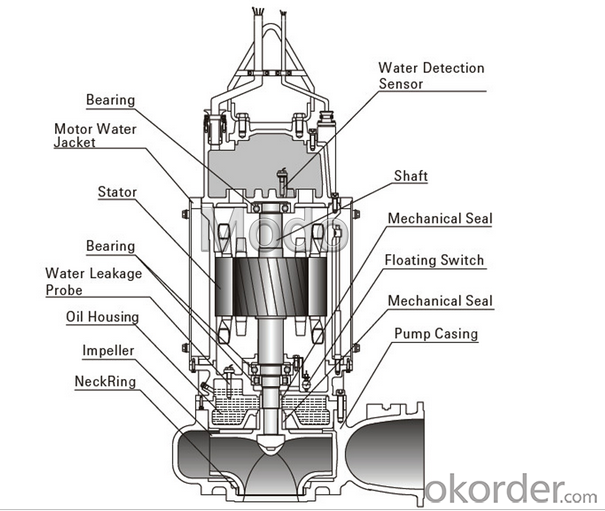

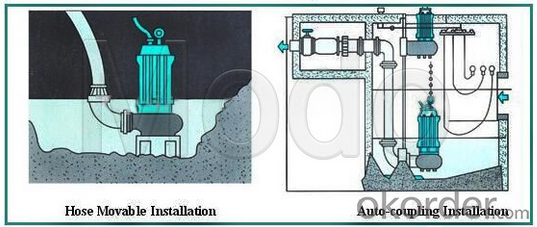

Pictures Show

Trading market

Transportation

- Q:Mercedes 2000 ml 320. I changed radiator and water pump now car only runs half as worm than it used to. So now heat blows cold to little warm depending on how cold out side

- If there is an air pocket in the system you will not get hot heat from the climate control system. If the heater worked OK before you replaced the water pump it's probably a stubborn air pocket. You need to raise the front of the car a good 12 and then rune the motor for 20 minutes with the radiator and reservoir caps removed. Have the climate control set to the hottest setting with the blower turned off or on low speed. Top up the coolant as the air bubbles purge. The heat coming out of the vents should be hot at idle, if it only gets hot when you rev the motor you still have an air pocket. Then try revving the motor up and down to 2,500 rpm and squeeze the upper radiator hose at the same time to get the air pocket to purge. If you can't get the air out you will need an expensive Airlift vacuum fill tool for the cooling system. Some vehicles such as Infiniti's will not purge the air with out using the Aitlift brand fill tool.

- Q:When the pump is connected in parallel, will the head and flow change?

- Parallel pump should lift the same head, the flow is the sum of the flow of a single pump.

- Q:i used my water fountain pump for the first time yesterday and I've had it for 10 years and i used it yesterday it worked with the water and everything was fine!then the next day i wanted to turn it on , it went on it started vibrating but it wasn't pumpingwhen i had it on the other day the water was dirty but it was workingi cleaned it the filtershould i put vinegar to clean it ?and what else should i do!??? Help :#92;thank you!

- Debris is probably blocking the impeller ,a wheel that spins inside the pump,and moves the water through,you might have to take it in for servicing to a repair shop,if you aren't mechanically inclined to do it yourself.leaf litter,or a twig can get inside the intake port and wedge itself in the wheel,and keep it from working ,try backflushing the pump,forcing water the opposite direction through,and see if this dislodges the blockage first,then if no luck,you'll have to dismantle it to get the blockage out Make sure you handle the pump carefully.if all else fails,you could try whacking it with a hammer,and see if that jolts it free.It is pretty old now,and may be just time to get a new one,10 years is a good life span for one of these pumps.

- Q:I have a fairly new jetted tub. I stupidly used bubble bath 2 days before and have since read that it is not good, but just because of the amount of bubbles, not that it will actually harm the system. The electrical circuit is not tripped. I hear this clicking but the pump doesn't turn on. Any ideas? Do I need a new pump?

- Your pump either has a jammed impeller or the coupling is broken. These pumps are lubricated by the water flowing through and when you are pumping bubbles, you're not pumping water. Hopefully the tub was installed so there is reasonably easy access to the pump cavity.

- Q:Pump performance parameters have three sets of data, how to understand the flow, lift, flow speed

- Mainly expressed the ability of the pump, mainly as a basis for selecting the pump users.Lift represents the performance of the pump to boost water pressure. Such as the pump head H=38 meters, that the pump outlet pressure normal to 0.38MPa.The flow rate represents the water supply capacity of the pump. Such as 100 m3/h. The general flow pump design, and the corresponding flow, little significance.

- Q:An engineer is given the job of designing the water system for a tall building. He decides to locate the pumps at ground level and feed the entire building from there. If the top floor of the building is 236 m above ground level, what must the pressure be at pump level?

- 23.6 E5 Pa

- Q:the pump is pumping hot wtaer from the hot water tank around the domestic hot water system, i.e to taps and shower.

- These pumps can have their own bearing or they may rely on the bearings in the motor. Most of these are anti-friction bearings that have a limited life. Also if the pump runs dry it can over heat and seize.

- Q:ok some one put sugar in my gas tank i had to replace my fuel pump and now i have sludge that's eating th inside of my radiator hoses and my water pump went and of course that's timing driven and my timing belt is awful tight i cant put a finger in between it ....and my car is not car water so i cant drive it and i don't have money to blow to take it to a shop any help u can offer will help and i know i am going to replace my water pump and info for when i do that will help and answers to the sludge (its like a Vaseline) and how to find out if its in my motor or my brand new radiator ? me plz i am a 18 yr old girl with knowledge about cars and have friends to help me and my mom so any helpp will help and is better then none

- Correct okorder /.... Sugar in the tank, is a MYTH. The problem you have, is NOT due to someone putting sugar in the tank. Secondly, your fuel system doesn't connect at all to your radiator. So, replacing a fuel pump has nothing to do with sludge in your coolant. So, is the sludge in the coolant, or the fuel? Because honestly, your question makes no sense right now. Edit: I didn't correct your spelling. I corrected the fact that you are incorrect about sugar in the tank doing anything. IF anything, it would have clogged your fuel filter. Not your fuel pump. Go read the article.

- Q:A Pump is direct driven by a 25 HP 900 rpm electric motor at rated load. In order to to double the quanitity of water delivered, it would be necessary to substitute a motor rated at____HP at____rpm. ans. 200 and 1800. not sure how they came up with this answer...whats the equation???

- N = (95 H.C)/D Where N = rev/min D = diameter of impeller over blade tips in metres H = total head in metres C = constant. C depends on the shape of the pump and normally lies between 1.05 and 1.2 Later edit. I'm not sure if you are aware of it but each impeller has it's own characteristic performance curve.

- Q:i have an underground water tank, my jet pump went out again, got a new one, waiting for the guy to come install it. i got an old fashioned iron hand pump, for when the electric, or the pump goes out again, i can pump out water. got pipes, fittings, foot valve. i just dont know what kind of base to make ,to bolt pump to, over the pipe that will come out of the ground. any ideas?

- you can make a wooden floor cover using a treated good lumber of 1 X 6 for the floor and 2 X 6 lumber for the floor joist. assemble the 2X6 lumber for the floor joist. depending on the top area of your water tank. arrange the floor joist at 0.60 meter spacing and 1.2 meter braces. after that, use 1X6 lumber as flooring with at least 2 cm spacing between lumber. as on the base of your pump, you can reinforce it by adding 2X6 braces. use a lug bolt depending on the size of the slot at the base of your pump then bolt it on top of the 1X6 flooring. its better if we can draw it here to make it easier to understand and explain i dont know if this can help much because we havent seen the actual situation of your tank and your pump.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Submersible Sewage Pump 50Hp, Discharge Sewage Pump, Float Switch Submersible Sewage Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords