Steel Pipe Fittings Butt-Welding 180° Long Radius Return Bends

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features standards and products of our butt welding fittings:

Features of butt welding fittings:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of butt welding fittings:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

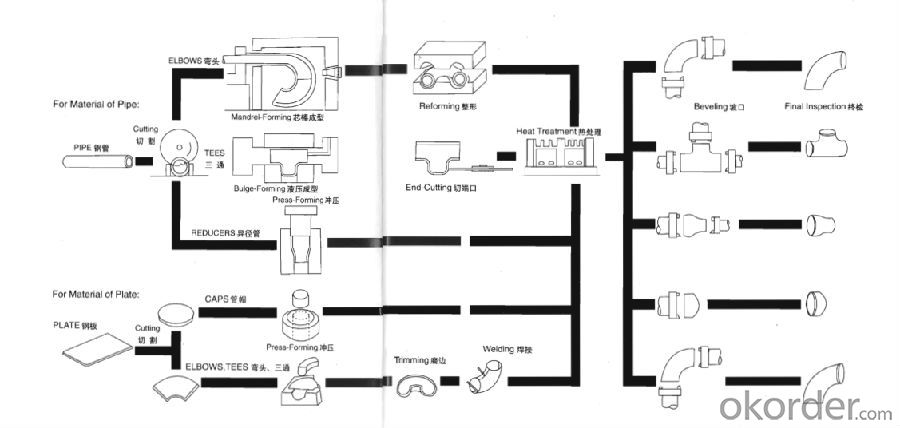

Manufacturing method and process:

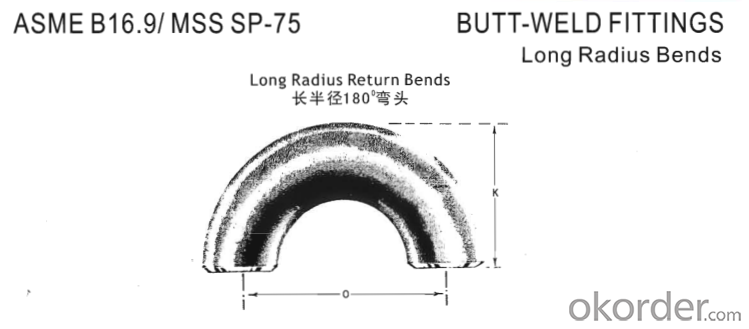

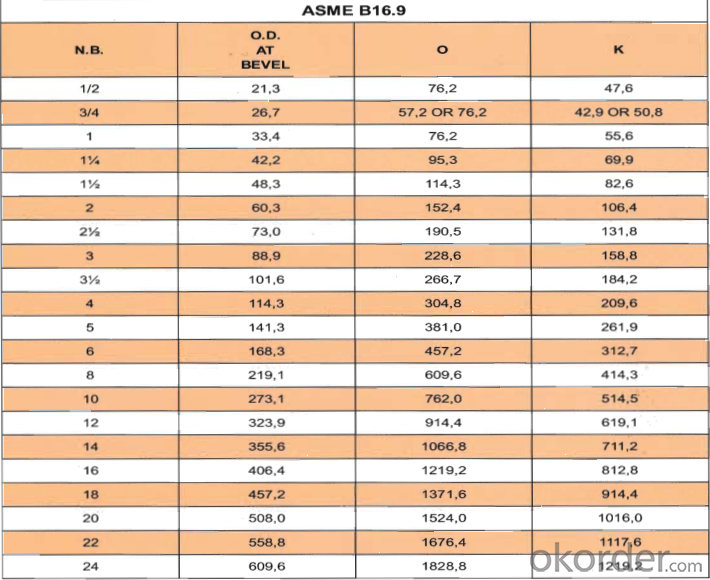

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

180° Long radius bends:

Packing of butt welding fittings:

FAQ of butt-welding fittings:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:Phoney Tony used to love posing with factory workers wearing the fluorescent vest, hairnet, safety goggles etc. What a class act he was!

- Tell her that if you will call her that and then she will get mad or drip hot sauce in her mouth

- Q:Wouldn't it be funny if Cincinatti came out of the tunnel and all the offensive players had face shields?

- 1996 mazda protege get a mazda 2 it ? 6,000 just new so 2008 or 2009 would be ? 4,000 to ? 5,000 give the your old car and cause it over 10 years old u get ?2,000 off so it ? 2,000 or ? 3,000

- Q:BQ: Which My Bloody Valentine tracks feature his best guitar work?

- Do you mean a penetrating oil like WD40 or do you mean a lock or padlock?

- Q:my microlab m-666 (2:1) has a great ammount of trible out put. my brother has a speaker of ALTEC LANSING ACS45.1, it gives a heavenly BASS output(this speaker is celibrating its 15 year birthday!!!!!) but the bad newz is my microlab has a disgusting bass out put. expert sez that my trible is WAY to0 much. so balencing the trible might do it!! but it has no trible EQULIZR!!!!but, if i make my writing paper into an elephant trunk and insert it to the SUBWOOFER output, then it sounds ALTEC lansing. but still, the out put is not enuff!! still it doesn't make an earth quake to our house. if ne 1 undrstand my prob, plz HELP me( amplifire won't help)and dont b funny, this is serious, this is my first speaker!

- Why don't you use taxpayers money to study on the internet Then you might be successful in life and you will not have to use facebook all day to have fun Instead you will be chilling in NY, going to the best clubs, going back to your million dollar penthouse in your $100000 dollar car. just a suggestion But if you want to figure out how to break the system, learn about what you are doing and study it well, because there is a lot of money in the IT field peace If you don't understand a proxy. and can't understand how to read the man's instructions and do what he says then maybe you should really stick to your studies. There is no easy way to do it PROFESSIONALS that studied in school created the blocks what chance do YOU have against them?

- Q:Ok so every night around this time I get a horrible urge to urinate, it lasts until the tank is empty I'd you know what i mean and that takes a LONG time since only a little comes out at a time, I have to goto the bathroom about 15 times before I start urinating (can't hold it) on the rug, it is disgusting and it's really been bad for over a month now, the funny thing is when I lay down the urge is so bad it feels like the urine is about to just come out, rather when im sitting up it's not bad. Also once I fall asleep I don't wake back up in the middle of the night to urinate that's it until the noting. I also noticed I have a very hard time urinating during the day I have to get it an extra push, something i never had to do before in my 20 years of life, I'm very young for this kind of stuff, I don't know what it is and I have been to the urologist he said there was nothing wrong, im getting worried. I appreciate all of the help, thanks very much.

- It would depend on many things such as how big is the facility, how many rooms need to be covered and to what degree, how many break glasses and sensors, is it monitored by a central station and not least local/state codes. It would need a survey.

- Q:I was talking to this jerk online, and I said I didn't want to date someone who felt the way he did about an important issue.He said I didn't realize you were such a lightning rod.What does that mean?

- Just change the end fittings where they attach with a 3/4 to 1 adapter. Ideally, you should use a sweat fitting, but since you aren't *soldering friendly* you could use one of the newer styles such as what in in the link. That one is a *Sharkbite* fitting that you can get at the Home depot, but Lowe's carries their own version called *Gatorbite* and there are other non soldering ways to do it as well, such as compression fittings as shown in the second link. Al

- Q:I'm making a door alarm, what MUST it have?I already have; low cost, easy to use, brightly colored/visible, not too small or big (to act as a deterrent)can you suggest some more please?

- if the green is ONLY on the copper pipes, its oxidation and no worries.if its elsewhere, it could be mold and thats dangerous! use bleach to kill it.

- Q:If there was a fire and I went to pull the fire alarm what if I read the directions out loud to help me to understand what to do and to make me more confident? Also what if my hand slipped and I had to pull the handle again and I said uh-oh? Do people ever talk out loud to themselves or to a friend standing nearby in this situation? Why is it that someone would do this silently while another one would talk out loud and still get the job done? If a kid were to pull a fire alarm in a fire would they be more likely to talk out loud since it is a new thing for them? What would they say out loud to themselves in this situation to help them?

- If you read the pedia article you cite, it says that all attempts to detect Nemesis have failed, despite using really sensitive techniques.

- Q:If your smoking in a house with smoke detectors will it go off or does it only detect smoke from fires? Can they tell the difference between the two?

- Stop panicking, I used to fall asleep on the floor in front of the fire all the time when I was a kid, never did me any harm apart from a smacked bum from my mum!

- Q:Every time we turn on the heat, there is a terrible oil smell that comes up from the basement. It gives everyone in the house headaches, irritated throats and eyes. Can anyone explain why and how to resolve this?

- He's pavement after 8 years of dirt road.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Pipe Fittings Butt-Welding 180° Long Radius Return Bends

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords