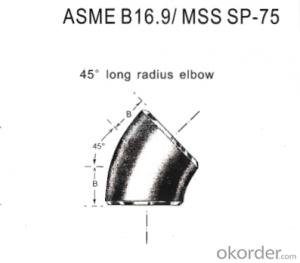

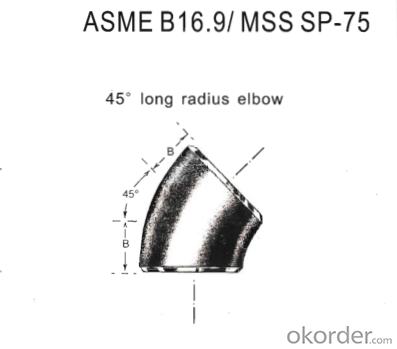

Alloy Steel Pipe Fittings Butt-Welding 45° Long Radius Elbows

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features standards and products of our butt welding fittings:

Features of butt welding fittings:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of butt welding fittings:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

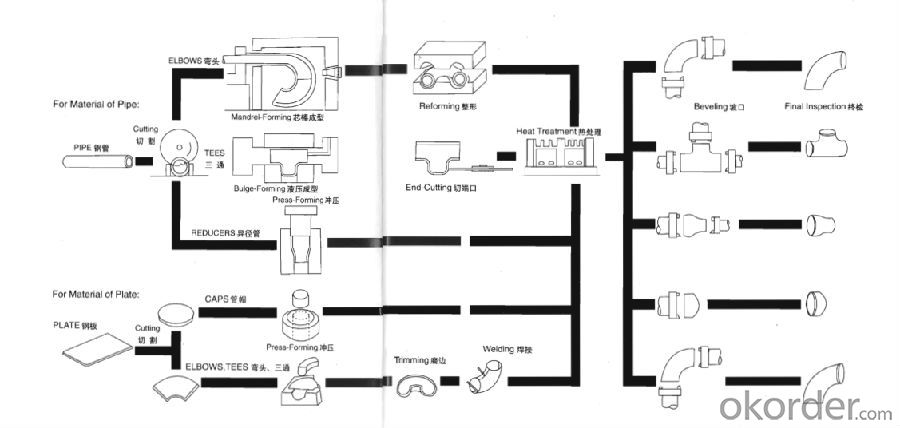

Manufacturing method and process:

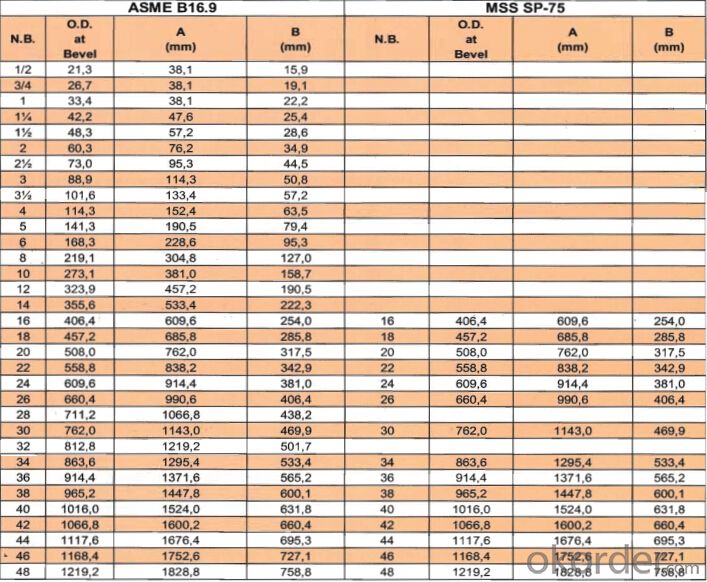

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

45° Long radius elbows:

Packing of butt welding fittings:

FAQ of butt-welding fittings:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:What are the pros and cons of each

- I will add on compres air, see if you can blow it out.

- Q:I have a lightning rod pizza oven with specialty pepperoni and mushroom conductors. I am concerned about lightning burning the cheese, however. How can I prevent this? Also, any suggestions for keeping rain from making the crust soggy? Thanks!! :)

- my car was doin the same thing the other day, i thoaght it was the shows, or ball joins, hell i dint have a clue..also sometimes at a dead stop my car would make that noise as i pressed the gas..monthsand months this was happening, i found out last week what it was..lift your car up, or anyone who has a lift, mine was the front axels, where a rackopion was put in, and the place where u get it alined was loose, tighten it up, nomoreproblems, just tell someone u take it to that story, have them check all the bolts..if thats not the case, check shows, balljoints

- Q:We have a fire and CO detector that I removed from the ceiling to paint it.After I removed it I saw in tiny print to shut it off before removing. I really am not familiar with what it looks like off hand as I'm at work.It is sensitive to the light being turned on and it goes off every time we turn the light on. It says warning, carbon monoxide levels are high, then it says carbon monoxide levels are 0 PPM and stops.They are all new and all of them have gone off at least twice since moving in and only when the light is turned on. They go off within seconds.How can I get this one to stop going off EVERY time? Like I said, I'm at work and not familiar off hand with what's on it. I'd hope there's some kind of reset button? Is it too close to the light? It's maybe 2-3 feet away from the light.I'm sure I can figure it out eventually, but it's just weird to never have a problem this bad with it until now.

- i would bet that you have asthma. it may only happen on rare occasions i would lay money that not having the reaction when you switched to glass was merely a coincidence. if i were you i would go to your doctor and tell him about the reaction (leave out what you were doing at the time) but let him know that its a reaction that you have sometimes but very rarely and get an inhaler for those emergency situations. also to ther person who chose to answer a question that they obviously know nothing about, none of those methods of smoking require anyone to burn plastic and if you are burning plastic you are doing it wrong.

- Q:When I put a DVD, CD or anything into the drive, it sounds like it spins for a moment and then stops. On the My Computer it wont even register that I put something in it. My MediaSmart also says there is no disc when in fact there is one. The button to open the drive works perfectly. What could have happened in the past few days to cause this?

- Why don't you just burn down the building and skip the easy stuff? Grow up.

- Q:i'm going to blow smoke out the window, but my fire detector is like 2 yards away from my window. so, i need to make sure it won't go off, or do you think it will?if i just turn on my lighter will it go off? i don't really know anything about itthanks!

- Take a scuff pad and scrub it down good with lacquer thinner. Then paint. Just like any other surface. My dad owns a fire extinguisher shop and I have painted a few of them. The biggest thing is to make sure the tank is clean.

- Q:The third red wire on the harness used to interconnect fire alarms so that they all sound when one is activated. Can I use the Ground wire to interconnect the two?

- In a house - can be air in the pipes or a loose hanger that allow a pipe to hit a rafter or wall board. In a car - generally a loose hanger or missing. Sometime a bolt missing on the joining pipe fittings. Your personal pipes - bad digestion, eating spicy foods, too much beer.

- Q:Detailed point. I'd like to add some knowledge about it.

- (1) pre assembledThe pre assembly of the sleeve type pipe joint is the most important step, which directly affects the reliability of the seal. Special pre assemblies are usually required. The small diameter can be pre joint in a vise. The concrete method is to use a joint body as the mother's body and press the nut and the sleeve tightly onto the pipe. The utility model mainly comprises a sleeve type through pipe joint, a clamping sleeve type end through connection head, a clamping sleeve type three way pipe joint and other patterns. The author found that even if the same batch of goods of the same manufacturer, the tapered holes on these joints are often different in depth, resulting in leakage, and this problem is often overlooked.The correct approach should be to connect the end of the pipe with what kind of joint body, and the corresponding connection end with the same type of joint pre installed, so as to maximize leakage problems can be avoided.

- Q:k so i have found a robin egg, it is not cracked and it was on the ground, not in a nest and when i picked it up it was warm. so i put it in a box with a blanket and i have a heater next to it at 60 degrese and it is about 2 and a half inches away from the blanket but it is in a box. im afrade while im at school it might catch something on firewill it?

- Can you walk with a stick cuz your going to be blind. The pain you are experancing is a normal reaction to stupidity. You need a few days to suffer so you wont do this again. Maybe tomrow you can park jets without hearing protection. What you have done is stare into the sun Your doc may be able to perscribe some eye drops if not try viseane The stingwill go away in a week or two good luck and dont do that anymore

- Q:crappy will i get in trouble by the fire fighters if i paint it the same color . thankx

- Greetings from the northern plains, with not the least bit of amusement over your suffering what we've always dealt with. First, to get it out of the way, do not call this guy back again, as he is ripping you off. I believe it's called profiteering, like the bastards that would spike the price of plywood to $100 a sheet before, or after, a tornado or hurricane. (I would perhaps make this a hobby to go after the guy, his reputation, and his business, as he is one low-life dude, and I can be nasty.) Nuff. Drain cleaning chemicals are intended to dissolve, or at least loosen, clogs such as grease, hair, soap, etc., but not ice. Yes, ice can form in drain lines, especially if not nicely sloped (where there's a sag in a straight run), or at a fitting. Once started, it can accumulate - that's how icicles are formed, a little a time. If the drain pipe leaving the kitchen (likely 1 1/2 pipe) is enclosed above the garage, I'd open up the garage ceiling (if finished), or perhaps the chase it's boxed in with, and warm the pipe with hot air, to get things going. Once done with that, get some insulation under the pipe (in effect getting the pipe into the envelope of the house, not below it). I agree that the yellowish leak may well be the drain cleaner, but the leak also betrays - a leak. Any and all fittings should be inspected. Worst case is actually a cracked drain pipe from the ice, and steel drain pipe (very not likely). PVC or ABS plastic drain pipe is quick and economical to cut out and repair, so buck up. (Personally, I would also exit with an access panel for the next time, not just sealing up with a drywall repair.) In the coldest climates, some might use pipe heating tape as a preventative measure, but I suspect you aren't in one, just caught in this nasty weather. The tape, however is not a good solution to an already-frozen line - it's too slow.

- Q:Are the fire hydrants where you live red, yellow, white, or another colour?

- First of all, be sure to have nice lighting. An overhead isn't enoughhave a night table lamp and night light in the bedroom and a night light in the bath room. Be sure the room has a comfy chair and throw, candles, magazines, booksmaybe even some chocolates. Empty a few drawers in the dresser too.In the bathroom put out your best towels and soaps, add candles and a nice rug. Most of all make sure both rooms are uncluttered (little or none of your personal items) and spotlessly clean!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alloy Steel Pipe Fittings Butt-Welding 45° Long Radius Elbows

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords